LD multispectral exposure method and system for solder mask circuit integrated exposure

An exposure method and exposure system technology, applied in the field of LD multi-spectral exposure method and system for integrated exposure of solder resist lines, can solve problems such as loss of gloss on the surface of solder resist boards, and achieve system depth of field, high laser monochromaticity, good exposure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

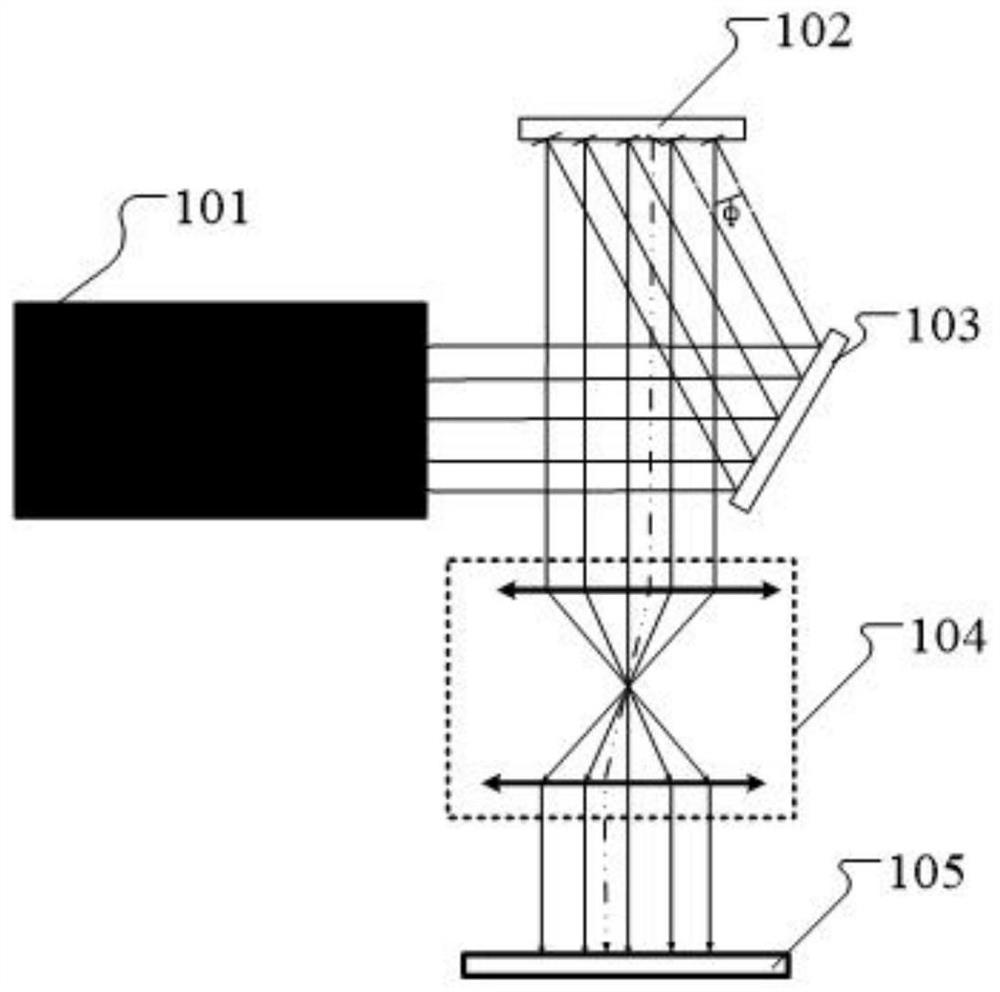

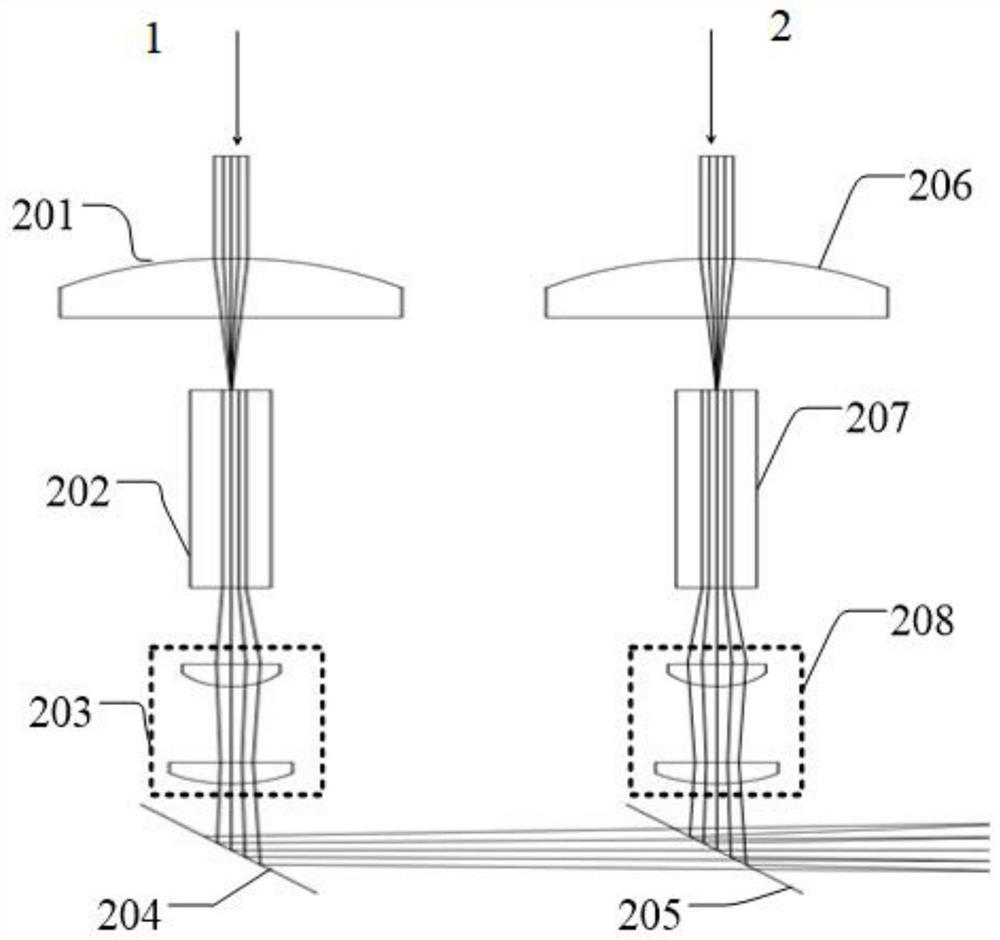

[0025] Embodiment 1: An LD multispectral exposure system for integrated exposure of solder resist lines, such as figure 1 As shown, it includes a combined light illumination system 101 that combines several light sources with different wavelengths, a spatial light modulator 102, a redirection element, and a wide-spectrum imaging system 104. In this embodiment, the above-mentioned redirection element is preferably a reflective The mirror 103 can also be set as other devices that change the direction of light propagation, such as reflective prisms, etc. The above-mentioned light-combining lighting system 101 is used to combine two LD lights of different wavelengths to combine light, and the light passing through the light-combining lighting system 101 Reflected by the mirror 103 to the spatial light modulator 102 , the spatial light modulator 102 converts the digital signal into an optical signal and projects it through graphic modulation, and then forms an image on the exposure ...

Embodiment 2

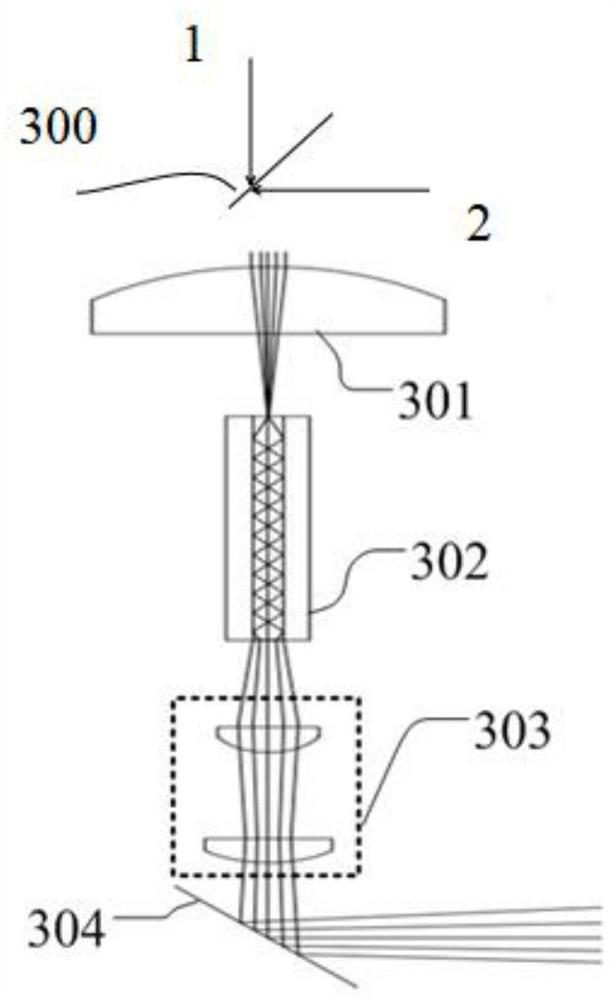

[0028] Embodiment 2: The difference with Embodiment 1 is that, as image 3 As shown, in this embodiment, the combined light illumination system 101 sequentially includes a dichroic filter 300, a third coupling element 301, a third light homogenizing element 302, a third focusing shaping mirror group 303, and a third dichroic mirror from the light source path. 304, the first light source 1 and the second light source 2 combine light through the dichroic filter 300 to form a multi-wavelength mixed light source, after being coupled by the third coupling member 301, it enters the third light homogenizing member 302, passes through the third The mixed light from the homogenizing element 302 forms a complete illumination spot after the third focusing and shaping mirror group 303, and irradiates on the third beam splitter 304, and the third beam splitter 304 that changes the light propagation route can be selected according to the needs in the optical path process According to the di...

Embodiment 3

[0029] Embodiment 3: The difference with Embodiment 1 and Embodiment 2 is that, as Figure 4 As shown, in this embodiment, the combined light illumination system 101 includes a first optical fiber, a second optical fiber and a fourth focusing shaping mirror group 402, the first light source 1 is incident into the first optical fiber, and the second light source 2 is incident into the second In the optical fiber, the first light source 1 and the second light source 2 are respectively coupled and combined by optical fiber to complete the light uniformity and shaping process, and are directly processed at the optical fiber outlet 401 to form the desired shape, and then formed by the fourth focusing and shaping mirror group 402 to form an ideal The lighting spot is enough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com