Preparation method of 2-methyltetrahydrofuran-3-thiol

A technology of methyltetrahydrofuran and mercaptan, applied in the direction of organic chemistry and the like, can solve the problems of high cost of treatment of three wastes, difficult rectification impurities in products, many unqualified products, etc., and achieves the effects of high product quality, easy purification, and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

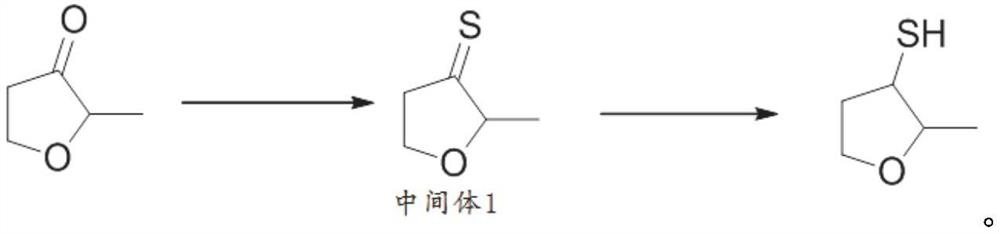

[0026] The synthesis process of the preparation method provided by the invention only needs two steps, the operation is simple, the three wastes are less, and the yield is high.

[0027] The solvent for preparing intermediate 1 from bread ketone through vulcanization reaction can be tetrahydrofuran, dichloromethane, acetonitrile, toluene, etc. However, in the process of vulcanizing bread ketone with a vulcanizing agent, the viscosity of the solution will increase, and even the phenomenon that the material becomes spherical , thereby affecting the complexity of the purification process and at the same time affecting the product yield. In some examples of this embodiment, the solvent for preparing intermediate 1 from bread ketone is acetonitrile. It is found through experiments that when acetonitrile is used as the solvent, the purification process is simple and the product yield is further improved.

[0028] In some examples of this embodiment, the vulcanizing agent is P 2 S ...

Embodiment 1

[0040] In a 1L clean four-necked bottle equipped with stirring and a thermometer, add 200g (2mol) of bread ketone as the raw material, add 600g of tetrahydrofuran, start stirring, heat the oil bath slowly to 50°C, and add P 2 S 5 310g (0.7eq) was controlled at 55°C, added and kept warm at 50°C for 5 hours. The solid was in a dispersed state at the beginning, and then gradually became sticky, adhered to the wall and agglomerated. The reaction was monitored by TLC. The developer was (ethyl acetate: petroleum ether = 1 : 5) After the reaction is finished, lower the temperature to 10° C., add dropwise saturated aqueous sodium carbonate solution to adjust the pH to 7, continue to stir for 10 minutes, remove the solid by suction filtration, add 100 g of water to the filtrate, and extract and stand for layering with dichloromethane 150*3. Combined organic phases were precipitated to obtain intermediate 1 crude product 170g, GC content 90%, yield 70% MS (ES + ): M / Z=116 (M + ).

...

Embodiment 2

[0043]In a 1L clean four-necked bottle equipped with stirring and a thermometer, add 200g (2mol) of the raw material bread ketone, add 600g of dichloromethane, start stirring, heat the oil bath slowly to 40°C, and add P 2 S 5 310g (0.7eq) was controlled at 45°C, added and kept warm at 50°C for 5 hours. The solid was in a dispersed state at the beginning, and then gradually became sticky, adhered to the wall and agglomerated. The reaction was monitored by TLC. The developer was (ethyl acetate: petroleum ether = 1 : 5) After the reaction is finished, lower the temperature to 10° C., add dropwise saturated aqueous sodium carbonate solution to adjust the pH to 7, continue to stir for 10 minutes, remove the solid by suction filtration, add 100 g of water to the filtrate, and extract and stand for layering with dichloromethane 150*3. Combine the organic phases and remove the solvent to obtain 200g of intermediate 1 crude product, GC content 90%, yield 85% MS (ES + ): M / Z=116 (M +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com