Yeast with high yield of isoamyl acetate and its application

A technology of isoamyl acetate and yeast, applied in the field of development of non-Saccharomyces cerevisiae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

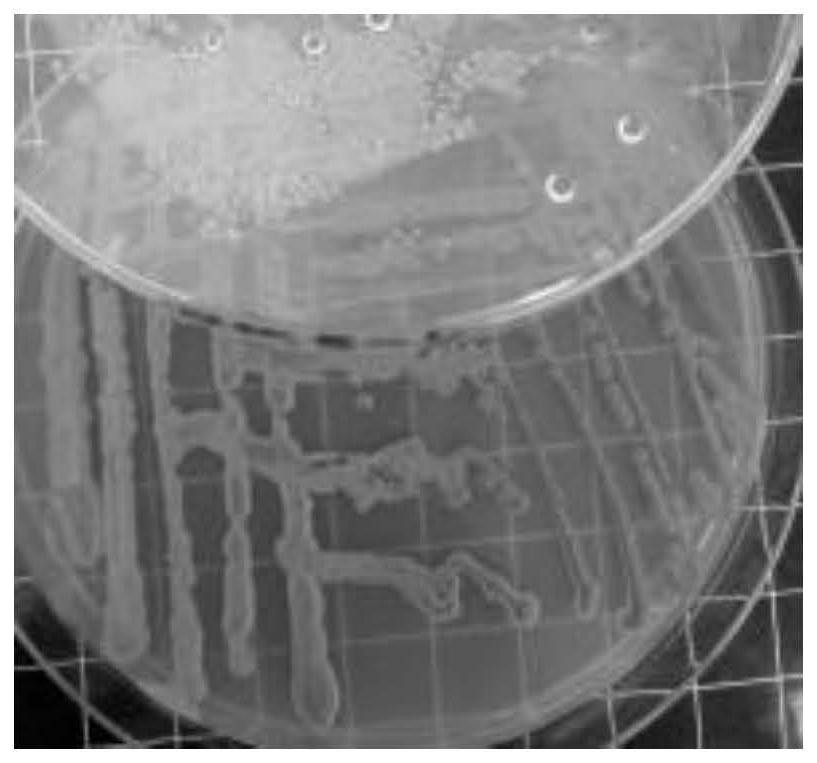

[0034] Example 1 Isolation and identification of high isoamyl acetate-producing yeast strains

[0035] Separation: The sampling cellar is the cellar that has been continuously fermented for more than 5 years in the production workshop of Yibin Wuliangye Co., Ltd. Sampling was taken at 12 days of fermentation, and a special sampler (hollow double-layer stainless steel sleeve) was inserted into the cellar, and the grains from 5 sampling points between 0.5m-1.5m from the surface of the cellar, the center and the surrounding area were taken, and put into In a sterile sampling bag, the ice box was transported back to the laboratory, and the yeast strains were isolated according to the following method within 1 hour after sampling: Dilute the fermented grain sample with sterile water 1000, 10000, and 100000 times respectively, and spread it on the xylose instead Glucose YPD medium (formulation: 1% yeast extract, 2% peptone, 2% xylose, 2% agar, sterilized at 121° C. for 20 min) with ...

Embodiment 2

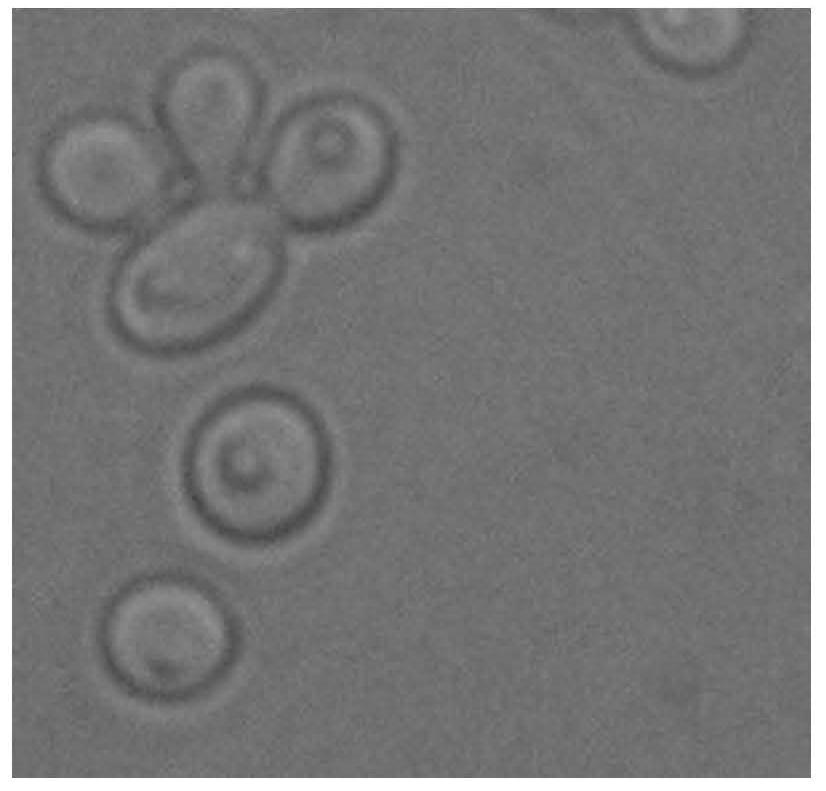

[0037] Embodiment 2 Physiological and biochemical characteristics of solid-state fermentation high-yielding isoamyl acetate yeast of the present invention

[0038] Cultured on L-YPD agar medium at 28°C for 2 days, observed the colonies and cell morphology; Disaccharide, cellobiose, lactose, and melezitose are the only carbon sources in the YNB medium to cultivate yeast, observe its growth, and evaluate its ability to assimilate sugar; inoculate the yeast on the urea medium, and cultivate for 24 hours. The ability of yeast to utilize urea was evaluated according to whether the medium turned red. Inoculate lactic acid YPD medium (pH5.0) with 5mL of bacterial suspension, shake and culture at 100r / min at 20, 24, 28, 32, 36, and 40°C for 36h respectively, test its temperature tolerance, and inoculate with 5mL of bacterial suspension Into lactic acid YPD medium (pH 5.0) with ethanol content of 1, 2, 3, 4, 5, 6, 7, 8% respectively, shake culture at 28°C and 100r / min for 36h, and tes...

Embodiment 3

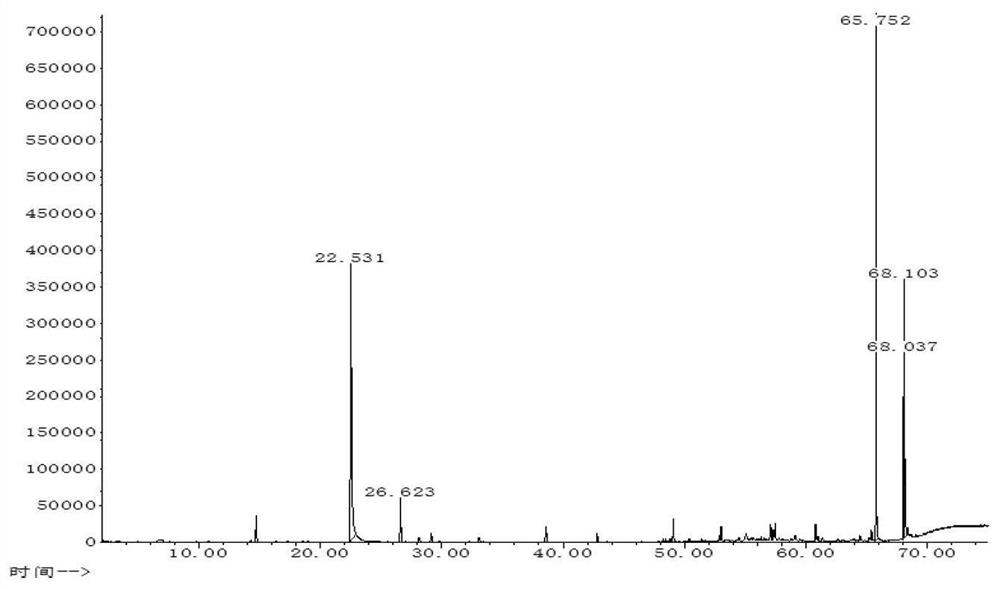

[0041] Example 3 Application of yeast of the present invention in the brewing of Luzhou-flavor liquor

[0042] First, use an inoculation needle to inoculate one loop of yeast strains preserved on the slant into lactic acid YPD liquid medium, culture at 28°C for 1 day, then centrifuge the obtained yeast suspension at 3000rpm for 5min at 25°C, and pour off the supernatant , add sterile water, mix well and centrifuge again under the same conditions, wash the cells, and make a yeast suspension with a concentration of about 0.5OD for future use.

[0043] The yeast was inoculated with 0.1% inoculum into grain grain grains and fermented for 70 days. Compared with the naturally fermented grain grains (control) without yeast inoculation, the main flavor substances produced by the yeast are shown in Table 2. Among them, the content of isoamyl acetate in grain grains increased from 0.007g / kg to 0.341g / kg, the content of β-phenylethanol increased from 0.014g / kg to 0.207g / kg, and the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com