Preparation method of radio frequency chip type multilayer ceramic capacitor

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., can solve the problems of high cost, and achieve the effect of easy oxidation, low price and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

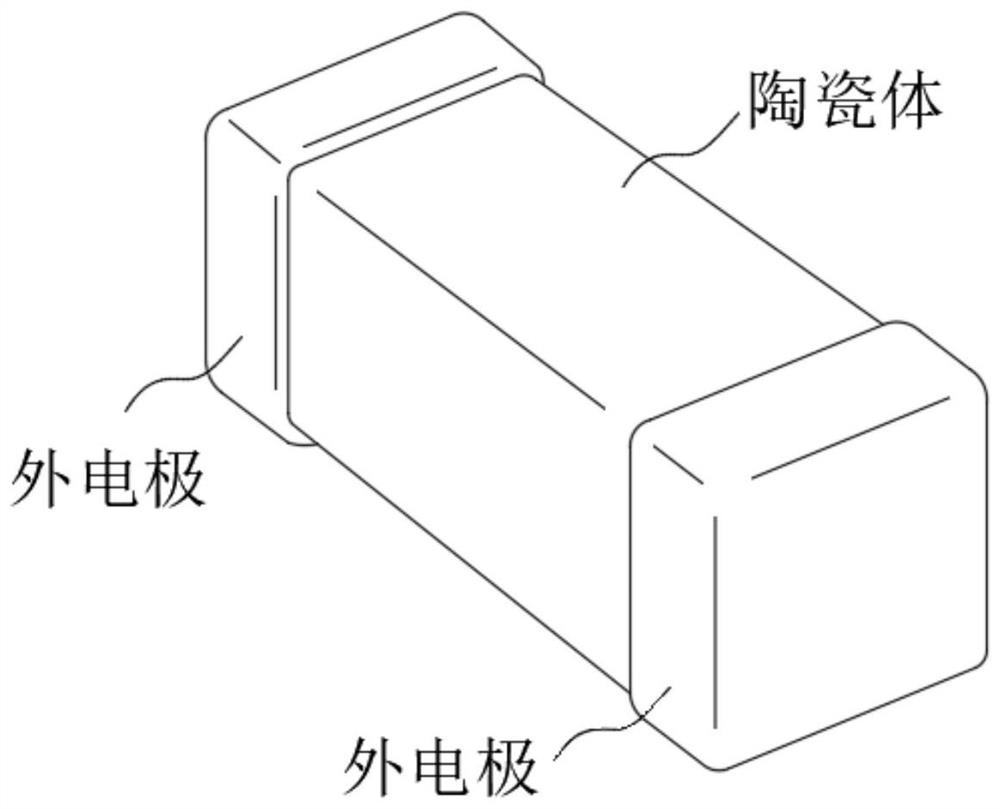

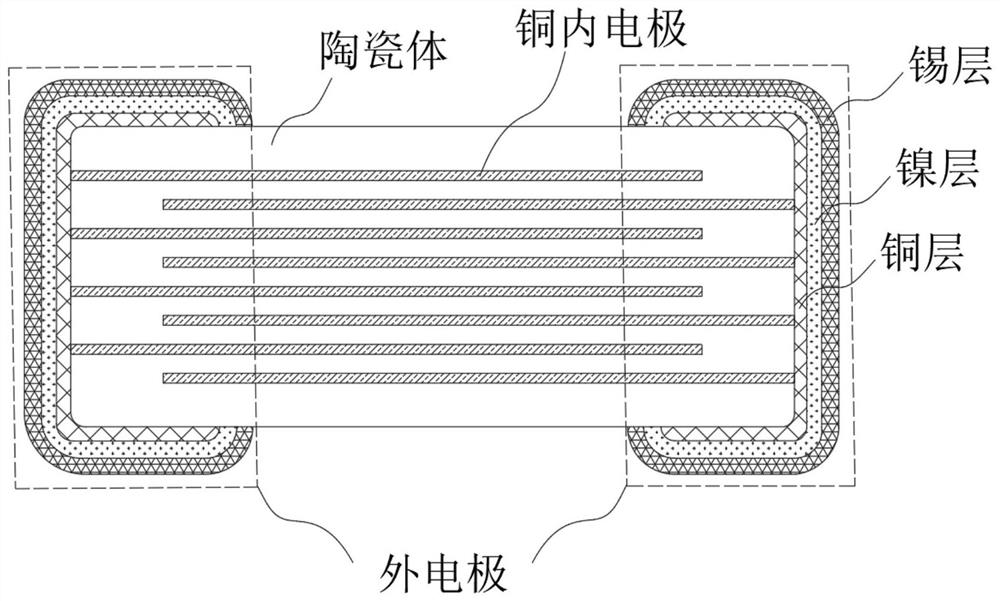

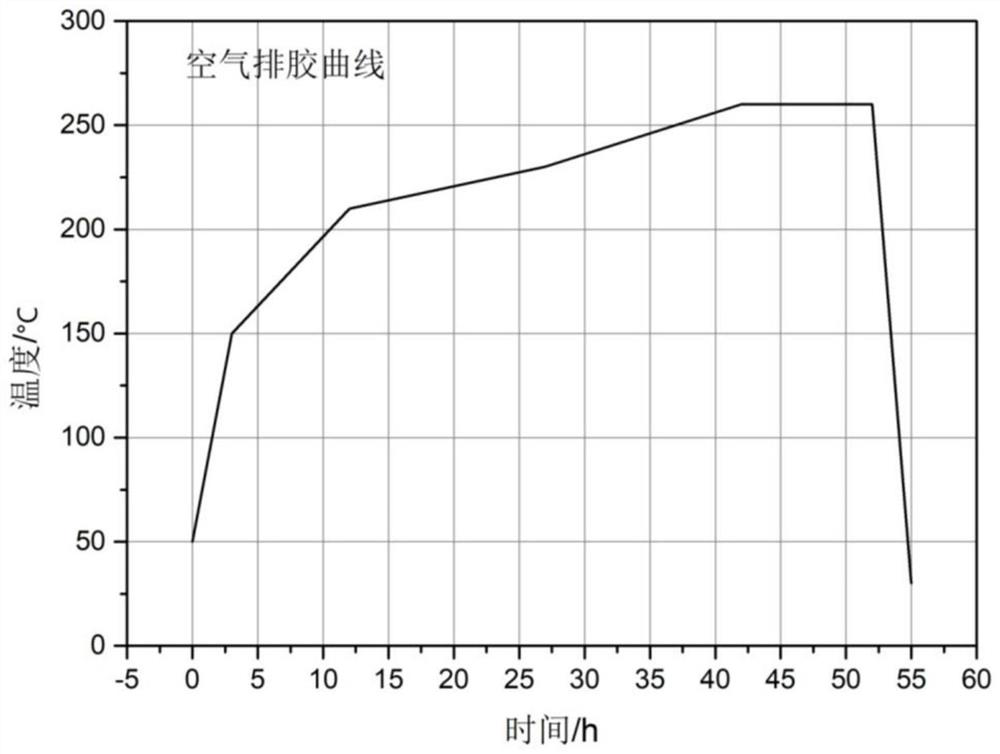

[0050] Such as Figure 1-Figure 2 , Figure 7 As shown, a method for preparing a radio frequency chip multilayer ceramic capacitor includes preparing porcelain slurry, casting dielectric diaphragm, printing copper electrodes, alternating dislocation lamination, lamination, cutting lamination, debinding, firing, pouring Angle, capping, burning end and electroplating preparation process, specifically include the following steps:

[0051] S1. Prepare a high-frequency ceramic slurry, and tape-cast the high-frequency ceramic slurry into a ceramic medium, and the high-frequency ceramic slurry is a Sr-Ca-Zr-Ti series ceramic material;

[0052] S2. Printing copper electrode paste on ceramic medium to prepare a laminate, the solid content of the copper electrode paste is 50% to 60%, wherein copper accounts for 85% of the solid content, and the amount of inorganic substances added accounts for 15%:

[0053] S21, printing the copper electrode paste on the ceramic medium to obtain a membr...

Embodiment 2

[0065] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0066] The debinding method is 450°C nitrogen atmosphere protection debinding, and the nitrogen atmosphere protection debinding is 450°C nitrogen protection debinding, wherein, 220°C-450°C debinding takes 8 hours (220°C to 450°C heating process takes 8 hours ), held at 450°C for 3 hours, and the debinding curve under nitrogen protection is as follows Figure 5 Shown; nitrogen atmosphere protection after debinding laminated body sintering at 750 ℃ for 1.5 hours, the firing curve after nitrogen protection debinding is as follows Image 6 shown.

[0067] In this embodiment, the debinding temperature can be increased to 450°C through nitrogen protection, and the organic matter in the ceramic body is mainly eliminated by pyrolysis, so that the carbon residue in the ceramic is less, but this debinding method requires special atmosphere debinding equipment ; When the laminate is sintered, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com