Alkaline etching solution and alkaline etching solution in-situ electrolysis copper extraction recycling device and method

An etching solution and etching waste solution technology, applied in the direction of electrolysis process, electrolysis components, and process efficiency improvement, can solve the problems of difficult system safe operation, unqualified line accuracy, slow stability and speed, etc. Anti-side corrosion ability, not easy to precipitate crystallization, stable precipitation crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

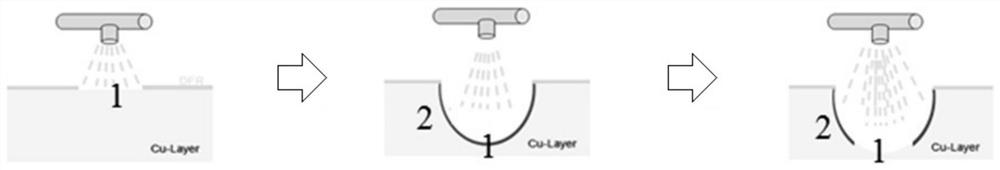

Problems solved by technology

Method used

Image

Examples

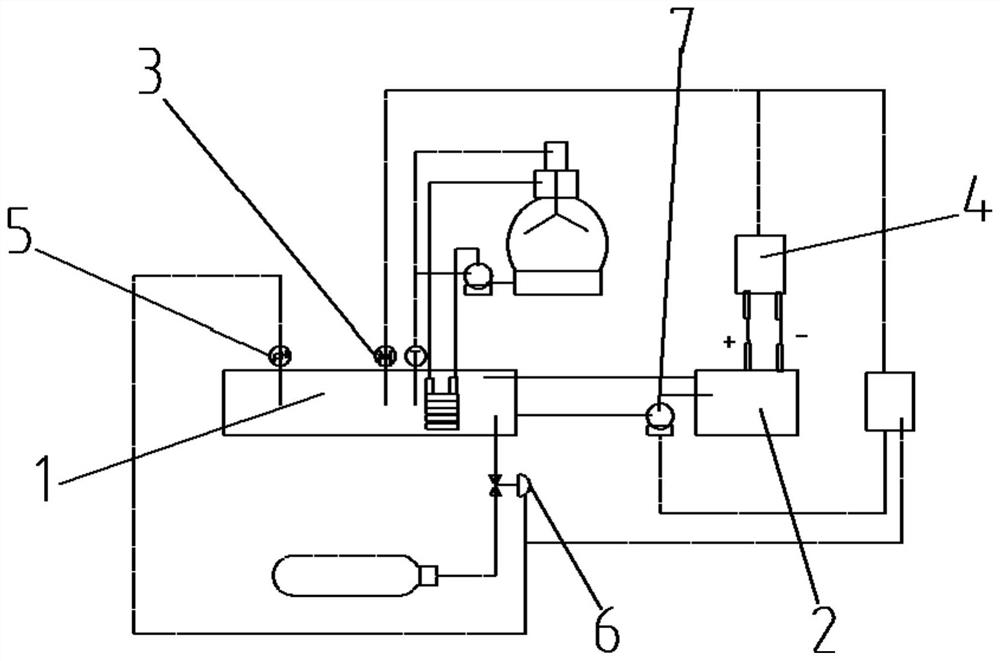

specific Embodiment example 1

[0108] A pcb Jiangsu mentioned alkaline etching and recycling use of copper, using online situ electrolytic copper extraction cycle scheme. Was determined to 120g / L ammonium bicarbonate, 10g / L of ammonium nitrate, 10g / L ammonium phosphate, 10g / L of ammonium oxalate, 100g / L of ammonium chloride, 100g / L of ammonia, 180g / L of copper ions, 5g / L alkenyl propyl thiourea, 465g / L of water, running board etching speed of 5 m / min, the amount of copper etching 5kg / h, the precision circuit board 50um. Situ etching and electrolytic copper extraction equipment lines are directly connected, by the circulating pump and the electrolytic etching machines extract the copper etching solution mixed uniformly apparatus, the electrolytic current rectifier 600A (rectifier operating range 0-1000A), copper extraction rate of 5kg / hours, real-time monitoring of copper ions to adjust the rectifier current magnitude changes. After 5 days 24 hours electrolytic etching production and recy...

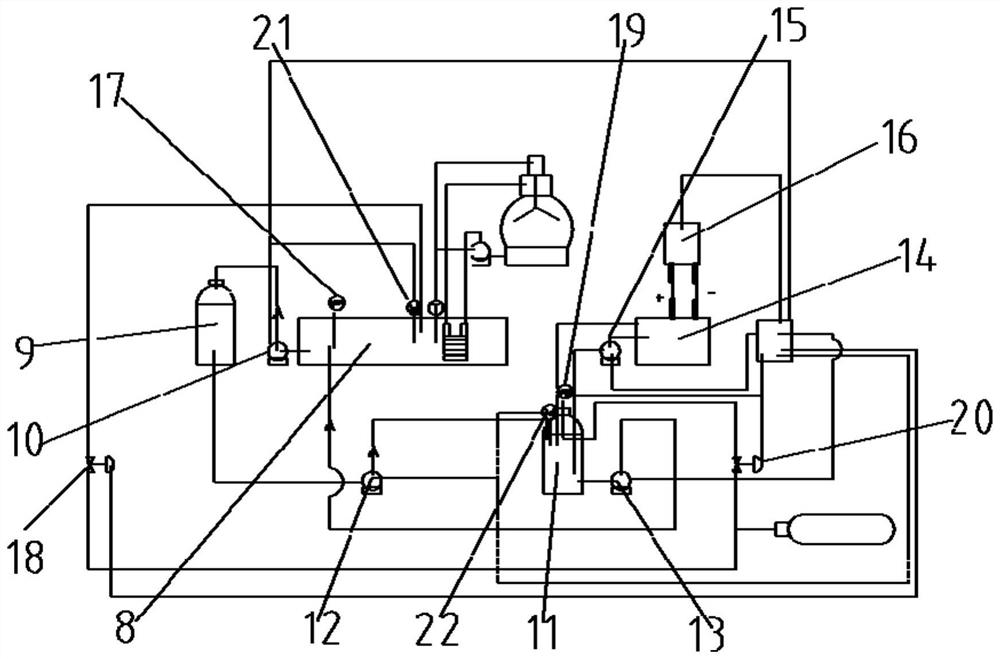

specific Embodiment example 2

[0110] Zhejiang a pcb mentioned alkaline etching and recycling use of copper, using off-situ regeneration cycle electrolytic solution. Alkaline etching waste liquor was determined to 125g / L ammonium bicarbonate, 15g / L ammonium nitrate, 15g / L ammonium phosphate, 15g / L of ammonium oxalate, 110g / L of ammonium chloride, 100g / L of ammonia, 200g / L of copper ions, 5g / L allyl thiourea, 415g / L of water, the etching speed running board 4.8 m / min, the amount of copper etching 5kg / h, the precision circuit board 75um. Situ etching and electrolytic copper extraction device regeneration cycles the tub was connected by a circulation pump mixing etcher and etching regeneration solution was uniformly barrel etching, the Cu ion concentration control 50g / L, the electrolysis current rectifier 350A (rectifier work range 0-1000A), copper extraction rate of 3.5kg / hr, real-time monitoring tub regeneration fluid concentration of copper ions automatically supplemented alkali etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com