Transition metal nitrogen-doped phosphide catalyst as well as preparation method and application thereof

A transition metal and catalyst technology, applied in the field of transition metal nitrogen-doped phosphide catalysts and their preparation, can solve the problems of inability to make full use of nitrogen gas for simultaneous nitriding, increase active sites and electron transport capabilities, and improve electrocatalytic performance , Increase the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

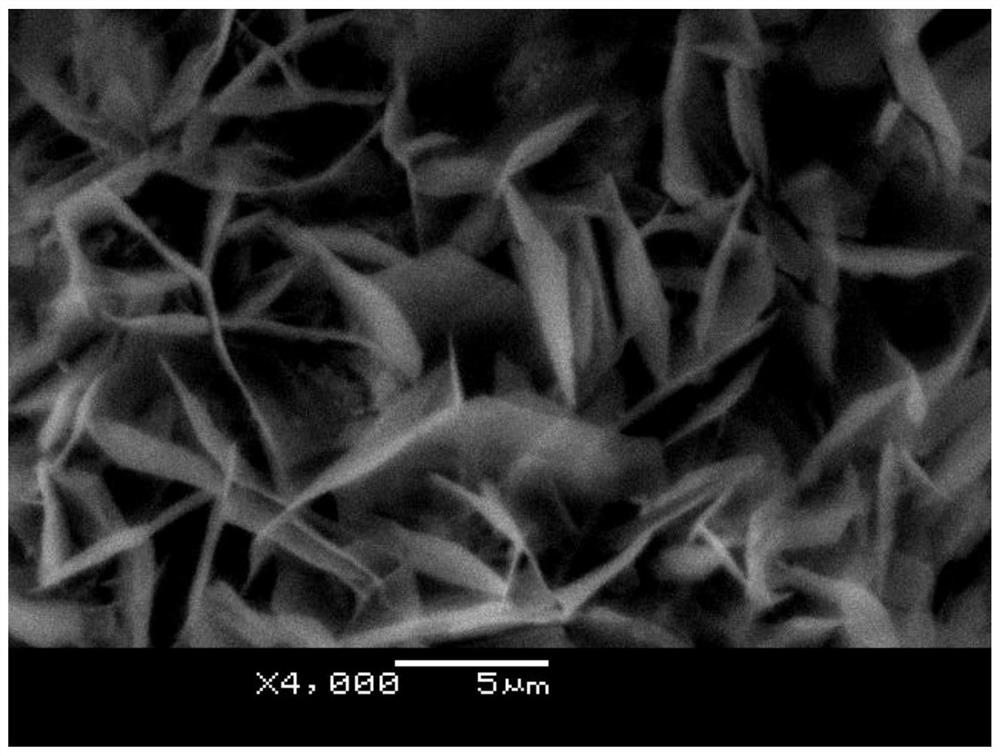

[0037] Step 1: First, ultrasonically clean the foamed nickel-cobalt iron with a size of 1cm×1cm×1cm with acetone, then wash with ethanol and deionized water three times respectively, put it in a vacuum drying oven and dry it to obtain the pretreated Transition metal foam.

[0038] Step 2: Transfer the treated metal foam together with 35 mL of deionized water to a Teflon autoclave for hydrothermal reaction. The hydrothermal temperature is 200° C. and the hydrothermal time is 24 hours. After the reaction, the samples were taken out, washed three times with ethanol and deionized water, and then dried in a vacuum oven.

[0039] Step 3, along the direction of the airflow, place the dried sample on a porcelain boat and place it downstream of the tube furnace. Then weigh 0.2g of red phosphorus and spread it on the bottom of another porcelain boat, and place it upstream of the tube furnace. Set the temperature rise control program.

[0040] Step 4, enter N 2 Gas 10min, gas flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com