Hot-filled PET bottled sucrose-free nut milk and preparation method thereof

A sucrose-free, hot-filling technology, applied in the field of dairy products, can solve the problems of low-temperature-resistant PET packaging, high post-sterilization temperature, and small market share, so as to help gastrointestinal absorption, promote intestinal absorption, and improve intestinal absorption environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

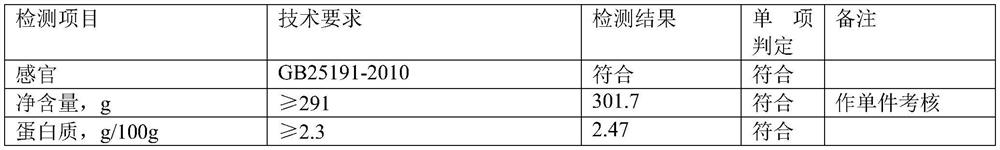

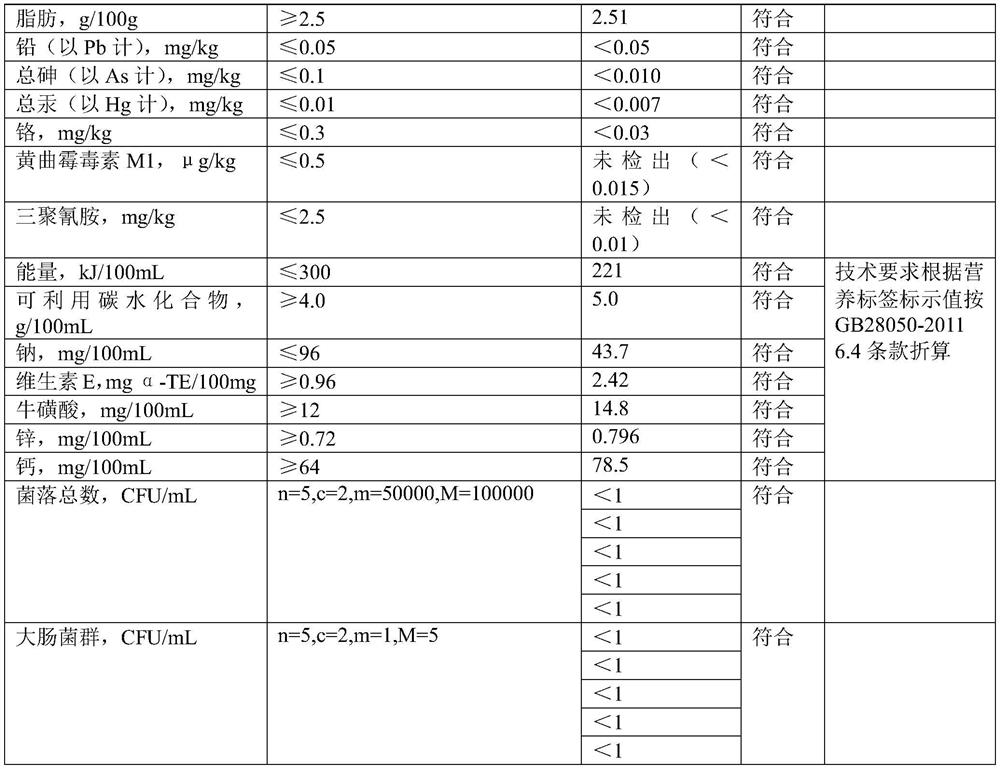

Embodiment 1

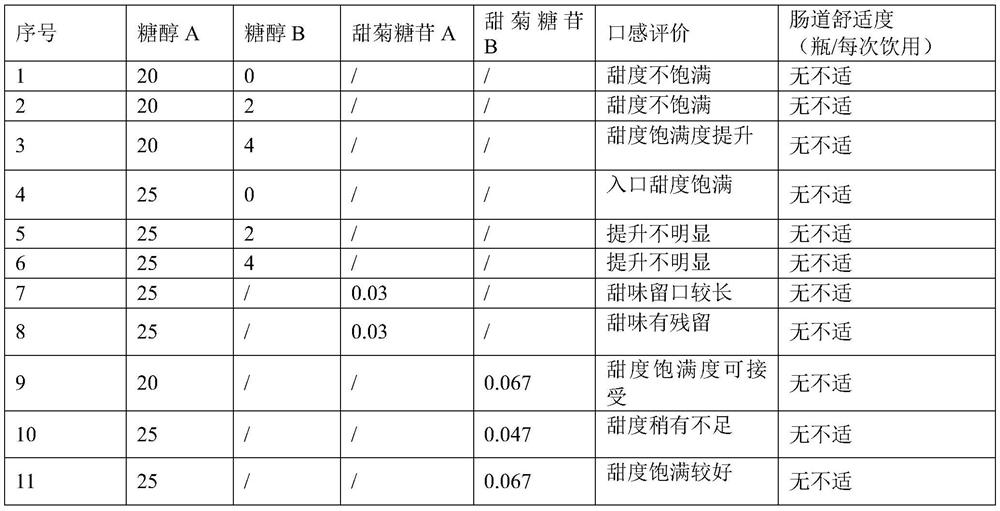

[0048] A hot-fill PET bottle of sucrose-free nut milk, the dosage of each component in every 1000ml drink is as follows: protein material (77.5 grams of whole milk powder, 20 grams of skimmed milk powder) 97.5 grams, 30 grams of healthy sugar (xylitol), black 2 grams of buckwheat tea, 5 grams of vegetable oil (coconut oil), 1 gram of nut butter (0.2 grams of peanut butter, 0.2 grams of pistachio butter, 0.2 grams of hazelnut butter, 0.2 grams of walnut butter, 0.2 grams of almond butter), 1.2 grams of emulsifier (0.9 grams of glyceryl monostearate, 0.3 grams of sucrose fatty acid ester), 0.8 grams of stabilizers (0.3 grams of carrageenan, 0.5 grams of gellan gum), 0.3 grams of antioxidants (0.1 grams of natural vitamin E, 0.2 grams of sodium erythorbate gram), acidity regulator 1 gram (sodium tripolyphosphate 0.5 gram, sodium bicarbonate 0.5 gram), nisin 0.15 gram, vitamin (vitamin E) 0.05 gram, mineral matter (zinc citrate 0.02 gram, taurine 0.2 g) 0.22 g, and the balance is ...

Embodiment 2

[0058] A hot-fill PET bottled sucrose-free nut milk, the dosage of each component in every 1000ml drink is as follows: 98.5 grams of protein material (80 grams of whole milk powder, 18.5 grams of skimmed milk powder), 10 grams of vegetable oil (sunflower oil), nut butter 1 gram (0.2 grams of peanut butter, 0.2 grams of pistachio butter, 0.2 grams of hazelnut butter, 0.2 grams of walnut butter, 0.2 grams of almond butter), 15.05 grams of healthy sugar (15 grams of xylitol, 0.05 grams of glucosyl steviol glycoside), black 2 grams of tartary buckwheat tea, 2 grams of emulsifier (1.0 grams of glyceryl monostearate, 1.0 grams of diacetyl tartaric acid mono- and diglycerides), 1.35 grams of stabilizer (0.35 grams of carrageenan, 1.0 grams of microcrystalline cellulose), acidity Regulator 1.1g (sodium tripolyphosphate 0.5g, sodium citrate 0.2g, sodium bicarbonate 0.4g), antioxidant (sodium erythorbate) 0.25g, nisin 0.15g, vitamin (vitamin E) 0.063g, 0.22 grams of minerals (0.02 grams...

Embodiment 3

[0068] A hot-fill PET bottled sucrose-free nut milk, the dosage of each component in every 1000ml drink is as follows: 99 grams of protein raw materials (70 grams of whole milk powder, 26 grams of skimmed milk powder, 3 grams of concentrated milk protein), 8 grams of cream, Nut butter 1.45g (peanut butter 0.25g, pistachio butter 0.2g, hazelnut butter 0.25g, walnut butter 0.25g, almond butter 0.25g, chestnut butter 0.25g), healthy sugar 15.15g (erythritol 15g, glucose 0.15 grams of steviol glycosides), 5 grams of black tartary buckwheat tea, 2 grams of emulsifiers (0.8 grams of glyceryl monostearate, 1.2 grams of diacetyl tartrate mono-diglycerides), 2.65 grams of stabilizers (0.35 grams of carrageenan, micro Crystalline cellulose 2.3 grams), antioxidant 0.25 grams (natural vitamin E 0.1 grams, sodium erythorbate 0.15 grams), acidity regulator 1.1 grams (sodium tripolyphosphate 0.5 grams, sodium bicarbonate 0.6 grams), nisin 0.15 grams gram, vitamin (vitamin E) 0.05 gram, miner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com