Alkoxy group-containing triphenylamine donor group terpolymer, electric storage device and preparation thereof

A terpolymer and alkoxy technology, applied in electrical components and other directions, can solve the problems of high price, complex production process of multi-level data storage materials, low multi-level storage yield, etc., and achieves high selectivity, high The effect of enhancing the degree of conjugation and hole transport, and increasing the HOMO energy level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0070] The preparation of embodiment 1 terpolymer:

[0071] (1) Preparation of monomer M1 (9,12-dibromo-7H-benzoimidazo(2,1-a)benzo(de)isoquinolin-7-one): in N 2 Under the atmosphere, add 1.8-naphthalene dicarboxylic anhydride and 3,6-dibromo-1,2-phenylenediamine at a molar ratio of 1:1, put 10 mL of glacial acetic acid in a three-necked flask, stir and heat up to the reflux of the solution, and then keep constant temperature React for 6 hours, cool the reaction to room temperature, filter the crude product after precipitation, wash with deionized water until neutral, put the obtained crude product in a vacuum drying oven for drying, and use column chromatography to separate and purify the dried crude product , to obtain monomer M1; the vacuum drying temperature is 80-85°C, the vacuum drying time is 12h, and the vacuum drying pressure is -30--29KPa;

[0072] (2) Preparation of monomer M2 (N,N-bis(4-bromophenyl)-N-(4-methoxy)aniline): 1.70g (13.83mmol) 4-methoxyaniline, 8.08g ...

Embodiment 2 3

[0079] Example 2 Terpolymer is used to prepare electric storage device

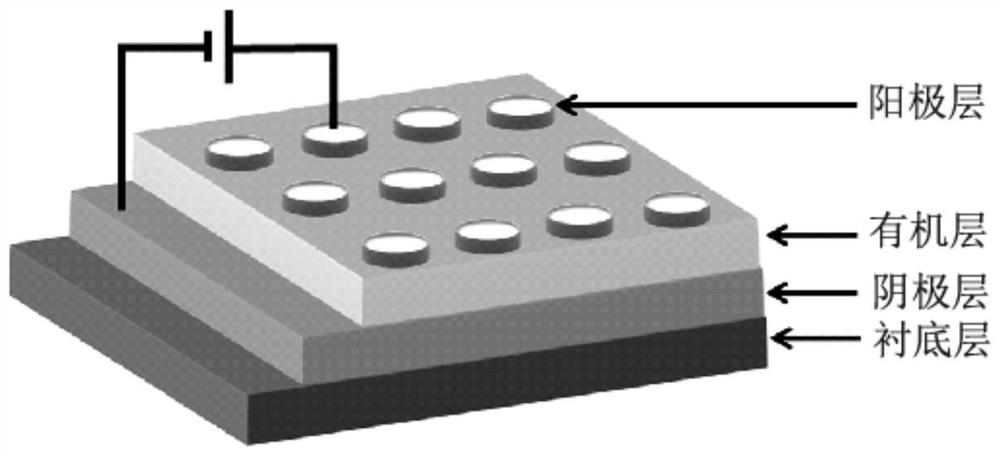

[0080] In the present invention, the terpolymer prepared in Example 1 is used as an organic layer to prepare an electric storage device. The structure diagram of the electric storage device is as follows figure 1 As shown, it includes a substrate layer, a cathode layer, an organic layer and an anode layer, the cathode is disposed on the substrate, the organic layer is disposed on the cathode, and the anode is disposed on the organic layer.

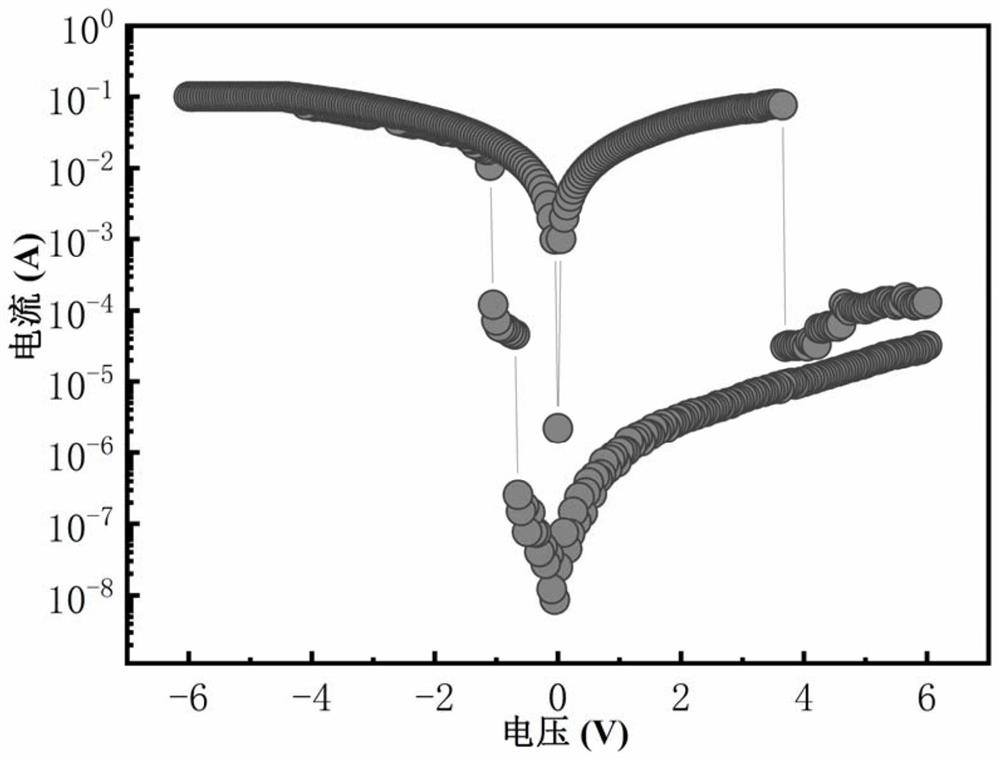

[0081] The organic layer of the present invention is formed from the terpolymer prepared in Example 1, and the terpolymer is used to make storage materials for electric storage devices. In the terpolymer, the electron-rich fluorenyl and triphenylamine groups are excellent electron-donor units, and the introduction of electron-donating groups into the main chain of the polymer can effectively improve the hole transport ability of the polymer, making the copolymerizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com