Catalyst slurry for fuel cell, preparation method thereof and membrane electrode

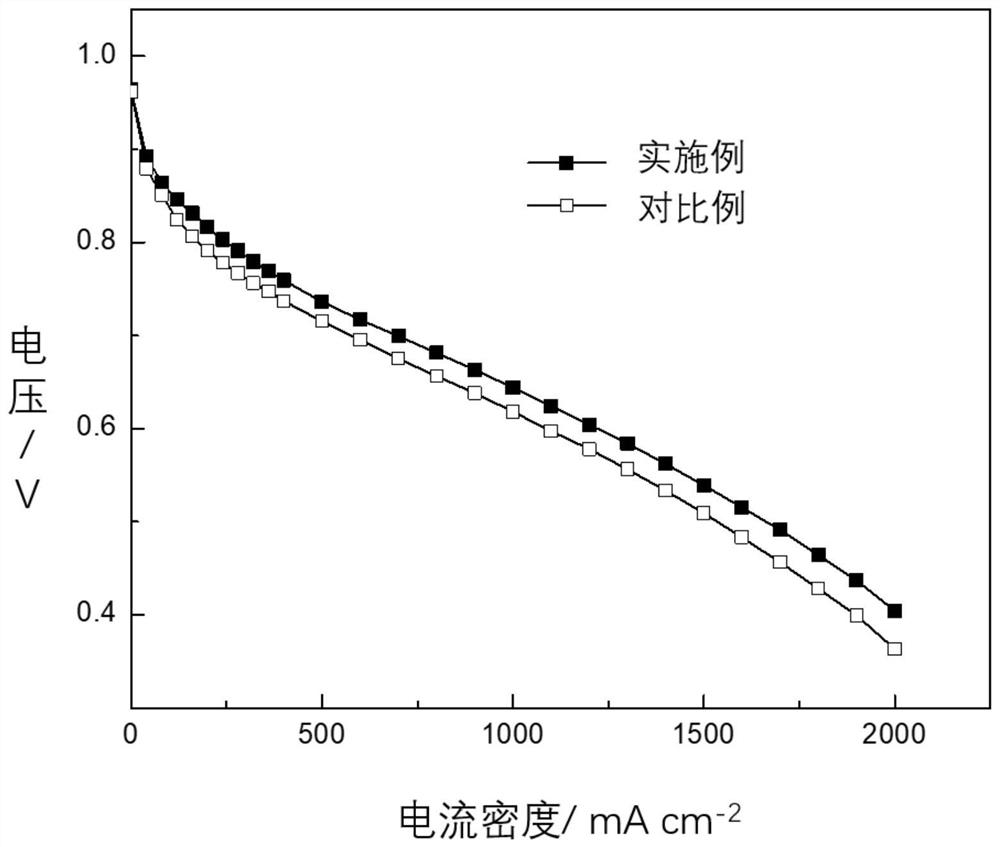

A catalyst slurry and fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problem of uneven dispersion of proton-conducting ionomers, achieve membrane electrode performance, avoid agglomeration, and increase battery voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a first aspect, the present application provides a method for preparing a fuel cell catalyst slurry, comprising the following steps:

[0027] Step S1) ultrasonically disperse the perfluorosulfonic acid solution at 50-90°C to obtain a perfluorosulfonic acid dispersion;

[0028] Step S2) mixing the perfluorosulfonic acid dispersion, the catalyst and the dispersion in deionized water to obtain the fuel cell catalyst slurry.

[0029] The preparation method of the catalyst slurry provided by this application can reduce the molecular size of the ionomer in the perfluorosulfonic acid solution by ultrasonically dispersing the perfluorosulfonic acid solution at a high temperature, and make the ionomer in the perfluorosulfonic acid solution The substance is fully dispersed to avoid its own agglomeration. Then, after mixing the perfluorosulfonic acid dispersion liquid treated with high-temperature ultrasonic treatment with catalyst, dispersant and deionized water, the ionomer ...

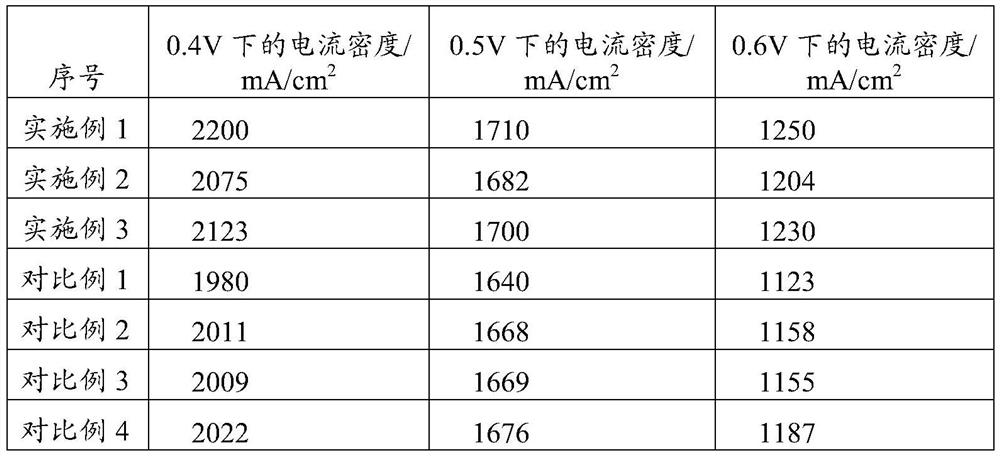

Embodiment 1

[0052] First add 18g of Nafion solution with a mass fraction of 5% to the container, add 50g of deionized water, and ultrasonically disperse at 90°C for 60min with an ultrasonic power of 600W; then add 3g of Pt / C catalyst particles with a Pt content of 60%, 75g of iso Propanol and 25 g of deionized water were dispersed with a Primix disperser at 10° C. for 10 minutes at a line speed of 25.5 m / s to make them evenly mixed to finally prepare a catalyst slurry.

[0053] Select the proton exchange membrane of Chemours model NC700, install it on the fixture, and install the fixture on the spraying equipment, spray the dispersed catalyst slurry on one side of the proton exchange membrane by ultrasonic spraying, and the spraying conditions are specific Yes: The heating temperature of the spraying table is 120-130°C, the linear speed of the nozzle is 100-120mm / s, and the liquid discharge speed is 0.8-1.0mL / min. Attach two pieces of gas diffusion layers to the proton exchange membrane c...

Embodiment 2

[0067] First add 18g of Nafion solution with a mass fraction of 5% to the container, add 50g of deionized water, and ultrasonically disperse at 60°C for 60min with an ultrasonic power of 600W; then add 3g of Pt / C catalyst particles with a Pt content of 60%, 75g of iso Propanol and 25 g of deionized water were dispersed with a Primix disperser at 10° C. for 10 minutes at a line speed of 25.5 m / s to make them evenly mixed to finally prepare a catalyst slurry.

[0068] Select the proton exchange membrane of Chemours model NC700, install it on the fixture, and install the fixture on the spraying equipment, spray the dispersed catalyst slurry on one side of the proton exchange membrane by ultrasonic spraying, and the spraying conditions are specific Yes: The heating temperature of the spraying table is 120-130°C, the linear speed of the nozzle is 100-120mm / s, and the liquid discharge speed is 0.8-1.0mL / min. Attach two pieces of gas diffusion layers to the proton exchange membrane c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com