Preparation method and application of Fe/C composite carrier nitrogen and phosphorus removal material based on limonite

A composite carrier, denitrification and phosphorus removal technology, applied in chemical instruments and methods, alkali metal compounds, water/sewage treatment, etc., can solve problems such as high price and limited adsorption capacity, achieve high porosity, reduce preparation cost, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

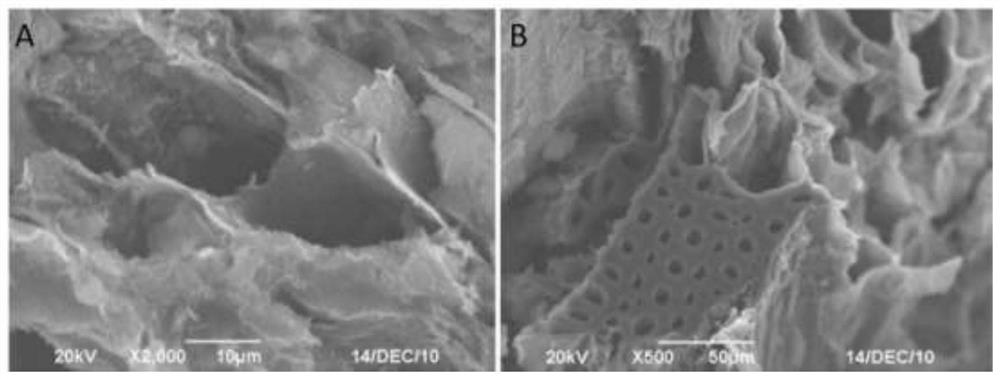

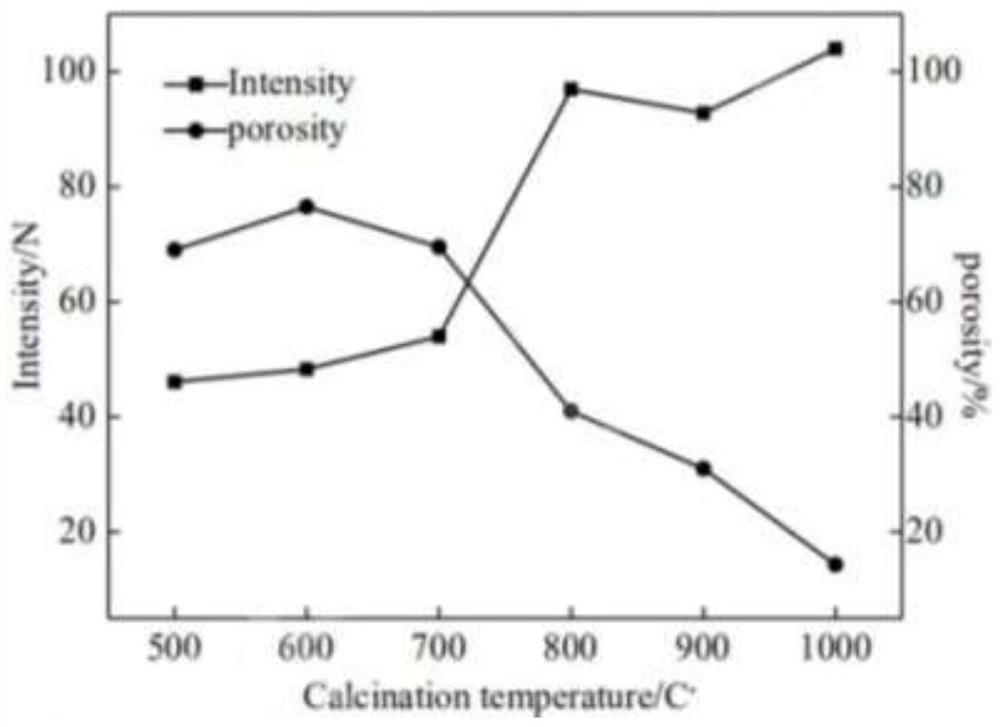

[0017] Example 1: Limonite, straw and attapulgite clay were crushed and sieved to obtain powder with an aperture of 0.1-2mm, and the limonite powder, straw powder and attapulgite clay powder were mixed in a mass ratio of 2:2 : 1 mixed to get the mixture powder, add water to adjust the water content to 12%, put it in the ball forming plate, rotate at a speed of 400r / min for 2.5 hours to get the wet mixture granules, dry at 105°C for 5 hours to get the dry mixture granules, put them in a high temperature tube In a type furnace, calcined at 700°C for 20 hours under a nitrogen atmosphere to obtain a limonite-based Fe / C composite carrier denitrification and phosphorus removal material 1, such as figure 1 As shown, the material prepared by the present invention has a porous structure with a large pore size, such as figure 2 As shown, the porosity can be as high as 64%, and the grain strength can reach 58N,.

Embodiment 2

[0018] Example 2: Limonite, straw and attapulgite clay were crushed and sieved to obtain powder with an aperture of 0.1-2mm, and the limonite powder, straw powder and attapulgite clay powder were mixed in a mass ratio of 1:1 : 0.5 mixed to get the mixture powder, add water to adjust the water content to 12%, place it in a ball forming plate, rotate at a speed of 500r / min for 2.5 hours to obtain wet mixture particles, dry at 105°C for 5 hours to obtain dry mixture particles, place in a high temperature tube In a type furnace, calcined at 800°C for 20 hours under a nitrogen atmosphere to obtain a limonite-based Fe / C composite carrier denitrification and phosphorus removal material 2, such as figure 2 As shown, the porosity of the material prepared by the present invention can reach 40%, and the particle strength can reach 90N.

Embodiment 3

[0019] Example 3: Limonite, straw and attapulgite clay were crushed and sieved to obtain powder with an aperture of 0.1-2 mm, and the limonite powder, straw powder and attapulgite clay powder were mixed in a mass ratio of 1.5:1 : 0.5 mixed to get the mixture powder, add water to adjust the water content to 12%, put it in the ball forming plate, rotate at a speed of 450r / min for 2.5 hours to get the wet mixture granules, dry at 105°C for 5 hours to get the dry mixture granules, put them in a high temperature tube In a type furnace, calcined at 600°C for 20 hours under a nitrogen atmosphere to obtain a limonite-based Fe / C composite carrier denitrification and phosphorus removal material 3, such as figure 2 As shown, the material prepared by the present invention has a high porosity up to 78%, and a grain strength up to 54N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com