Method for preparing yak skin micromolecular collagen peptide through continuous rotary evaporation desolvation and double enzymolysis

A technology of collagen peptide and double enzymatic hydrolysis, which is applied in the preparation method of peptide, chemical instruments and methods, animal/human protein, etc., can solve the problem that cowhide collagen peptide has not been improved, affects the quality of end products, and the cost of small molecule peptides Advanced problems, to achieve the effect of reducing the burden of filtration, shortening the time of enzymatic hydrolysis, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

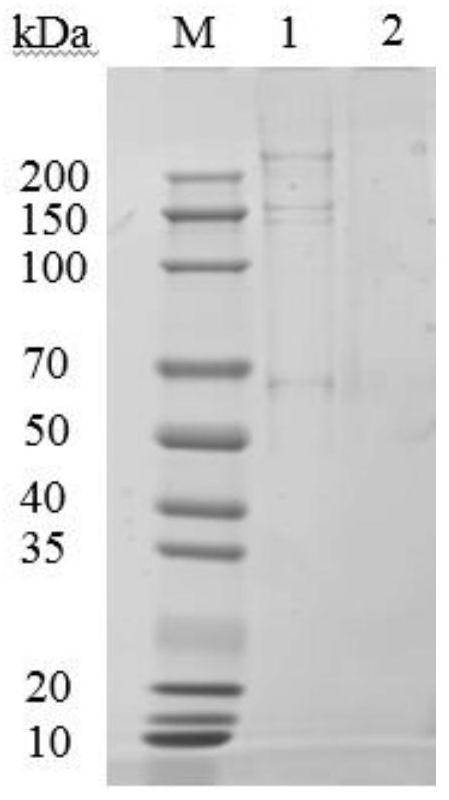

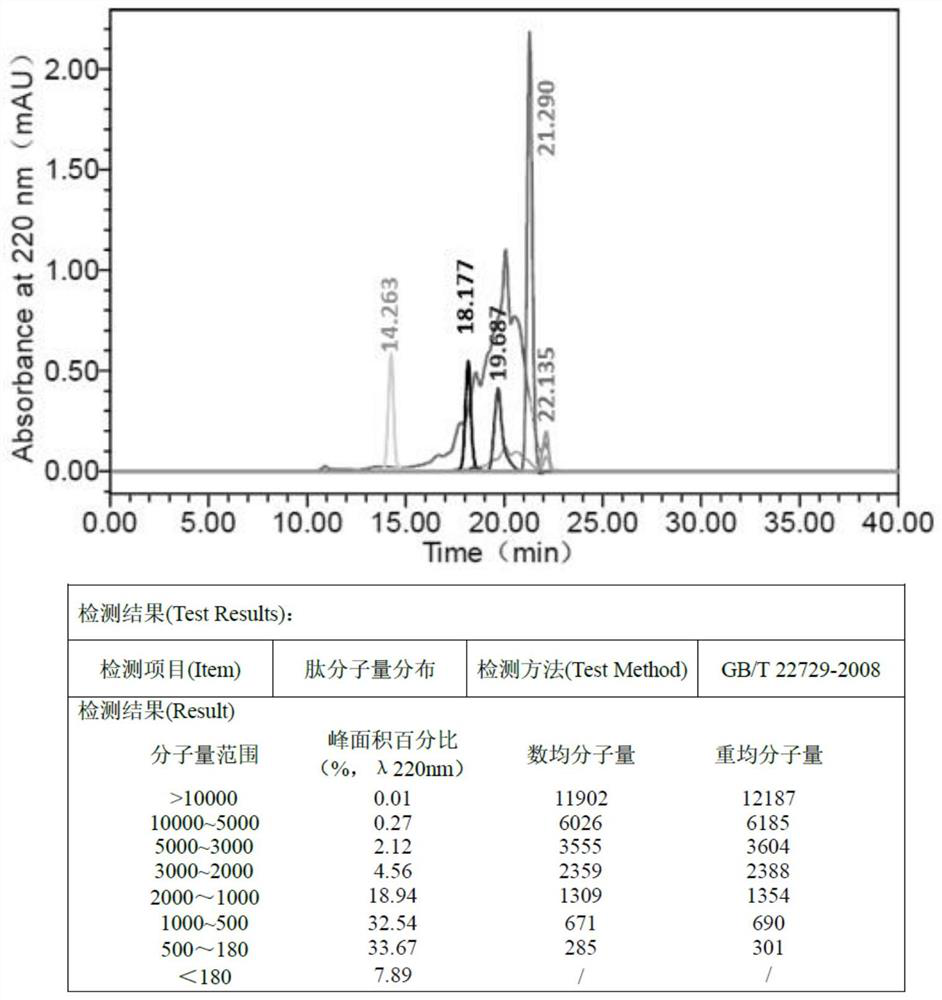

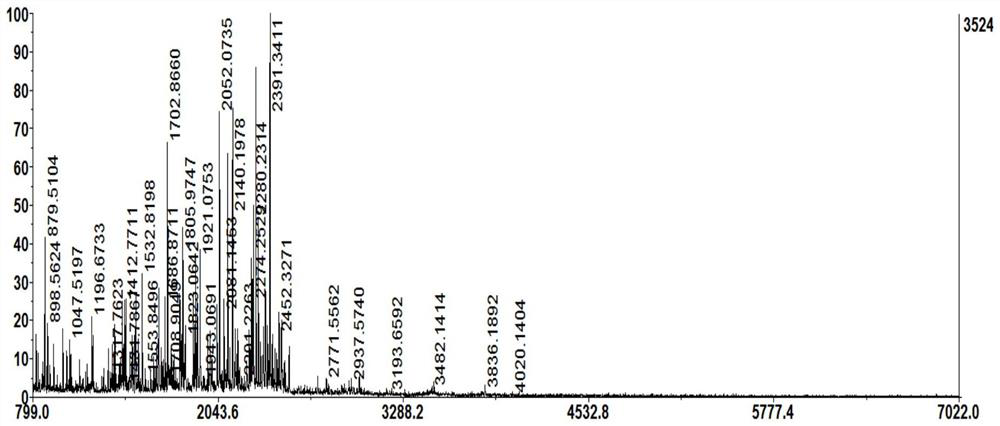

Examples

Embodiment 1

[0032] A method for preparing yak skin small-molecule collagen peptides by continuous rotary evaporation, desolvation, and double enzymatic hydrolysis, which includes (1) pretreatment of yak skin, (2) homogenization, (3) enzymatic hydrolysis, (4) centrifugation, (5) Decolorization, deodorization, desalination, (6) concentrated drying step, the specific steps are as follows:

[0033] (1) Pretreatment: Weigh 50g of fresh yak hide, chop it into 1×1cm blocks after depilation, add soda ash with a mass concentration of 5% to soak for 8 hours at room temperature according to the mass ratio of material to liquid at 1:5kg / kg, After soaking, wash the yak skin with water until it is neutral, then add the yak skin to the salt with a mass concentration of 5% at a mass ratio of 1:5kg / kg, and soak for another 8 hours. After the soaking, wash the yak skin with water Neutral to achieve the purpose of degreasing and removing impurities;

[0034] (2) Homogenization: add 0.05M acetic acid soluti...

Embodiment 2

[0043] A method for preparing yak skin small-molecule collagen peptides by continuous rotary evaporation, desolvation, and double enzymatic hydrolysis, which includes (1) pretreatment of yak skin, (2) homogenization, (3) enzymatic hydrolysis, (4) centrifugation, (5) Decolorization, deodorization, desalination, (6) concentrated drying step, the specific steps are as follows:

[0044] (1) Pretreatment: Weigh 500g of fresh yak hide, chop it into 1×1cm blocks after depilation, add soda ash with a mass concentration of 3% at room temperature for 8 hours at a mass ratio of material to liquid of 1:5kg / kg, After soaking, wash the yak skin with water to neutrality, then add the yak skin to the mass concentration of 3% salt at a mass ratio of 1:5kg / kg, and soak for 8 hours again. After soaking, wash the yak skin with water Neutral to achieve the purpose of degreasing and removing impurities;

[0045] (2) Homogenization: add 0.05M acetic acid solution into 0.05M acetic acid solution wit...

Embodiment 3

[0054] A method for preparing yak skin small-molecule collagen peptides by continuous rotary evaporation, desolvation, and double enzymatic hydrolysis, which includes (1) pretreatment of yak skin, (2) homogenization, (3) enzymatic hydrolysis, (4) centrifugation, (5) Decolorization, deodorization, desalination, (6) concentrated drying step, the specific steps are as follows:

[0055] (1) Pretreatment: Weigh 20kg of fresh yak hide, chop it into 1×1cm blocks after depilation, add soda ash with a mass concentration of 5% at room temperature for 8 hours at a mass ratio of material to liquid of 1:5kg / kg, After soaking, wash the yak skin with water until it is neutral, then add the yak skin to the salt with a mass concentration of 5% at a mass ratio of 1:5kg / kg, and soak for another 8 hours. After the soaking, wash the yak skin with water Neutral to achieve the purpose of degreasing and removing impurities;

[0056] (2) Homogenization: add 0.05M acetic acid solution into 0.05M aceti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com