Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as trench voids, and achieve the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

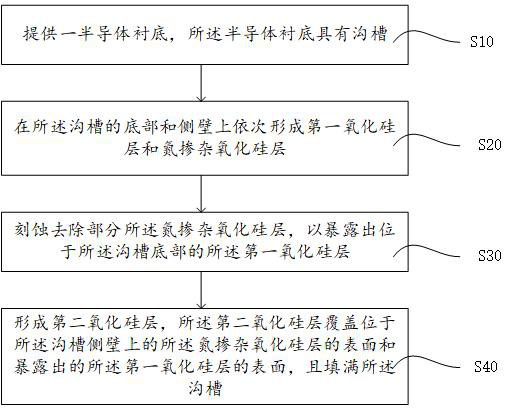

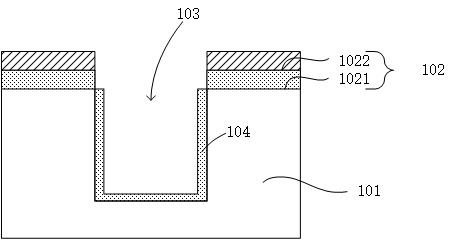

[0036] The following is attached Figure 2-8 The semiconductor structure manufacturing method provided by the embodiment of the present invention is described in detail.

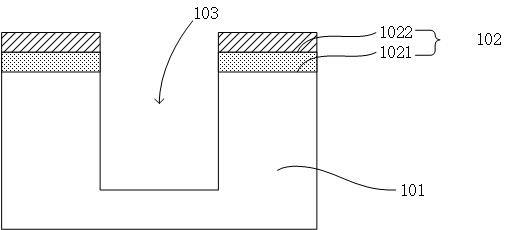

[0037] First, execute step S10, please refer to figure 2 , providing a semiconductor substrate 101 having several trenches 103 . To simplify, figure 2 Only one groove is shown in .

[0038] The semiconductor substrate 101 may be monocrystalline silicon or polycrystalline silicon, or semiconductor materials such as silicon, germanium, silicon germanium, gallium arsenide, or a composite structure such as silicon-on-insulator. Those skilled in the art can select the type of the semiconductor substrate 101 according to the semiconductor devices formed on the semiconductor substrate 101 , so the type of the semiconductor substrate 101 should not limit the protection scope of the present invention.

[0039] In a specific embodiment, the trench 103 serves as an isolation structure to provide isolation for the...

Embodiment 2

[0071] The difference from Embodiment 1 is that in step S20, the nitrogen-doped silicon oxide layer 105 is formed by an NO annealing process, and the NO annealing process is formed by gas NO and SiO in the first silicon oxide layer 104 2 reaction to generate SiO x N y , in this embodiment, the nitrogen-doped silicon oxide layer 105 is SiO x N y .

[0072] In the NO annealing process, the temperature of the annealing treatment can be set according to actual needs. Preferably, in this embodiment, the temperature of the annealing treatment is 800°C-1100°C.

[0073] In the NO annealing process, the time for the annealing treatment can be set according to actual needs. Preferably, in this embodiment, the time for the annealing treatment is less than 70s.

[0074] In the NO annealing process, the pressure of the annealing treatment can be set according to actual needs. Preferably, in this embodiment, the pressure of the annealing treatment is 500 torr-1000 torr.

[0075] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com