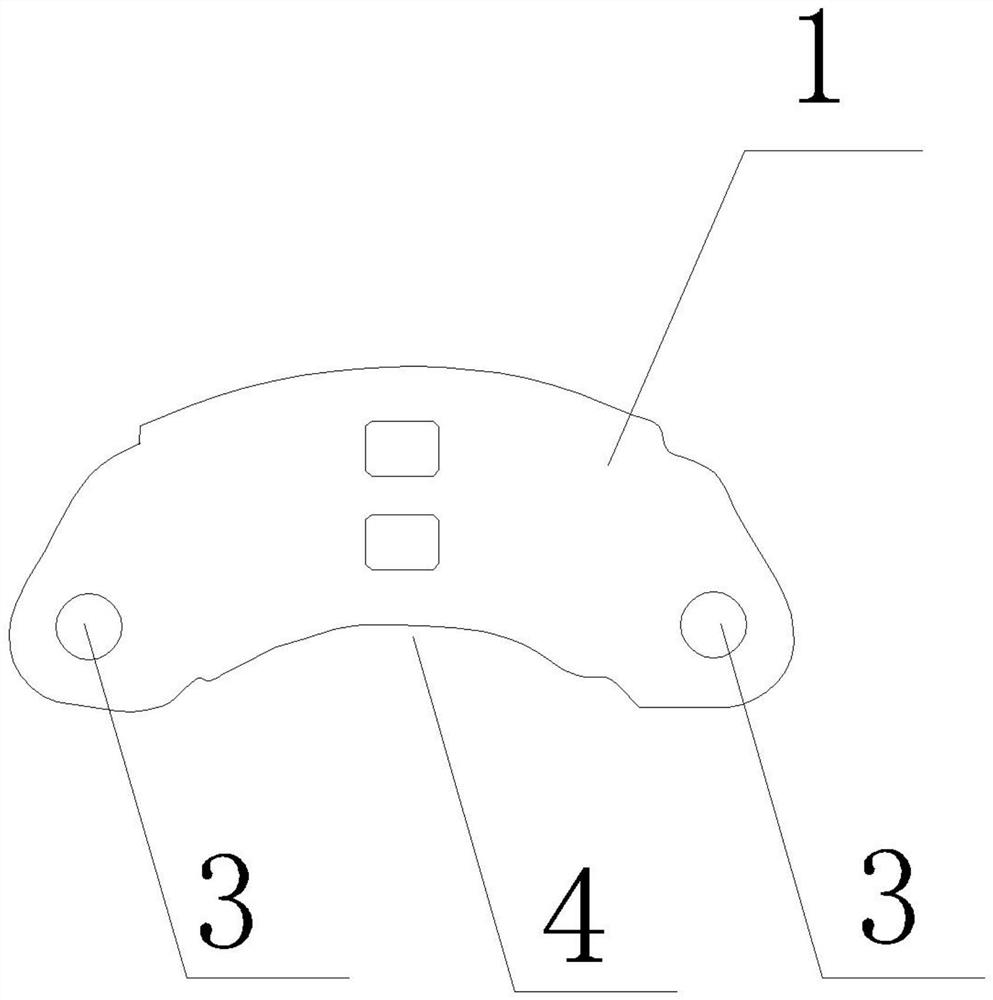

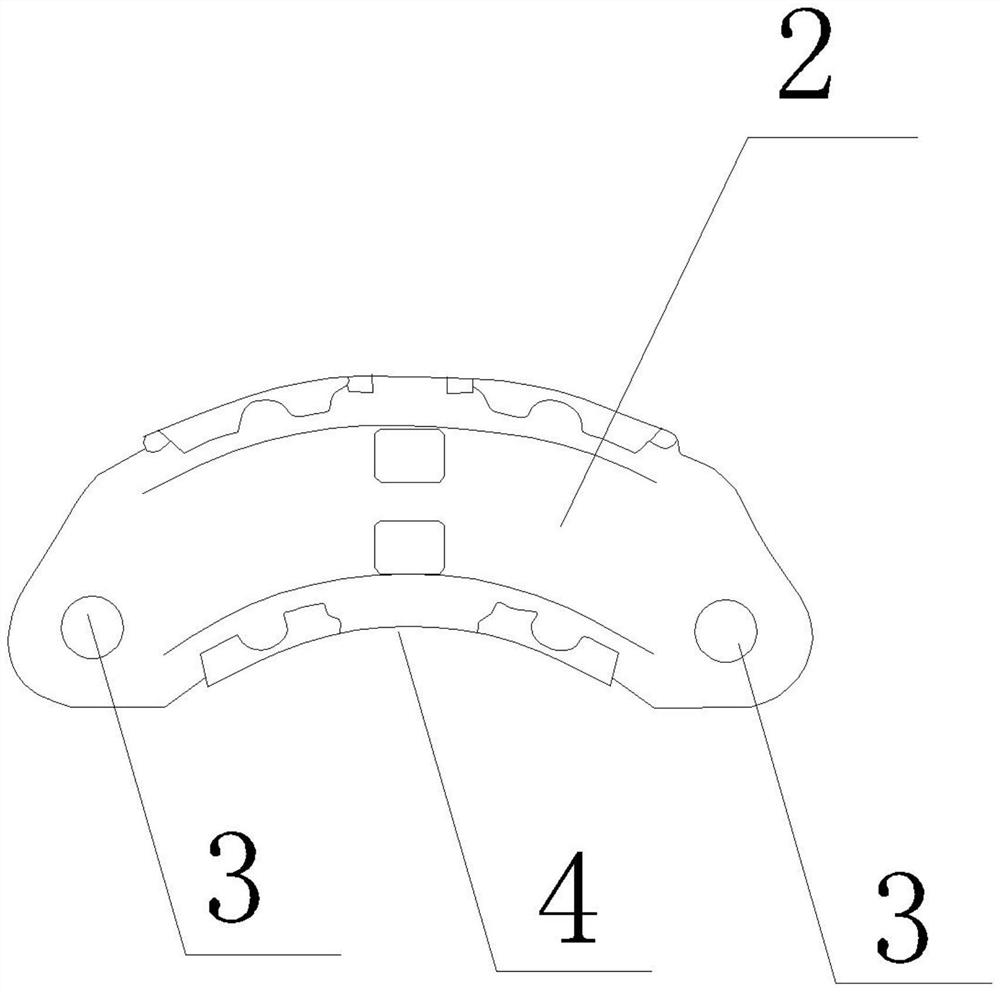

A production process of high-strength and high-toughness high-speed rail brake pads

A production process, high toughness technology, applied in the field of casting process, can solve the problems of unqualified material, poor toughness, unstable process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 1. Melting process

[0076] 1. Material selection

[0077] (1) The pig iron adopts pig iron Q10 for high-quality nodular cast iron;

[0078] The specific requirements for pig iron Q10 for high-quality ductile iron are as follows:

[0079] One class one group;

[0080] C>3.4%, Si0.5-1%, Mn<0.1%, S≤0.03%, P≤0.035%, Ti≤0.03%;

[0081] The sum of impurity elements Cr, V, Pb, Bi, As, B, Al, Mo, Sb≤0.085%;

[0082] Surface quality: clean surface, no slag, no sand, no rust, uniform lumpiness;

[0083] Fix the pig iron supplier, and do not change the pig iron supplier at will after the production is stable.

[0084] Among them, the requirements for trace elements that hinder graphitization are strictly limited as follows: S≤0.03%, P≤0.035%, Ti≤0.03%, V<0.0007%, Al<0.005%, B<0.0005%, Sb<0.0005%.

[0085] (2) Scrap steel is made of high-quality carbon structural steel;

[0086] The requirements for the high-quality carbon structural steel are as follows:

[0087] Chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com