Low-temperature catalytic denitrification method for aluminum ash final ash

A technology of low-temperature catalysis and aluminum ash, which is applied in chemical instruments and methods, aluminum compounds, alkali metal aluminate/aluminum oxide/aluminum hydroxide preparation, etc. It can solve the problems of high temperature, reduce energy consumption, avoid threats, Effect of Improving AlN Conversion Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

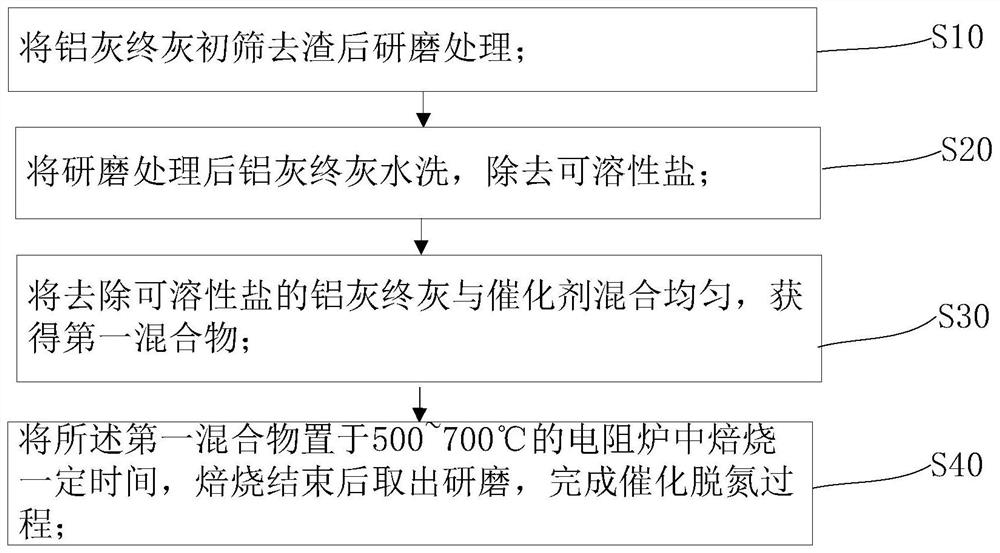

[0029] S10 pretreatment, the final ash of aluminum ash is first sieved to remove slag, then ground and passed through a 150-mesh sieve.

[0030] S20 Wash the final ash of aluminum ash after grinding to remove soluble salt.

[0031] S30 Mix sodium fluoride, potassium hydroxide, sodium metaaluminate, and sodium carbonate in proportion to obtain a catalyst, mix the catalyst with aluminum ash final ash ball mill for removing soluble salts, and place them in a crucible to obtain a first mixture, Wherein the catalyst is 10% of the dry weight of the aluminum ash.

[0032] S40 Place the crucible containing the first mixture in a resistance furnace at 500° C. for 5 hours, and after the calcination, take it out and grind it to complete the catalytic denitrification process. The nitrogen content of the aluminum ash slag after denitrification treatment is tested to be less than or equal to 1%.

Embodiment 2

[0034] S10 pretreatment, the aluminum ash final ash is first screened to remove slag, then ground and passed through a 120-mesh sieve. S20 Wash the final aluminum ash after grinding to remove soluble salt

[0035] S30 Mix cryolite, sodium peroxide, sodium hydroxide, and sodium carbonate in proportion to obtain a catalyst, mix the catalyst with aluminum ash final ash ball mill for removing soluble salts, and place them in a crucible to obtain a first mixture, wherein The catalyst is 40% of the dry weight of the aluminum ash.

[0036] S40 Place the crucible containing the first mixture in a resistance furnace at 600° C. for 4 hours and roast it. After the roasting, take it out and grind it to complete the catalytic denitrification process. The nitrogen content of the aluminum ash slag after denitrification treatment is tested to be less than or equal to 1%.

Embodiment 3

[0038] S10 pretreatment, the final ash of aluminum ash is first sieved to remove slag, then ground and passed through a 150-mesh sieve.

[0039] S20 Wash the final ash of aluminum ash after grinding to remove soluble salt.

[0040] S30 Mix sodium fluoride, sodium peroxide, potassium hydroxide, and sodium carbonate in proportion to obtain a catalyst, mix the catalyst with aluminum ash final ash ball mill for removing soluble salts, and place them in a crucible to obtain a first mixture, wherein The catalyst is 50% of the dry weight of the aluminum ash.

[0041] S40 Place the crucible containing the first mixture in a resistance furnace at 700° C. for 2 h, take it out and grind it after the calcination, and complete the catalytic denitrification process. The nitrogen content of the aluminum ash slag after denitrification treatment is tested to be less than or equal to 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com