Ester organic reagent modified lithium-rich oxide positive electrode material as well as preparation method and application thereof

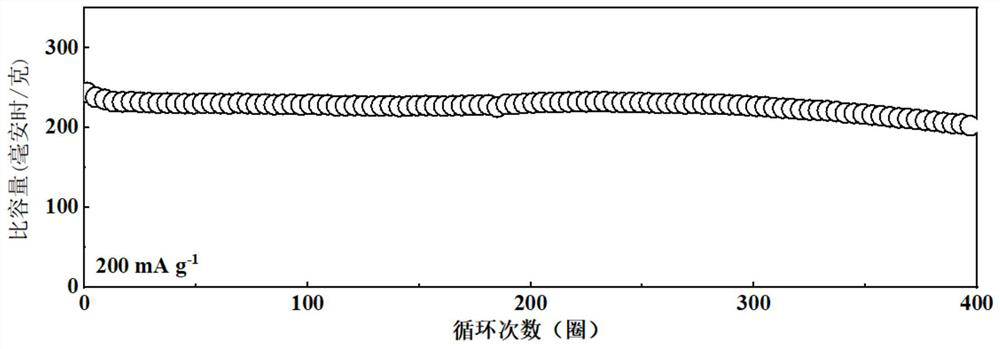

An organic reagent and modification technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve problems such as poor cycle performance, achieve high specific capacity, slow capacity decay, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

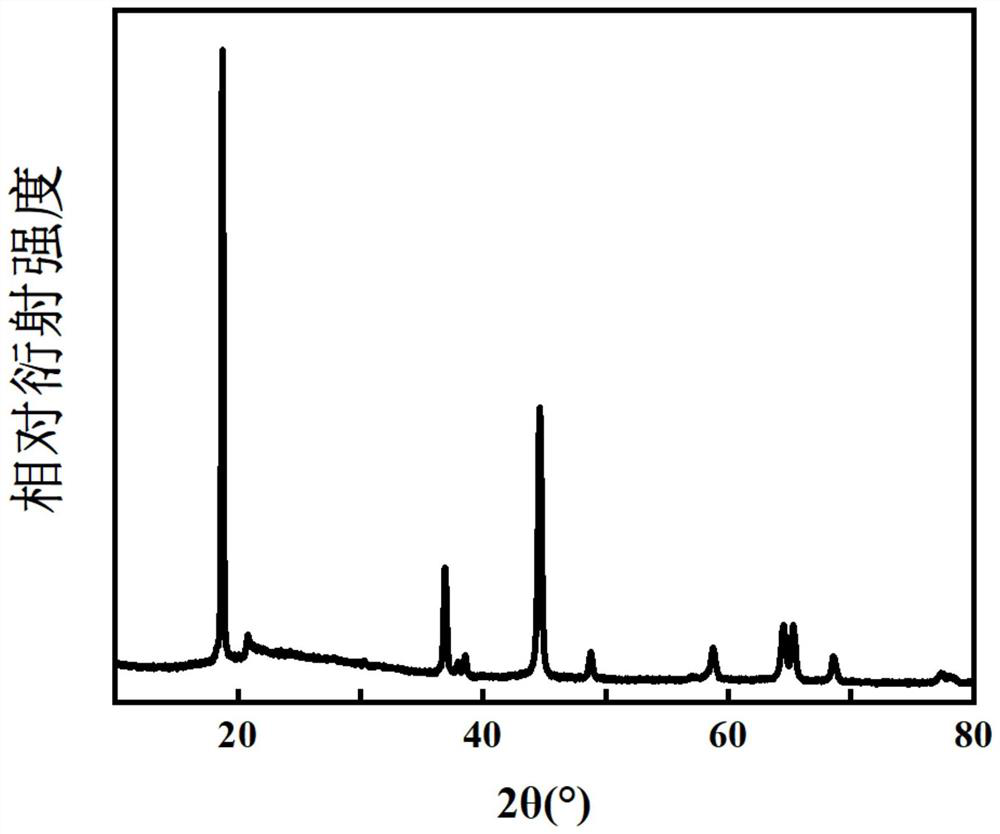

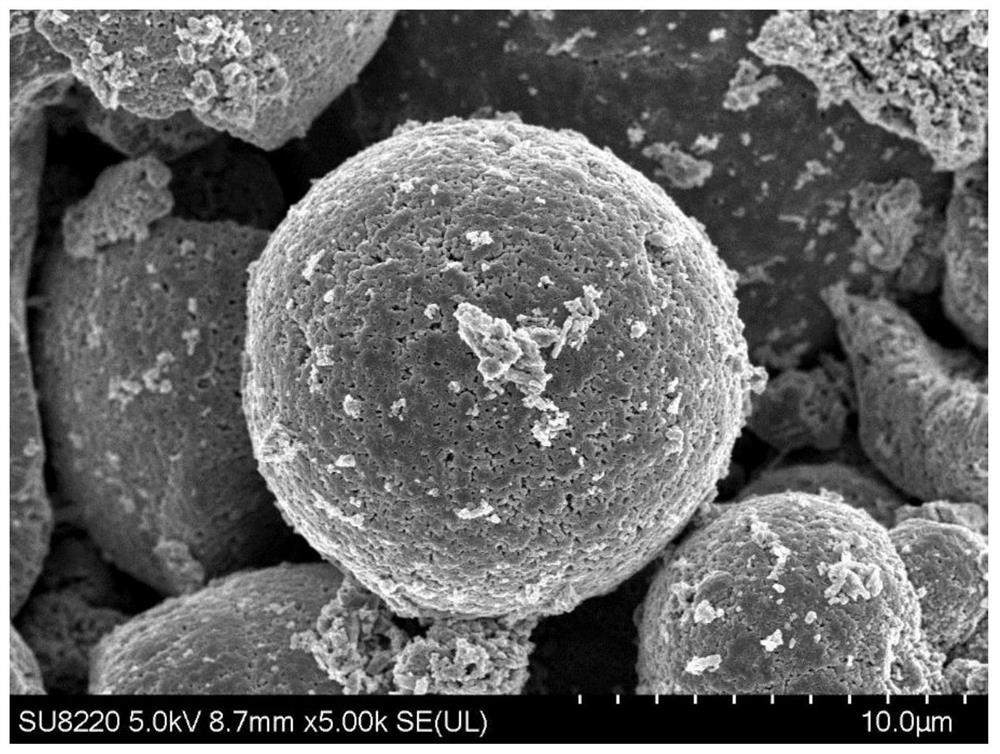

[0025] An embodiment of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent in the present invention, the chemical formula of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent is 0.2Li 2 MnO 3 -0.8LiMn 0.5 Ni 0.5 o 2 The preparation method of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent comprises the following steps:

[0026] (1) Weigh 0.96g transition metal carbonate microsphere precursor (Mn 0.75 Ni 0.25 CO 3 ) into a 100ml reaction kettle, and add 5ml of dimethyl carbonate in an argon atmosphere, after fully stirring, heat treatment in an oven at 150°C for 12h, cool with the furnace, and filter to obtain a powder;

[0027] (2) Add 0.4655g Lithium Carbonate, 1.8701g NaCl and 3.5784g KCl to the powder obtained in step (1), fully grind and then react in a box furnace at 850°C for 12h to complete the heat treatment and cool wit...

Embodiment 2

[0031]An embodiment of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent in the present invention, the chemical formula of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent is 0.2Li 2 MnO 3 -0.8LiMn 0.5 Ni 0.5 o 2 The preparation method of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent comprises the following steps:

[0032] (1) Weigh 0.96g transition metal carbonate microsphere precursor (Mn 0.75 Ni 0.25 CO 3 ) into a 100ml reaction kettle, and add 5ml of ethyl methyl carbonate in an argon atmosphere, after fully stirring, heat-treat in an oven at 100°C for 12h, cool with the furnace, and filter to obtain a powder;

[0033] (2) Add 0.4655g Lithium Carbonate, 1.8701g NaCl and 3.5784g KCl to the powder obtained in step (1), fully grind and then react in a box furnace at 850°C for 12h to complete the heat treatment and cool with...

Embodiment 3

[0036] An embodiment of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent in the present invention, the chemical formula of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent is 0.2Li 2 MnO 3 -0.8LiMn 0.5 Ni 0.5 o 2 The preparation method of the modified lithium-rich oxide positive electrode material modified by the ester organic reagent comprises the following steps:

[0037] (1) Weigh 0.96g transition metal carbonate microsphere precursor (Mn 0.75 Ni 0.25 CO 3 ) into a 100ml reaction kettle, and add 5ml of diethyl carbonate in an argon atmosphere, after fully stirring, heat-treat in an oven at 180°C for 12h, cool with the furnace, and filter to obtain a powder;

[0038] (2) Add 0.4655g Lithium Carbonate, 1.8701g NaCl and 3.5784g KCl to the powder obtained in step (1), fully grind and then react in a box furnace at 850°C for 12h to complete the heat treatment and cool with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com