Antibacterial easily-degradable plastic bottle cap and preparation method thereof

A technology of easily degradable plastics and bottle caps, applied in the field of antibacterial and easily degradable plastic bottle caps and their preparation, can solve problems such as difficulty in recycling plastic bottle caps, food and drug pollution, separation of plastic bottle caps, etc., and achieve good environmental benefits , The effect of less environmental pollution, improved fluidity and friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

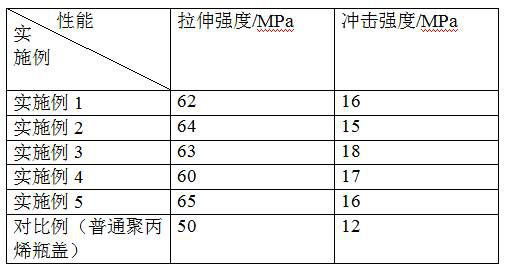

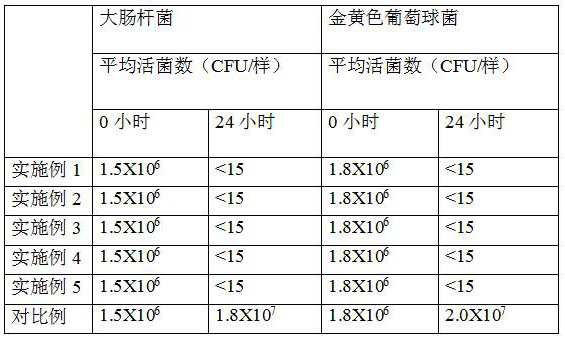

Examples

Embodiment 1

[0040] Sl, first weighed 3 g silyl quaternary ammonium salt, and then sprayed through the atomizer into 1000 ml three-neck flask with a propeller stirrer with nitrogen in advance with 10 gram of the porous titania in the three-necked flask, starting stirring propeller, sufficiently stirred after a uniform, 10 g of citric acid, mix well;

[0041] S2, stand for 1 hour, filtered off with suction, and dried in vacuo to give after trituration organosilicon quaternary ammonium antibacterial agent powder;

[0042] S3, the polylactic acid 50 g, 10 g of polypropylene, 5 grams of silicon ester, 1 g phthalate, hydroquinone twelve (beta] a-hydroxyethyl) ether, 6 g melted and uniformly mixed, and then the silicone organic antibacterial powder is added; after uniformly mixed, at 170 ℃ ~ 230 ℃ by compression molding injection molding machine, to prepare readily degradable antibacterial plastic bottle caps.

Embodiment 2

[0044] Sl, first weighed 8 g of silicon quaternary ammonium salt, and then sprayed onto 1000 ml three-neck flask with a propeller stirrer with nitrogen protected by a nebulizer, previously added 15 g of titanium dioxide in the porous three-necked flask, starting stirring propeller, sufficiently stirred uniformly, adding 15 grams of citric acid, mix well;

[0045] S2, standing for 2 hours, filtered off with suction, and dried in vacuo to give after trituration organosilicon quaternary ammonium antibacterial agent powder;

[0046] S3, the 70 g of polylactic acid, polypropylene, 20 grams, 10 grams oleic acid amide, a plasticizer, 3 g, 10 g chain extender melted and uniformly mixed, and then the organic antibacterial silicone powder is added; mixing the homogeneous after compression molding by an injection molding machine at 170 ℃ ~ 230 ℃ was prepared readily degradable antibacterial plastic bottle caps.

Embodiment 3

[0048] Sl, first weighed 4 g silicon quaternary ammonium salt, and then sprayed onto 1000 ml three-neck flask with a propeller stirrer with nitrogen protected by a nebulizer, previously added 12 g of titanium dioxide in the porous three-necked flask, starting stirring propeller, sufficiently stirred after a uniform, 11 g of citric acid was added, uniformly mixed;

[0049] S2, stand for 1 hour, filtered off with suction, and dried in vacuo to give after trituration organosilicon quaternary ammonium antibacterial agent powder;

[0050] S3, the 55 parts of a polylactic acid, 13 g of polypropylene, organosilanes 6 grams, 2 grams plasticizers, chain extender 7 g mixed uniformly melted, and then the organic antibacterial silicone powder is added; after uniformly mixed by , at 170 ℃ ~ 230 ℃ by compression molding injection molding machine, to prepare readily degradable antibacterial plastic bottle caps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com