Piezoelectric and/or thermoelectric reinforced electrofiltration long-term double-effect filter material and manufacturing method thereof

A manufacturing method and filter material technology, which are applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of low efficiency, high escape rate, and single capture mechanism of fine particles, so as to increase the capture efficiency and reduce the Escape rate, overcoming the effect of easy decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1 Polyester needle felt double-effect filter material

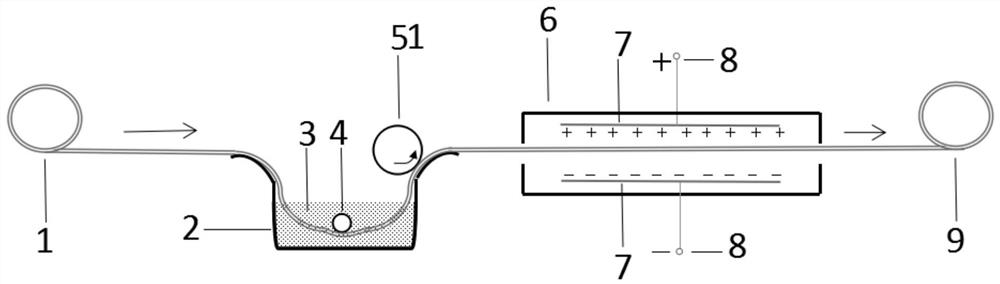

[0074] The specific manufacturing method of polyester needle-punched double-effect filter material can be manufactured by submerged impregnation. The process flow is as follows: figure 1 as shown,

[0075] Take an acrylic emulsion with a solid content of 65%, and add water to it to dilute it so that the solid content is 20%. Add polyvinylidene fluoride (PVDF) material powder with a mass fraction of 15% and a median diameter of 20 μm, stir evenly, and pour it into the solution container 2 as the coating emulsion 3, that is, the tank container.

[0076] Filtrate substrate 1 gets 550 grams per square meter of pure polyester needle-punched felt substrate rolls, dips through the coating emulsion 3 under the gravity pressure bar 4, and squeezes through the extrusion roller 51 to make the coating emulsion 3 into the interior of the filter material, and also squeeze off part of the excess coating emulsion 3.

[...

Embodiment 2

[0079] Embodiment 2 polyphenylene sulfide hydroentangled felt filter material

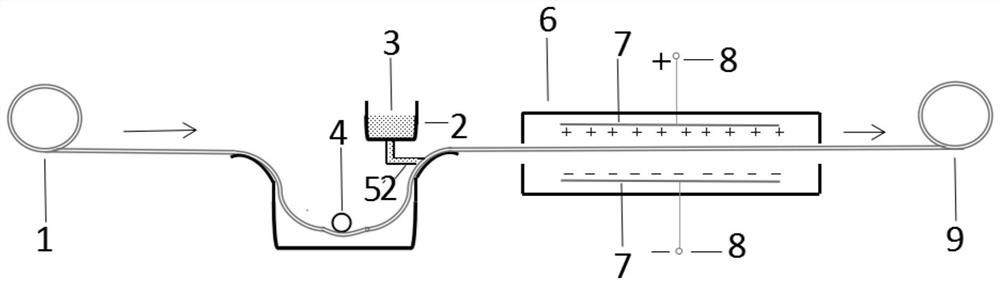

[0080] The specific manufacturing method of polyester needle-punched double-effect filter material can be manufactured by scraper method, and the process flow is as follows: figure 2 Shown:

[0081] Take a polytetrafluoroethylene emulsion with a solid content of 60%, add water to it for dilution, and make the solid content 20%. Add lead zirconate titanate piezoelectric material powder with a mass fraction of 10% and a median diameter of 15 μm, and a CaSe powder with a mass fraction of 10% and a median diameter of 15 μm, stir evenly to form a coating emulsion 3, pour Put it into the tank type container, that is, pour it into the emulsion container 2.

[0082] Get the filtrate substrate 1, that is, the pure polyphenylene sulfide hydroentangled felt substrate roll of 450 grams per square meter, and coat the coating emulsion 3 on the dusty surface of the filtrate substrate 1 by a scraper 52 under th...

Embodiment 3

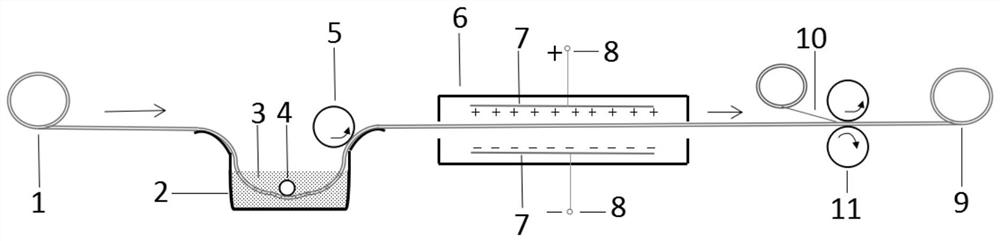

[0085] Example 3 Aramid fiber and glass fiber composite needle felt filter material

[0086] The specific manufacturing method of aramid fiber and glass fiber composite needle felt filter material can be manufactured by impregnation:

[0087] Take the styrene-acrylic emulsion with a solid content of 45%, add water to it for dilution, and make the solid content 25%. Add titanium germanate piezoelectric material powder with a mass fraction of 15% and a median diameter of 10 μm, and BaTiO with a mass fraction of 10% and a median diameter of 20 μm 3 Powder, stir evenly, pour into the tank container.

[0088] Take 500 grams per square meter of aramid fiber and glass fiber surface layer, needle felt substrate roll of aramid fiber base cloth, impregnate the emulsion through the submerged type, and squeeze it through the squeeze roller to make the emulsion enter the inside of the filter material, and Squeeze off some of the excess lotion as well.

[0089] Send it into a gallery-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com