Magnesium oxychloride cement and preparation method thereof

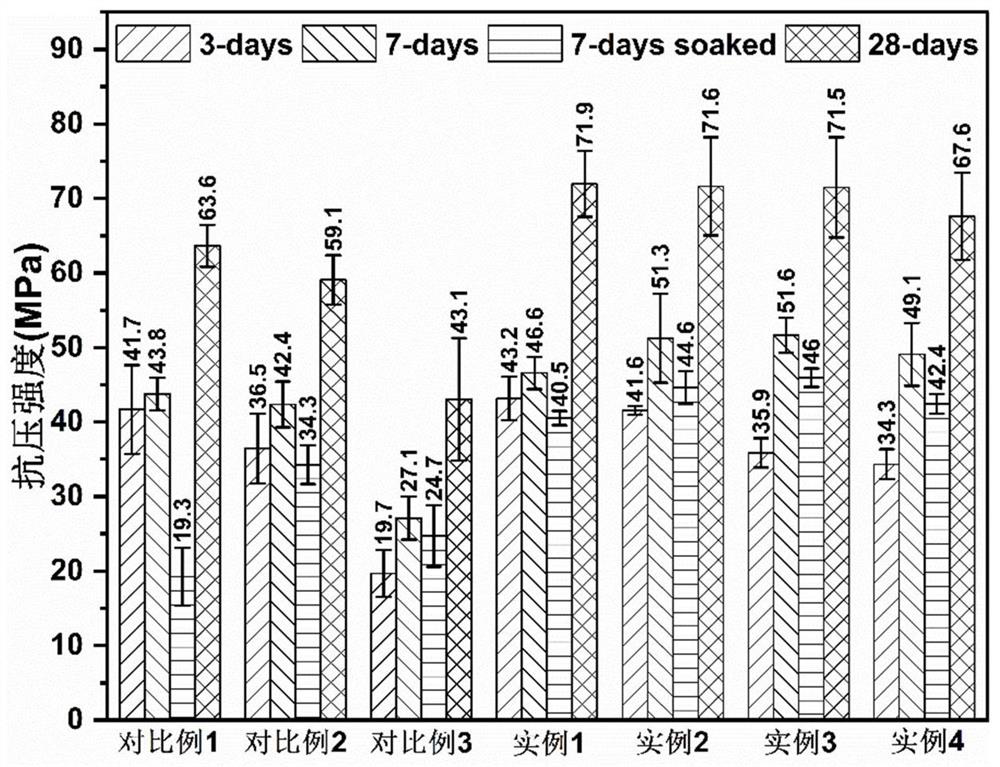

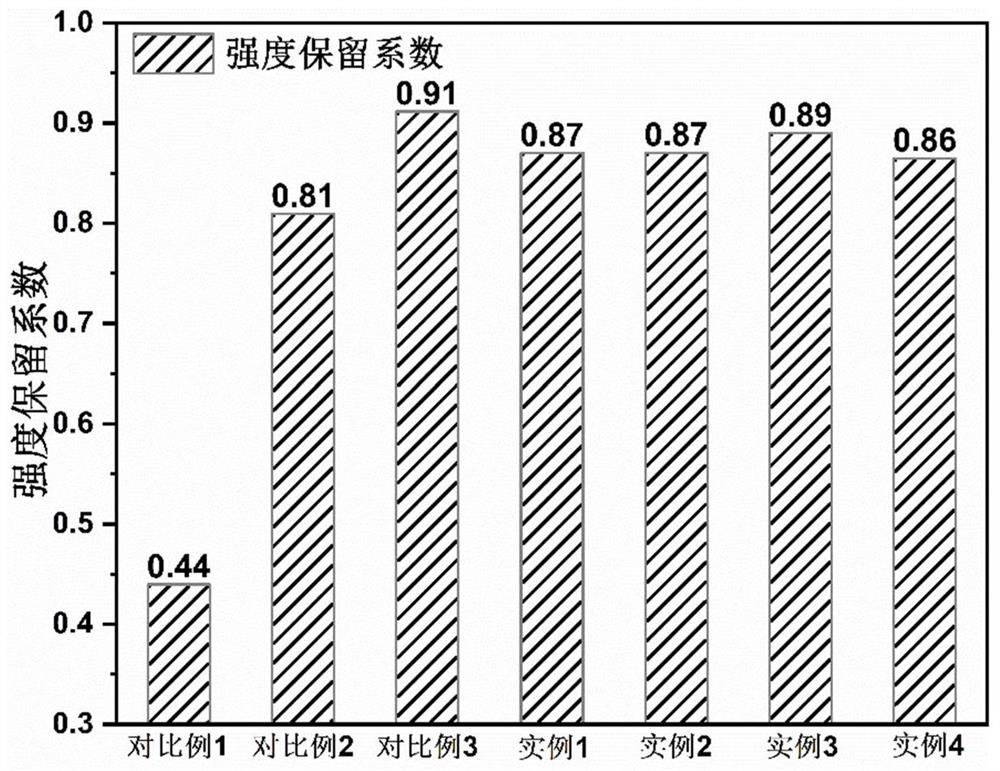

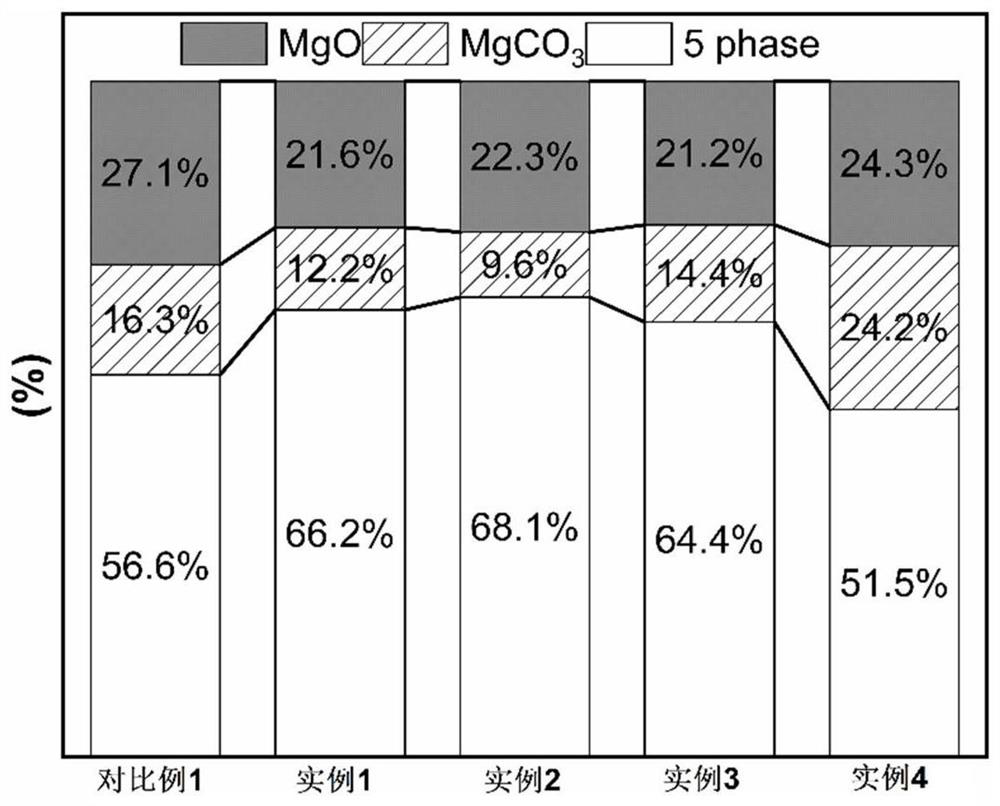

A technology of magnesium oxychloride cement and light-burned magnesia, which is applied in the direction of manufacturing tools and ceramic molding machines, can solve the problems of mechanical property damage, achieve the effects of reducing crack formation, excellent water resistance and strength, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Dissolving 0.63 parts by mass of phytic acid in 126 parts by mass of water, and stirring evenly at 25±2°C to form an aqueous solution of phytic acid;

[0036] (2) 205 parts by mass of magnesium chloride hexahydrate are added to the phytic acid aqueous solution prepared in (1), and stirred evenly;

[0037] (3) 315 parts by mass of lightly burned heavy magnesium oxide are then added to the mixed solution obtained in step (2), and stirred for 5 minutes to form a uniform cement slurry;

[0038] (4) pour into the mold and vibrate, and release the mold after curing for 24 hours under the condition of 25±2°C;

[0039] (5) Curing at 25±2°C for 28 days after demoulding to obtain organic-inorganic hybrid modified high-performance magnesium oxychloride cement.

Embodiment 2

[0041] (1) Dissolving 1.26 parts by mass of phytic acid in 126 parts by mass of water, and stirring evenly at 25±2°C to form an aqueous solution of phytic acid;

[0042] (2) 205 parts by mass of magnesium chloride hexahydrate are added to the phytic acid aqueous solution prepared in (1), and stirred evenly;

[0043] (3) 315 parts by mass of lightly burned heavy magnesium oxide are then added to the mixed solution obtained in step (2), and stirred for 5 minutes to form a uniform cement slurry;

[0044] (4) pour into the mold and vibrate, and release the mold after curing for 24 hours under the condition of 25±2°C;

[0045] (5) Curing at 25±2°C for 28 days after demoulding to obtain organic-inorganic hybrid modified high-performance magnesium oxychloride cement.

Embodiment 3

[0047] (1) Dissolving 1.9 parts by mass of phytic acid in 126 parts by mass of water, stirring evenly at room temperature to form an aqueous solution of phytic acid;

[0048] (2) 205 parts by mass of magnesium chloride hexahydrate are added to the phytic acid aqueous solution prepared in (1), and stirred evenly;

[0049] (3) 315 parts by mass of lightly burned heavy magnesium oxide are then added to the mixed solution obtained in step (2), and stirred for 5 minutes to form a uniform cement slurry;

[0050] (4) pour into the mold and vibrate, and release the mold after curing for 24 hours under the condition of 25±2°C;

[0051] (5) Curing at 25±2°C for 28 days after demoulding to obtain organic-inorganic hybrid modified high-performance magnesium oxychloride cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com