Soybean ACE inhibitory peptide and preparation method and application thereof

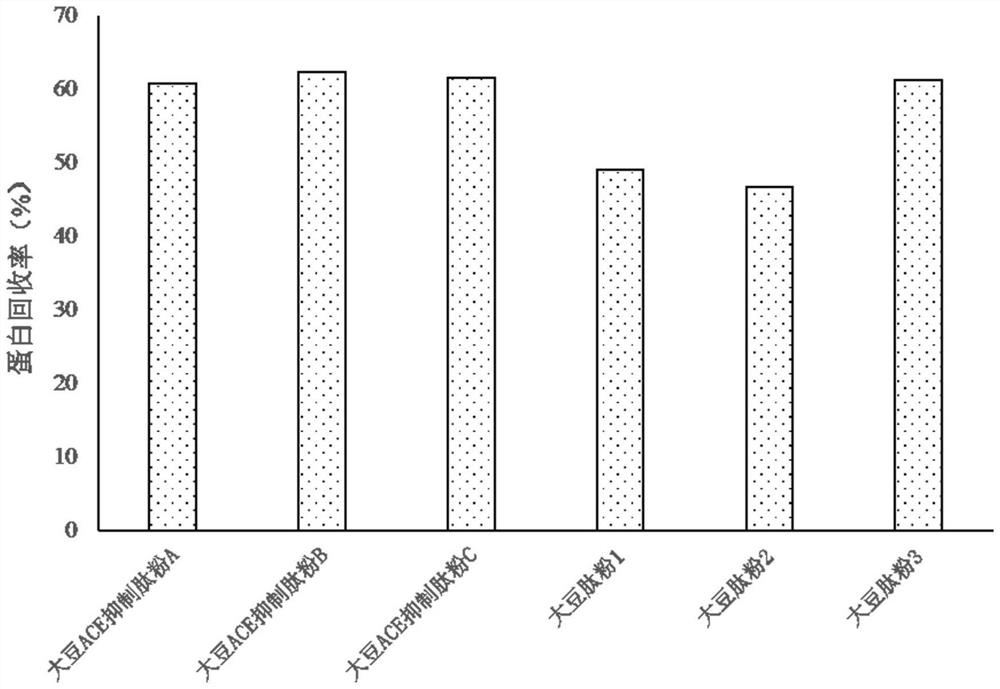

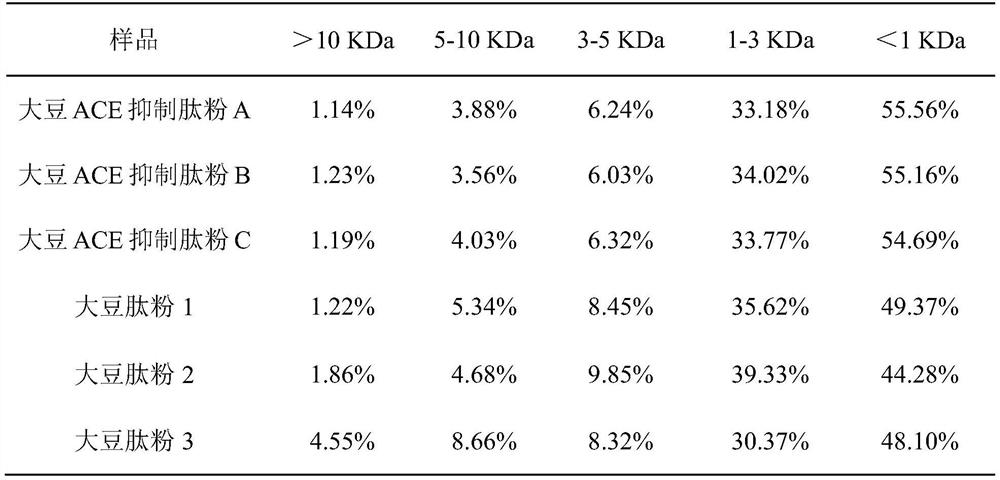

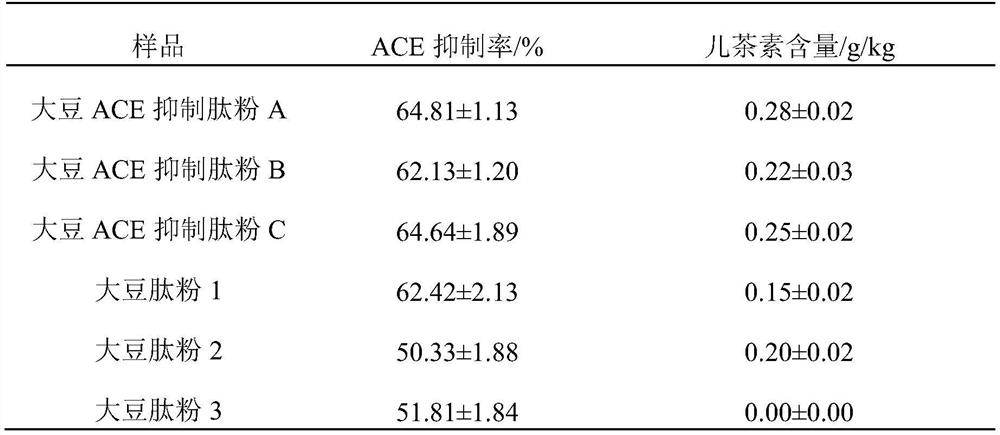

A technology for inhibiting peptides and soybeans, applied in the field of soybean ACE inhibitory peptides and their preparation, can solve the problems of poor clarity of soybean peptides, influence of soybean protein on enzymolysis efficiency, low ACE inhibitory activity, etc., so as to facilitate contact probability and reduce production costs. , the effect of reducing the rate of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of soybean ACE inhibitory peptide, comprising the following steps:

[0052] (1) Take 100kg soybean protein isolate and 300kg alkaline solution (pH=10.0) and mix them with high speed stirring (1000r / min), and then obtain soybean protein slurry by colloid grinding.

[0053] (2) Raise the temperature of the soybean protein slurry to 90°C and keep it warm for 1.5 hours, then lower the temperature to 58°C, add 2kg of alkaline protease (Novozym 37071) from Novozymes, keep it at 58°C for 12 hours, and then enzymatically hydrolyze Adjust the pH of the system to 6.0, then add 0.5 kg of neutral protease (Neutrase 1.5MG) from Novozymes to continue the enzymatic hydrolysis for 7 hours; after the enzymatic hydrolysis, raise the temperature to 95°C and keep it warm for 15 minutes to inactivate the enzyme, and then separate it in a centrifuge The supernatant is soybean enzyme hydrolyzate.

[0054] (3) Measure the amount of solid matter in the soybean enzymolysis ...

Embodiment 2

[0059] A preparation method of soybean ACE inhibitory peptide, comprising the following steps:

[0060] (1) Take 100kg of soybean protein isolate and 500kg of alkaline solution (pH=9.5) and mix them with high-speed stirring (800r / min), and then obtain soybean protein slurry through colloidal grinding.

[0061] (2) Raise the temperature of the soybean protein slurry to 95°C and keep it warm for 1.0 hour, then lower the temperature to 62°C, add 1.2kg of Danisco food-grade alkaline protease (FoodPro Alkaline Protease), keep it at 62°C for 14 hours, and then add the enzyme Adjust the pH of the hydrolysis system to 6.5, and then add 0.8kg of Danisco’s neutral protease (Alphalase NP) to continue the enzymolysis for 5 hours; The clear liquid is soybean enzymatic hydrolyzate.

[0062] (3) Measure the amount of solid matter in the soybean enzymatic hydrolysis solution, add 0.6% tea polyphenols and 10.0% diatomaceous earth, then heat up to 70°C and stir for 30 minutes; then pass throug...

Embodiment 3

[0067] A preparation method of soybean ACE inhibitory peptide, comprising the following steps:

[0068] (1) Take 100kg of soybean protein isolate and 400kg of alkaline solution (pH=9.8) and mix them with high-speed stirring (900r / min), and then obtain soybean protein slurry through colloidal grinding.

[0069] (2) Raise the temperature of the soybean protein slurry to 92°C and keep it warm for 1.3 hours, then lower the temperature to 60°C, add 1.6kg of alkaline protease (Novozym 37071) from Novozymes, keep it at 60°C for 13 hours, and then add the enzyme Adjust the pH of the hydrolysis system to 6.3, then add 0.6 kg of neutral protease (Neutrase 1.5MG) from Novozymes to continue the enzymolysis for 6 hours; after the enzymolysis, raise the temperature to 90°C and keep it for 20 minutes to inactivate the enzyme, and then separate it in a centrifuge to obtain The supernatant was soybean enzymatic hydrolyzate.

[0070] (3) Measure the amount of solid matter in the soybean enzymo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com