Dodecyl amine modified carbon nanotube demulsifier as well as preparation method and application thereof

A technology of carbon nanotubes and dodecylamine, applied in chemical instruments and methods, chemical dehydration/demulsification, carbon compounds, etc., can solve the problems of complex preparation process of demulsifier and poor demulsification effect of demulsifier, etc. Achieve the effect of low cost, cost saving and explosion reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

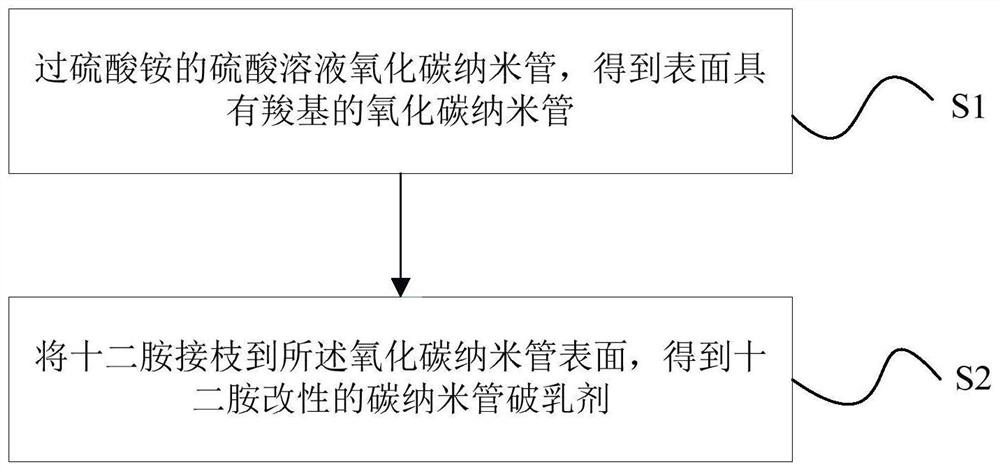

[0019] figure 1 Prepare the process flow sheet of the carbon nanotube demulsifier modified by dodecylamine for the present invention, as figure 1 Shown, the embodiment of the present invention provides a kind of preparation method of the carbon nanotube demulsifier modified by dodecylamine, and this preparation method comprises the steps:

[0020] (1) sulfuric acid solution of ammonium persulfate oxidizes carbon nanotubes to obtain oxidized carbon nanotubes with carboxyl groups on the surface;

[0021] (2) Grafting dodecylamine onto the surface of oxidized carbon nanotubes to obtain a dodecylamine-modified carbon nanotube demulsifier.

[0022] The present invention firstly prepares oxidized carbon nanotubes with carboxyl groups on the surface, then grafts dodecylamine onto the surface of oxidized carbon nanotubes, and reacts alkylamines with long hydrophobic chains with carboxyl groups on oxidized carbon nanotubes to obtain broken The emulsion can be distributed faster at th...

Embodiment 1

[0045] Embodiment 1 of the present invention provides a carbon nanotube demulsifier modified by dodecylamine, and the carbon nanotube demulsifier modified by dodecylamine is prepared by the following method:

[0046] (1) Dissolve ammonium persulfate in 1mol / L H 2 SO 4 In the solution, the concentration of ammonium persulfate is 2 mol / L to obtain a mixed solution I; 1 weight part of carbon nanotubes is added to 20 parts by weight of the above mixed solution I, and reacted at 70° C. for 10 h under stirring. After the reaction is completed, the oxidized carbon nanotubes are obtained by centrifugal separation, washing with distilled water and vacuum drying;

[0047] (2) Mix the above-mentioned oxidized carbon nanotubes, dodecylamine and dicyclohexylcarbodiimide according to a weight ratio of 1:100:20 to obtain mixture II; transfer mixture II to an oil bath, and React at 120° C. for 10 h. After the reaction is completed, the reaction product is washed several times with ethanol, ...

Embodiment 2

[0050] Embodiment 2 of the present invention provides a carbon nanotube demulsifier modified by dodecylamine, and the carbon nanotube demulsifier modified by dodecylamine is prepared by the following method:

[0051] (1) Dissolve ammonium persulfate in 1mol / L H 2 SO 4 In the solution, the concentration of ammonium persulfate is 1 mol / L to obtain a mixed solution I; 1 weight part of carbon nanotubes is added to 20 parts by weight of the above mixed solution I, and reacted at 70° C. for 8 hours under stirring, After the reaction is completed, the oxidized carbon nanotubes are obtained by centrifugal separation, washing with distilled water and vacuum drying;

[0052] (2) Mix the above-mentioned oxidized carbon nanotubes, dodecylamine and dicyclohexylcarbodiimide according to a weight ratio of 1:100:20 to obtain mixture II; transfer mixture II to an oil bath, and React at 120° C. for 10 h. After the reaction is completed, the reaction product is washed several times with ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com