Two-medium circulating dyeing method with high dye-uptake and color fastness

A dyeing method and dye uptake technology, applied in the field of fabric dyeing, can solve the problems of low color depth, difficult recycling and high energy consumption, and achieve the effect of high color depth and full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

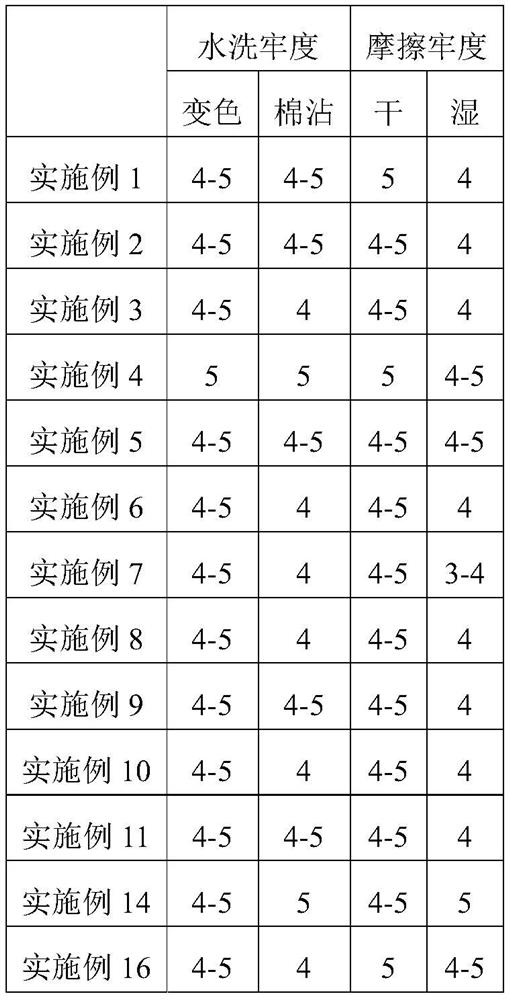

Examples

Embodiment 1

[0023] A double-medium cycle dyeing method with high dye uptake and color fastness, said method comprising the steps of:

[0024] Preparation of pad dyeing solution: Add active green blue B-BGFN and potassium hydroxide to the mixed solvent, fully dissolve at 30°C, wherein: the concentration of active green blue B-BGFN is 25g / L, and the concentration of potassium hydroxide is 5g / L, the mixed solvent is a mixture of dimethyl sulfoxide and ethanol at a volume ratio of 1:1;

[0025] Pure cotton fiber pad dyeing: pre-swell the fiber in the pad dyeing solution at 30°C for 2 minutes, and then pad the pre-swelled fiber at 0.1 MPa;

[0026] Pure cotton fiber dyeing: put the padded fiber into a supercritical carbon dioxide dyeing kettle, dye the padded fiber at 90°C and 20MPa for 60 minutes, and take the fiber out of the supercritical carbon dioxide dyeing kettle after releasing the pressure;

[0027] Cleaning of pure cotton fibers: Put the dyed fibers into the cleaning tank and wash t...

Embodiment 2

[0032] A double-medium cycle dyeing method with high dye uptake and color fastness, said method comprising the steps of:

[0033] Preparation of pad dyeing solution: Add active golden BPF, urea, and potassium hydroxide to the mixed solvent, fully dissolve at 25°C, wherein: the concentration of active golden BPF is 10g / L, the concentration of urea is 5g / L, The concentration of potassium is 5g / L, and the mixed solvent is a mixture of dimethyl sulfoxide and ethanol at a volume ratio of 1:5;

[0034] Bamboo fiber pad dyeing: pre-swell the fiber in the pad dyeing solution at 25°C for 2 minutes, and then pad the pre-swelled fiber at 0.2 MPa;

[0035] Bamboo fiber dyeing: put the padded fiber into a supercritical carbon dioxide dyeing kettle, dye the padded fiber at 95°C and 24MPa for 60 minutes, and take the fiber out of the supercritical carbon dioxide dyeing kettle after releasing the pressure;

[0036] Bamboo fiber cleaning: put the dyed fiber into the cleaning tank and wash it ...

Embodiment 3

[0041] A double-medium cycle dyeing method with high dye uptake and color fastness, said method comprising the steps of:

[0042] Prepare pad dyeing solution: add urea and sodium hydroxide to the mixed solvent, fully dissolve at 40°C, then cool down to 20°C and add Lihua Shiyanhong E-BA to it to fully dissolve, of which: Lihuashiyanhong E- The concentration of BA is 5g / L, the concentration of urea is 60g / L, the concentration of sodium hydroxide is 5g / L, and the mixed solvent is dimethyl sulfoxide, ethylene glycol and ethanol in a volume ratio of 2:1:1;

[0043] Pad dyeing of flax fiber: pre-swell the fiber in the pad dyeing solution at 20°C for 3 minutes, and then pad the pre-swelled fiber at 0.5MPa;

[0044] Flax fiber dyeing: put the padded fiber into a supercritical carbon dioxide dyeing kettle, dye the padded fiber at 40°C and 20MPa for 120 minutes, and take the fiber out of the supercritical carbon dioxide dyeing kettle after releasing the pressure;

[0045] Linen fiber cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com