Polyacetylene amide compound as well as preparation method and application thereof

A polyalkyne amide and compound technology, which is applied in the fields of polymer chemistry and materials science, can solve the problems of difficulty in the preparation of alkynoic acid monomers, limit the preparation and application of polyalkyne amides, etc., and achieves easy availability of catalysts, low cost, and good thermal stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

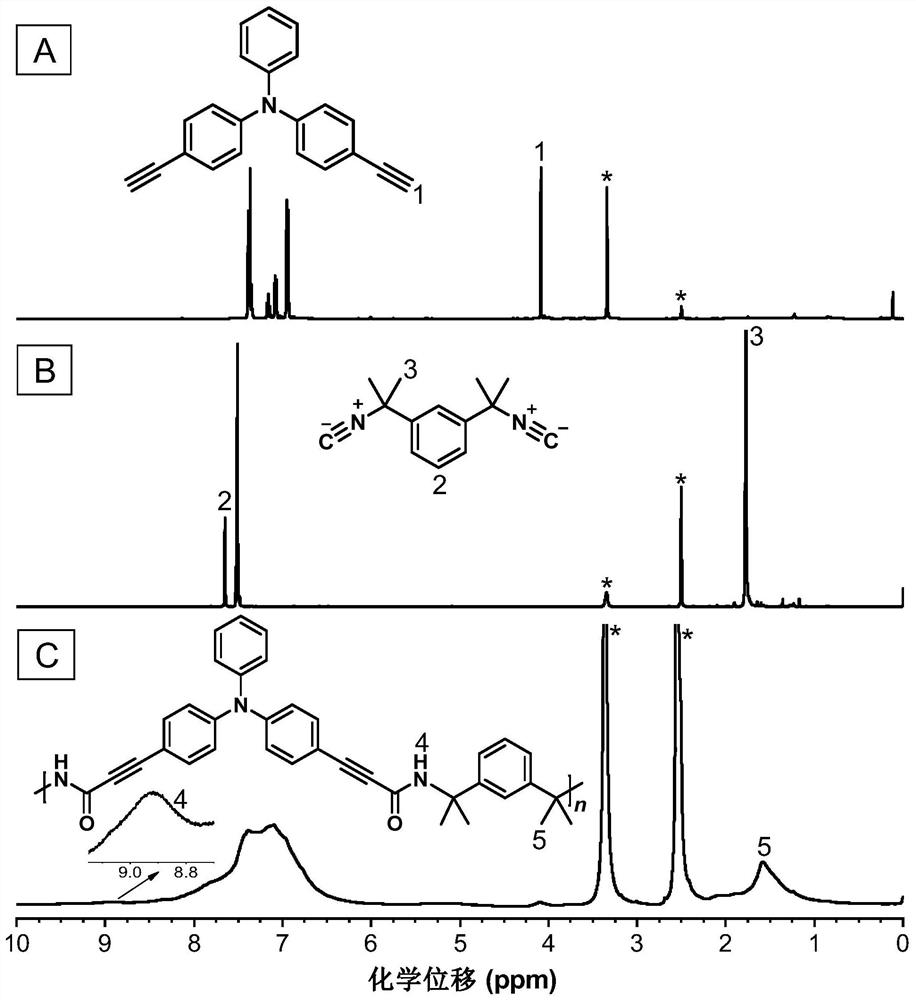

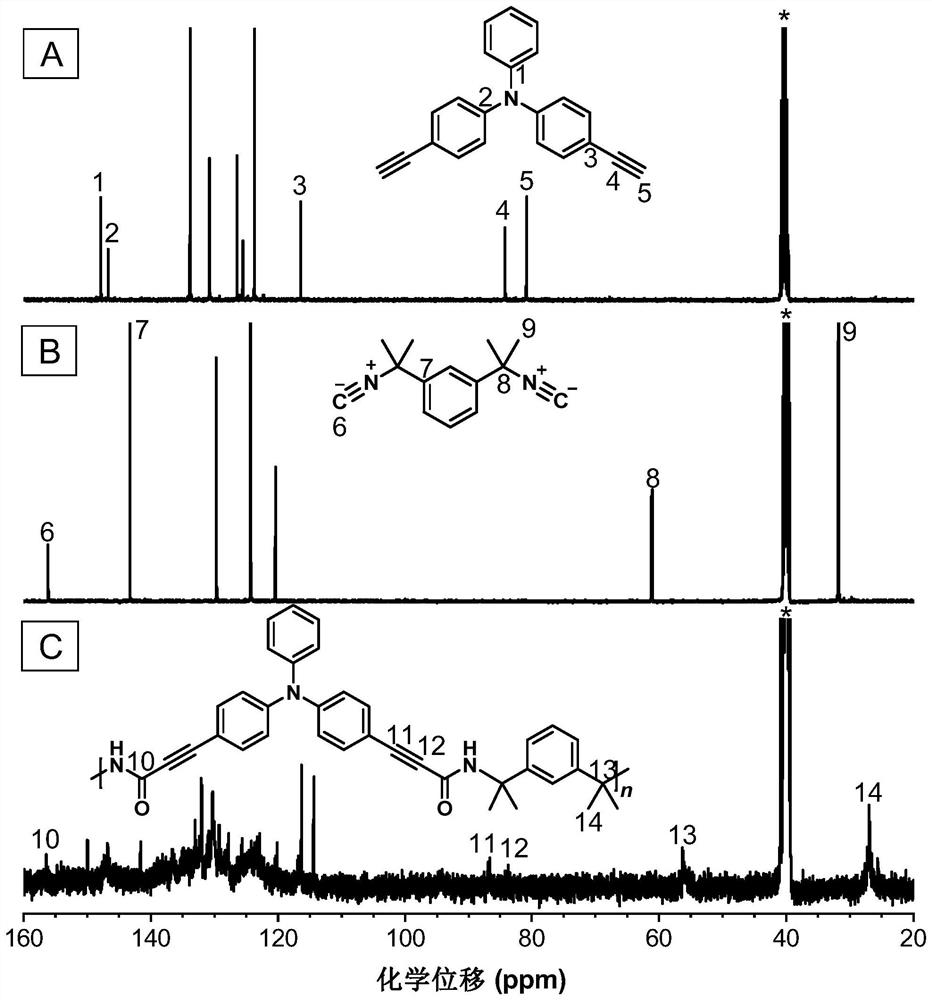

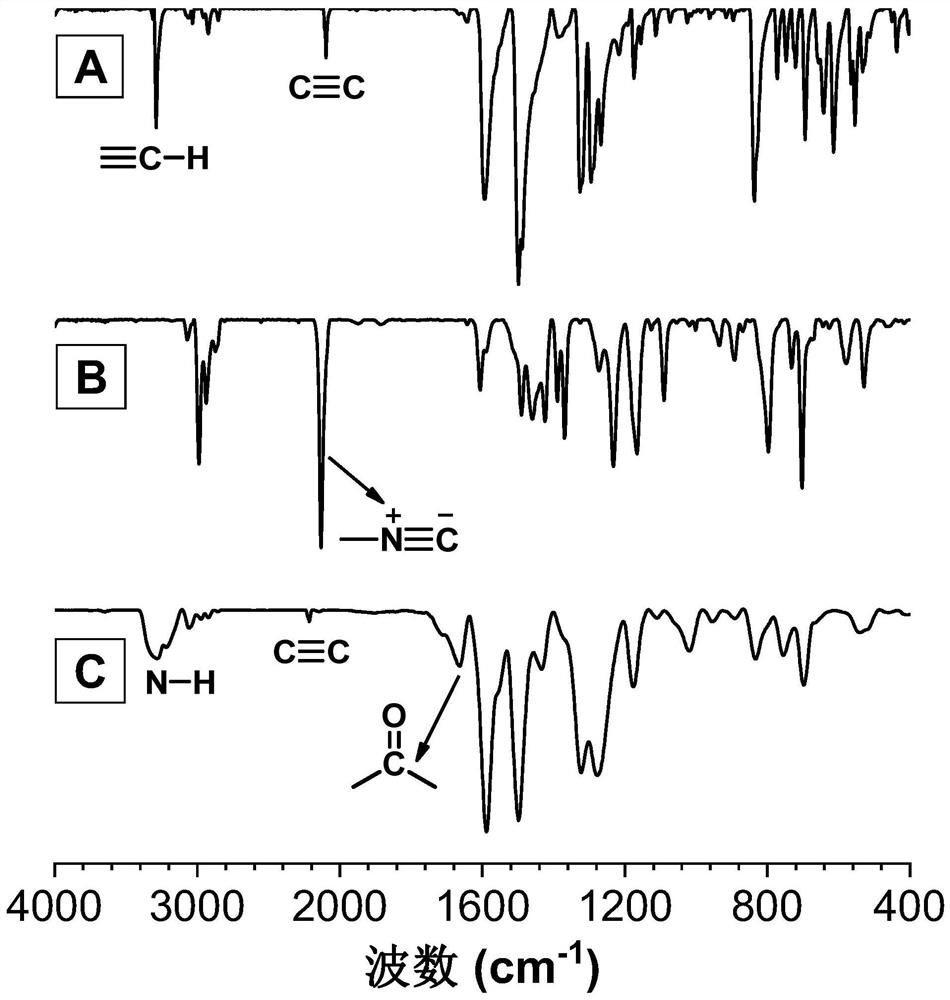

[0048] A polyalkyne amide compound, its structural formula is as shown in P1:

[0049]

[0050] The polyalkyne amide compound is prepared by the polymerization reaction of water, difunctional terminal alkyne monomer and difunctional isonitrile monomer, and the reaction equation is as formula (1):

[0051]

[0052] Among them, the monomer M1 can be synthesized by referring to the preparation method of the literature (ACS Macro Lett., 2019, 8(2): 101-106); the monomer N1 can be synthesized by referring to the literature (Macromolecules, 2021, 54(9): 4112-4119 and J.Am.Chem.Soc., 2018,140(19):6156-6163) synthesis method.

[0053] The preparation steps of described polyalkyne amide compounds are as follows:

[0054]Add anhydrous cobalt bromide (CoBr 2 ) (0.01mmol, 2.2mg), silver nitrate (AgNO 3 ) (0.4mmol, 68mg), bis(2-diphenylphosphophenyl) ether (DPEphos) (0.08mmol, 43.1mg,) and M1 (0.2mmol, 58.6mg), pumped nitrogen three times, under nitrogen atmosphere , injected N1 ...

Embodiment 2

[0057] A kind of polyalkyne amide compound, its structural formula is as shown in P2:

[0058]

[0059] The polyalkyne amide compound is prepared by the polymerization reaction of water, difunctional terminal alkyne monomer and difunctional isonitrile monomer, and the reaction equation is as formula (2):

[0060]

[0061] Wherein, the synthesis method of monomers M1 and N2 is the same as in Example 1.

[0062] The preparation steps of described polyalkyne amide compounds are as follows:

[0063] Add anhydrous CoBr to a 10 mL dry polymerization tube equipped with a magnetic stir bar 2 (0.02mmol, 4.4mg), AgNO 3 (0.4mmol, 68mg), DPEphos (0.08mmol, 43.1mg), M1 (0.2mmol, 58.6mg) and N2 (0.2mmol, 32.8mg), pump nitrogen three times, under nitrogen atmosphere, inject 0.33mL DCE , and finally water (1.4 mmol, 25 μL) was injected, and the reaction system was reacted at 40° C. for 8 hours. After the reaction, cool to room temperature, add 3.5mL DCE, stir and dilute. Then the o...

Embodiment 3

[0066] A kind of polyalkyne amide compound, its structural formula is as shown in P3:

[0067]

[0068] The polyalkyne amide compound is prepared by the polymerization reaction of water, difunctional group terminal alkyne monomer and bifunctional isonitrile monomer, and the reaction equation is as formula (3):

[0069]

[0070] Wherein, the synthesis method of monomers M1 and N3 is the same as in Example 1.

[0071] The preparation steps of described polyalkyne amide compounds are as follows:

[0072] Add anhydrous CoBr to a 10 mL dry polymerization tube equipped with a magnetic stir bar 2 (0.03mmol, 6.6mg), AgNO 3 (0.4mmol, 68mg), DPEphos (0.08mmol, 43.1mg), M1 (0.2mmol, 58.6mg) and N3 (0.2mmol, 46.0mg), pump nitrogen three times, under nitrogen atmosphere, inject 0.25mL DCE and 0.25 mL DMAc, and finally injected water (2.6 mmol, 47 μL), and the reaction system was reacted at 80° C. for 4 hours. After the reaction, cool to room temperature, add 3.5mL of DCE, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com