Environment-friendly building cement and preparation method thereof

A construction cement and environmental protection technology, applied in the direction of cement production, etc., to achieve the effects of easy availability of raw materials, not easy to crack and hollow, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

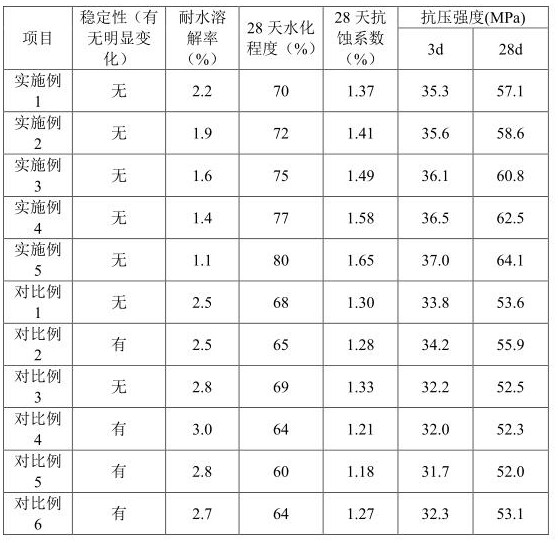

Examples

Embodiment 1

[0029] Embodiment 1 provides an environmentally friendly building cement, which is characterized in that it is made of the following raw materials in parts by weight: 40 parts of cement clinker, 5 parts of modified dry sludge, 6 parts of desulfurization ash, and 3 parts of waste polyester fiber , 10 parts of calcite powder, 1 part of rare earth metal organic framework, 1 part of N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid modified epoxy-terminated hyperbranched poly(amine-ester).

[0030]The preparation method of the modified dried sludge comprises the following steps: dispersing the dried sludge in an organic solvent, and then adding N,N-bis(2-hydroxyethyl)-N,N-bis (Trimethoxysilylpropyl) ethylenediamine was stirred and reacted at 50°C for 3 hours, and then the solvent was removed by rotary evaporation to obtain modified dried sludge; the dried sludge, organic solvent, N,N-bis The mass ratio of (2-hydroxyethyl)-N,N-bis(trimethoxysilylpropyl)ethylenediamine is 1:3:0...

Embodiment 2

[0034] Embodiment 2 provides an environmentally friendly building cement, which is characterized in that it is made of the following raw materials in parts by weight: 45 parts of cement clinker, 6 parts of modified dry sludge, 7 parts of desulfurization ash, and 3.5 parts of waste polyester fiber , 11 parts of calcite powder, 1.2 parts of rare earth metal organic framework, 2 parts of N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid modified epoxy-terminated hyperbranched poly(amine-ester).

[0035] The preparation method of the modified dried sludge comprises the following steps: dispersing the dried sludge in an organic solvent, and then adding N,N-bis(2-hydroxyethyl)-N,N-bis (Trimethoxysilylpropyl) ethylenediamine was stirred and reacted at 55°C for 3.5 hours, and then the solvent was removed by rotary evaporation to obtain modified dry sludge; the dry sludge, organic solvent, N,N-bis The mass ratio of (2-hydroxyethyl)-N,N-bis(trimethoxysilylpropyl)ethylenediamine is ...

Embodiment 3

[0039] Embodiment 3 provides an environmentally friendly building cement, which is characterized in that it is made of the following raw materials in parts by weight: 50 parts of cement clinker, 7 parts of modified dry sludge, 8 parts of desulfurization ash, and 4 parts of waste polyester fiber , 13 parts of calcite powder, 1.5 parts of rare earth metal organic framework, 3.5 parts of N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid modified epoxy-terminated hyperbranched poly(amine-ester).

[0040] The preparation method of the modified dried sludge comprises the following steps: dispersing the dried sludge in an organic solvent, and then adding N,N-bis(2-hydroxyethyl)-N,N-bis (Trimethoxysilylpropyl) ethylenediamine was stirred and reacted at 60°C for 4 hours, and then the solvent was removed by rotary evaporation to obtain a modified dry sludge; the dry sludge, organic solvent, N,N-bis The mass ratio of (2-hydroxyethyl)-N,N-bis(trimethoxysilylpropyl)ethylenediamine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com