Amino-silicone oil modified waterborne polyurethane and preparation method thereof

A water-based polyurethane, amino silicone oil technology, applied in the direction of repelling fibers to liquids, textiles and papermaking, fiber processing, etc., can solve the problems of limited cross-linking density, poor water resistance, solvent resistance, and the influence of the service life of fabrics, etc. Achieve the effect of low surface tension, great application value and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

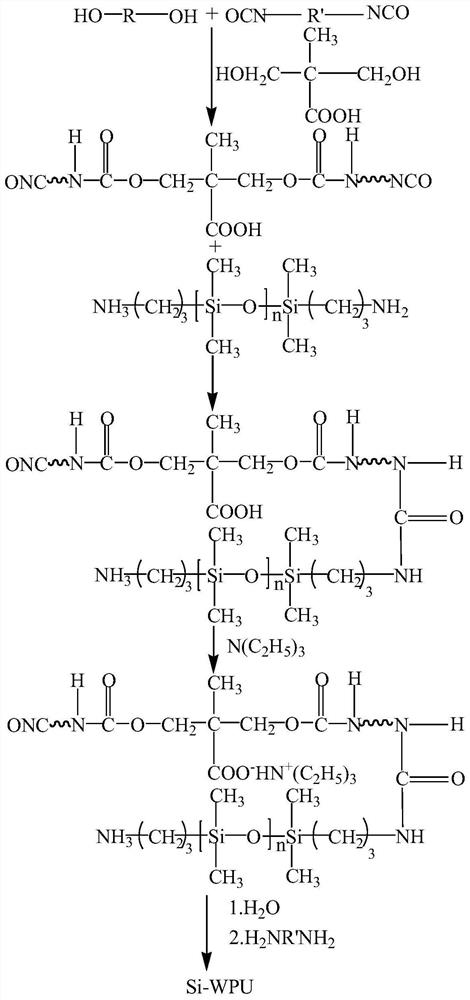

[0044] A kind of preparation method of amino silicone oil modified water-based polyurethane, its chemical reaction process, such as figure 1 shown, including the following steps:

[0045] (1) 12.5g PCL-1000 or PPG-1000, 4.88g HDI or IPDI, 0.02g DBTDL were added to a three-necked flask and mixed, and the reaction was carried out at a low speed at 90°C for 2h to obtain a prepolymer;

[0046] Take the prepolymer to measure the content of -NCO group in the reactant, it should reach the theoretical value;

[0047] (2) Add 0.9g DMPA to the prepared prepolymer, react for 1h, and carry out chain extension; after the chain extension is completed, add 0.6g ASO to carry out graft modification, and continue to react at 90 °C for 2h, chain extension and Silicon is introduced, and the viscosity of the system is adjusted with NMP throughout the process;

[0048] (3) stop heating the mixed solution after chain extension modification, take out and cool down for 30min, then add 0.6g of TEA to...

Embodiment 2

[0053] A preparation method of aminosilicone oil-modified water-based polyurethane, comprising the following steps:

[0054] (1) 13.5g PCL-1000 or PPG-1000, 4.90g HDI or IPDI, 0.02g DBTDL were added to a three-necked flask and mixed, and the prepolymer was prepared by stirring at a low speed for 2 hours at 90°C;

[0055] Take the prepolymer to measure the content of -NCO group in the reactant, it should reach the theoretical value;

[0056] (2) Add 1.0g DMPA to the prepared prepolymer, react for 1h, and carry out chain extension; after the chain extension is completed, add 0.9g ASO to carry out graft modification, and continue the reaction at 90 °C for 2h, chain extension and Silicon is introduced, and the viscosity of the system is adjusted with NMP throughout the process;

[0057] (3) stop heating the mixed solution after chain extension modification, take out and cool down for 30min, and then add 0.7g of TEA to it for 40min to obtain a neutralized salt solution mixed syste...

Embodiment 3

[0062] A preparation method of aminosilicone oil-modified water-based polyurethane, comprising the following steps:

[0063] (2) 14.7g PCL-1000 or PPG-1000, 5.0g HDI or IPDI, 0.04g DBTDL, were added to a three-necked flask and mixed, and the prepolymer was prepared by stirring at a low speed for 2 hours at 90°C;

[0064] Take the prepolymer to measure the content of -NCO group in the reactant, it should reach the theoretical value;

[0065] (2) Add 1.1g DMPA to the prepared prepolymer, react for 1h, and carry out chain extension; after the chain extension is completed, add 1.46g ASO to carry out graft modification, and continue to react at 90°C for 2h to extend chain And introduce silicon element, and adjust the viscosity of the system with NMP in the whole process;

[0066] (3) stop heating the mixed solution after chain extension modification, take out and cool down for 30min, then add 0.8g of TEA to it and react for 40min to obtain a neutralized salt solution mixed system;...

PUM

| Property | Measurement | Unit |

|---|---|---|

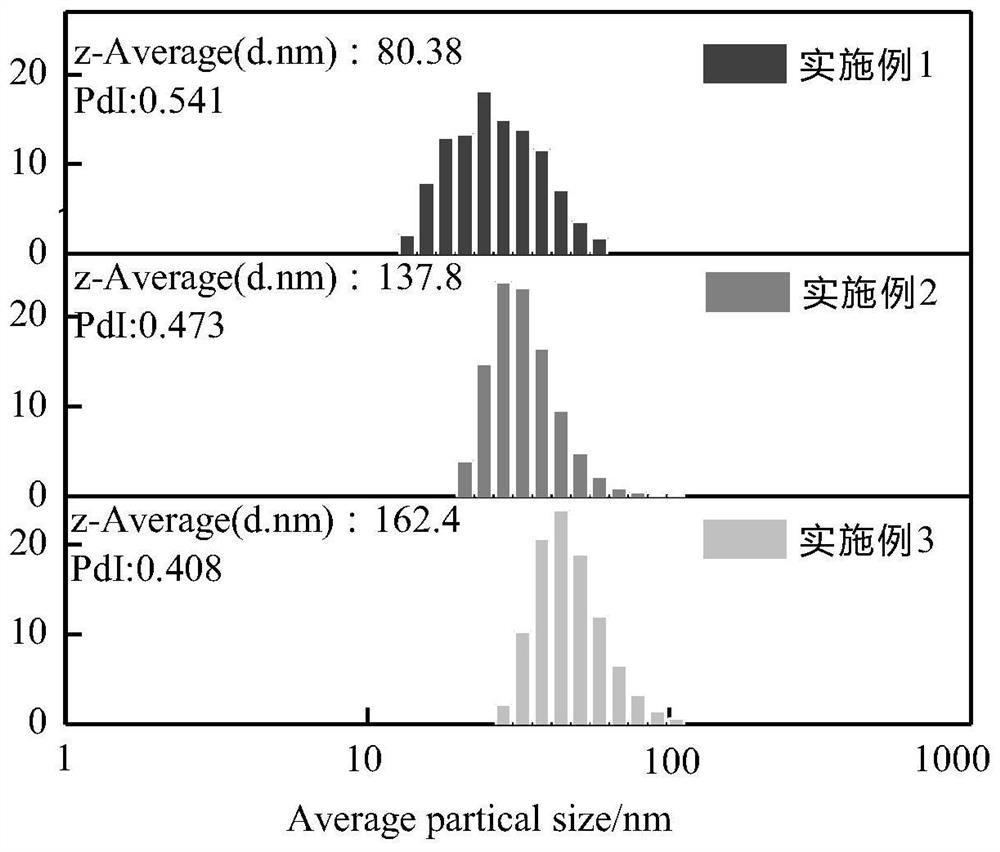

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com