Cigarette tipping phase-change material for cigarette tipping paper as well as preparation method and application of phase-change material

A technology for cigarette tipping paper and phase change material, which is applied in the direction of adding process of wrapping paper, wrapping paper and pulp raw materials, etc., can solve the problems of high price, increased cost and high film forming temperature, and achieves high production efficiency and easy operation. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

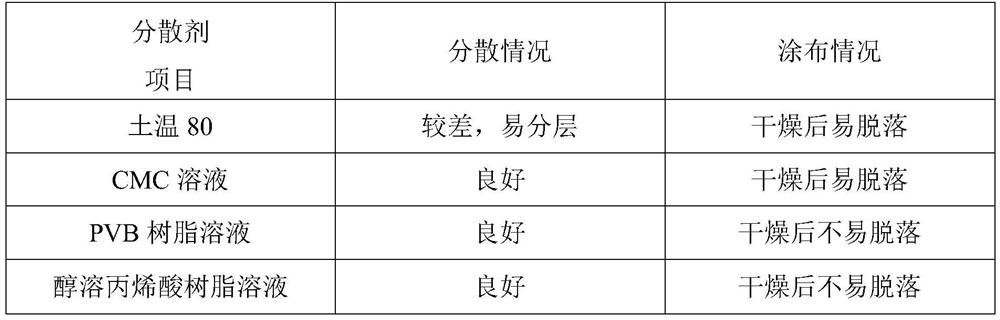

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of phase change material for cigarette tipping paper:

[0044] ① Take 80 parts by weight of absolute ethanol, then add 20 parts by weight of alcohol-soluble acrylic resin (solid, Guangdong Huari Technology Co., Ltd.) in batches, stir continuously and heat until completely dissolved, and the stirring speed is 200-300r / min, the heating temperature is 40°C, to obtain a concentration of 20wt% alcohol-soluble acrylic resin solution;

[0045] ② Take 75 parts by weight of alcohol-soluble acrylic resin solution, add 25 parts by weight of ethylene-methyl methacrylate copolymer (150 mesh, referred to as EMMA) (Zhangjiagang Yarui Chemical Co., Ltd.), fully stir to obtain a uniform and stable smoke Cigarette phase change material with tipping paper.

[0046] (2) The use of phase change materials in cigarette tipping paper:

[0047] On the gravure printing machine, the cigarette phase-change material for cigarette tipping paper described in (1) is coated on the ba...

Embodiment 2

[0049] (1) Preparation of phase change material for cigarette tipping paper:

[0050] ① Take 80 parts by weight of absolute ethanol, then add 20 parts by weight of alcohol-soluble acrylic resin in batches, stir continuously and heat until completely dissolved, the stirring speed is 200-300r / min, and the heating temperature is 40°C to obtain the concentration Be 20wt% alcohol-soluble acrylic resin solution;

[0051] ② Take 70 parts by weight of an alcohol-soluble acrylic resin solution, add 30 parts by weight of ethylene-methyl methacrylate copolymer (150 mesh), and fully stir to obtain a uniform and stable cigarette tipping paper cigarette phase change material.

[0052] (2) The use of phase change materials in cigarette tipping paper:

[0053] On the gravure printing machine, the cigarette phase-change material for cigarette tipping paper described in (1) is coated on the back side of the cigarette tipping paper, and the parameter settings during gravure printing are respect...

Embodiment 3

[0055] (1) Preparation of phase change material for cigarette tipping paper:

[0056] ① Take 70 parts by weight of absolute ethanol, then add 30 parts by weight of alcohol-soluble acrylic resin in batches, stir continuously and heat until completely dissolved, the stirring speed is 200-300r / min, and the heating temperature is 40°C to obtain the concentration Be 30wt% alcohol-soluble acrylic resin solution;

[0057] ② Take 90 parts by weight of alcohol-soluble acrylic resin solution, add 10 parts by weight of ethylene-methyl methacrylate copolymer (150 mesh), and fully stir to obtain a uniform and stable cigarette tipping paper cigarette phase change material.

[0058] (2) Use of cigarette phase change material in cigarette tipping paper: the method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com