A kind of preparation method of nanometer neodymium oxide coated zirconia powder

A technology of zirconia powder and neodymium oxide, which is applied in the field of preparation of nano-neodymium oxide-coated zirconia powder, can solve the problems of optical glass scratches and Araby phenomenon, and achieve scratches, uniform particle size and controllable, The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

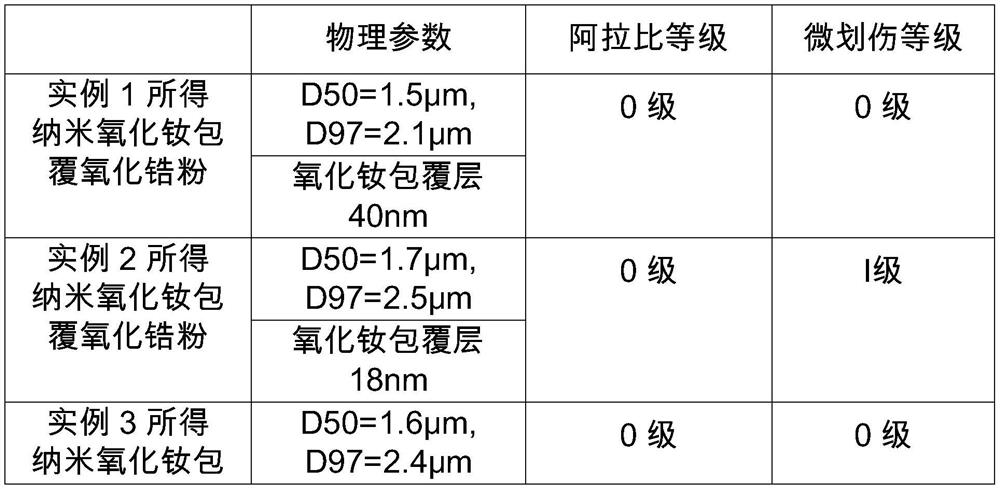

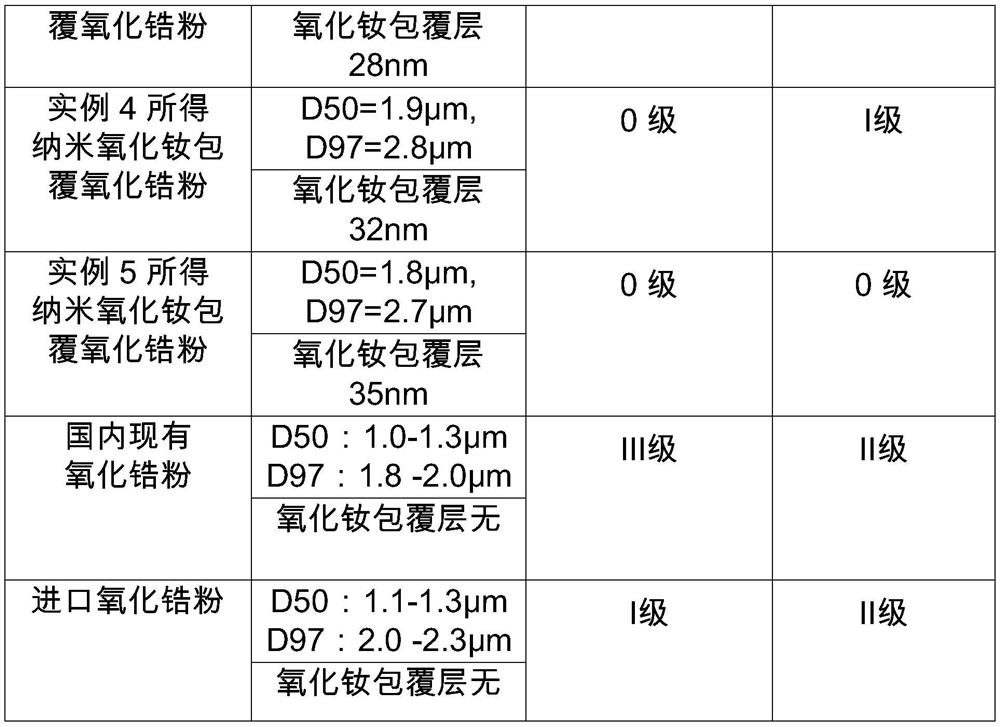

Examples

Embodiment 1

[0034] The preparation method of nano neodymium oxide coated zirconia powder of the present embodiment, its preparation steps are as follows:

[0035] (1) Preparation of composite suspension: first heat deionized water to 75°C, then add sodium polyacrylate with a molecular weight of 10,000, then add BYK-420, and finally add Tween 80, stir, dissolve, clarify, and then cool to make each group In the solution, the mass ratio is 0.1% sodium polyacrylate (molecular weight: 10000), 0.2% BYK-420, 0.3% Tween 80, to obtain a composite suspension agent, and set aside;

[0036] (2) Preparation of neodymium chloride and praseodymium chloride solution: Weigh 200kg of deionized water and add it to an oil bath reactor, then add neodymium chloride and praseodymium chloride with a molar ratio of 99:1 into the deionized water to prepare Neodymium chloride and praseodymium chloride molar concentration is the neodymium chloride and praseodymium chloride solution of 0.3mol / L, standby;

[0037] (3...

Embodiment 2

[0044] The preparation method of nano neodymium oxide coated zirconia powder of the present embodiment, its preparation steps are as follows:

[0045] (1) Preparation of composite suspending agent: first heat deionized water to 80°C, then add sodium polyacrylate with a molecular weight of 10,000, then add BYK-420, and finally add Tween 80, stir, dissolve, clarify, and then cool to make each group The mass ratio in the solution is 0.3% sodium polyacrylate (molecular weight: 10,000), 0.1% BYK-420, 0.1% Tween 80, to obtain a composite suspension agent, and set aside;

[0046](2) Preparation of neodymium chloride and praseodymium chloride solution: Weigh 250kg of deionized water and add it to an oil bath reactor, then add neodymium chloride and praseodymium chloride with a molar ratio of 99:1 into the deionized water to prepare Become neodymium chloride and praseodymium chloride molar concentration and be the neodymium chloride and praseodymium chloride solution of 0.4mol / L, stand...

Embodiment 3

[0054] The preparation method of nano neodymium oxide coated zirconia powder of the present embodiment, its preparation steps are as follows:

[0055] (1) Preparation of composite suspending agent: first heat deionized water to 85°C, then add sodium polyacrylate with a molecular weight of 10,000, then add BYK-420, and finally add Tween 80, stir, dissolve, clarify, and then cool to make each group In the solution, the mass ratio is 0.2% sodium polyacrylate (molecular weight: 10000), 0.3% BYK-420, 0.2% Tween 80, to obtain a composite suspending agent for future use;

[0056] (2) Preparation of neodymium chloride and praseodymium chloride solution: Weigh 300kg of deionized water and add it to the oil bath reactor, then add neodymium chloride and praseodymium chloride with a molar ratio of 99:1 into the deionized water to prepare Become neodymium chloride and praseodymium chloride molar concentration and be the neodymium chloride and praseodymium chloride solution of 1.0mol / L, sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com