Method for recovering low-grade copper-sulfur ore containing secondary copper

A recovery method and low-grade technology, which can be used in chemical instruments and methods, wet separation, solid separation, etc., and can solve problems such as consumption of mineral processing agents and equipment corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

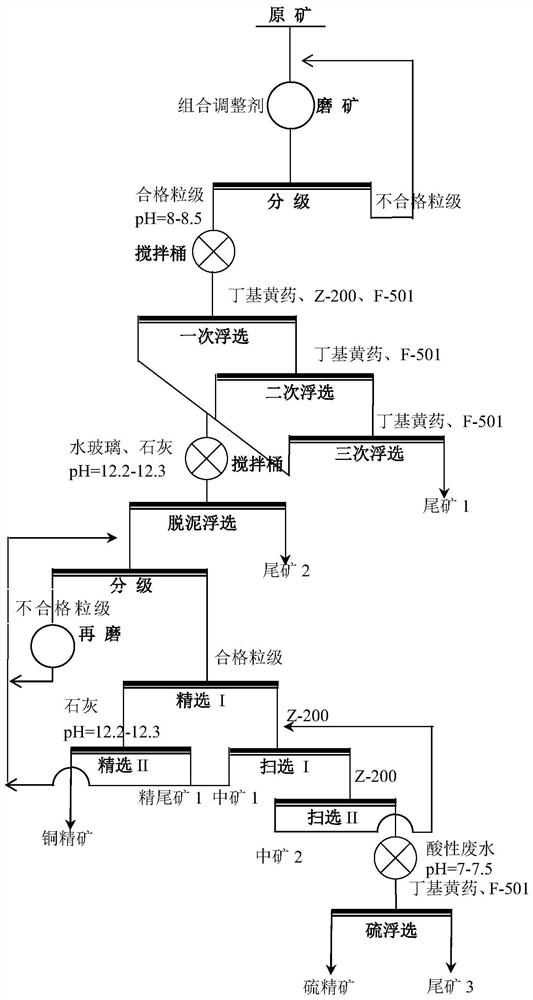

Method used

Image

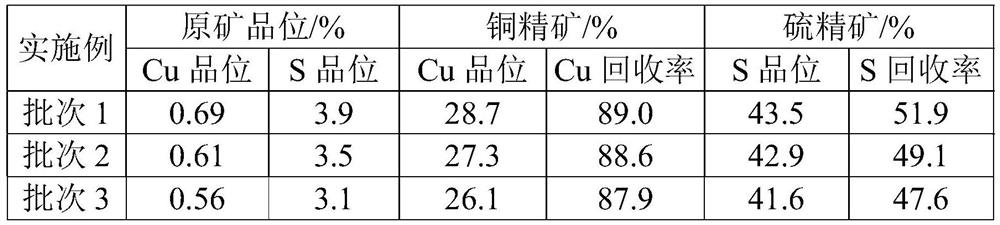

Examples

Embodiment 1

[0031] The copper-sulfur ore mined in an open-pit mine, the main property of the ore in the surface layer is mainly kaolin, and the secondary copper sulfide content is as high as 41.29%. The secondary copper sulfide is in the process of crushing and grinding. Easy to oxidize and produce a large amount of copper ions. Copper ions not only consume chemicals, but also activate pyrite, which increases the difficulty of copper-sulfur separation and affects the separation effect of copper-sulfur. The free copper oxide content is up to 22.13%, which affects the improvement of copper recovery rate. .

[0032] The composition analysis of a certain batch of minerals in the raw ore of the open-pit mine is shown in Table 1.

[0033] Table 1 Analysis results of raw ore copper

[0034] farewell native copper sulfide secondary copper sulfide free copper oxide bound copper oxide Cu grade Copper content / % 0.229 0.252 0.083 0.046 0.61 Occupancy / % 37.58 41.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com