Iron-cobalt-tantalum alloy powder preparation method, iron-cobalt-tantalum alloy powder, and application

A tantalum alloy and iron-cobalt technology, applied in the field of alloy powder preparation, can solve the problems of easy clogging of pipelines, failure of gas atomization, and obstacles in the preparation and research and development of Fe-Co alloy sputtering targets, so as to prevent clogging, The effect of preventing pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

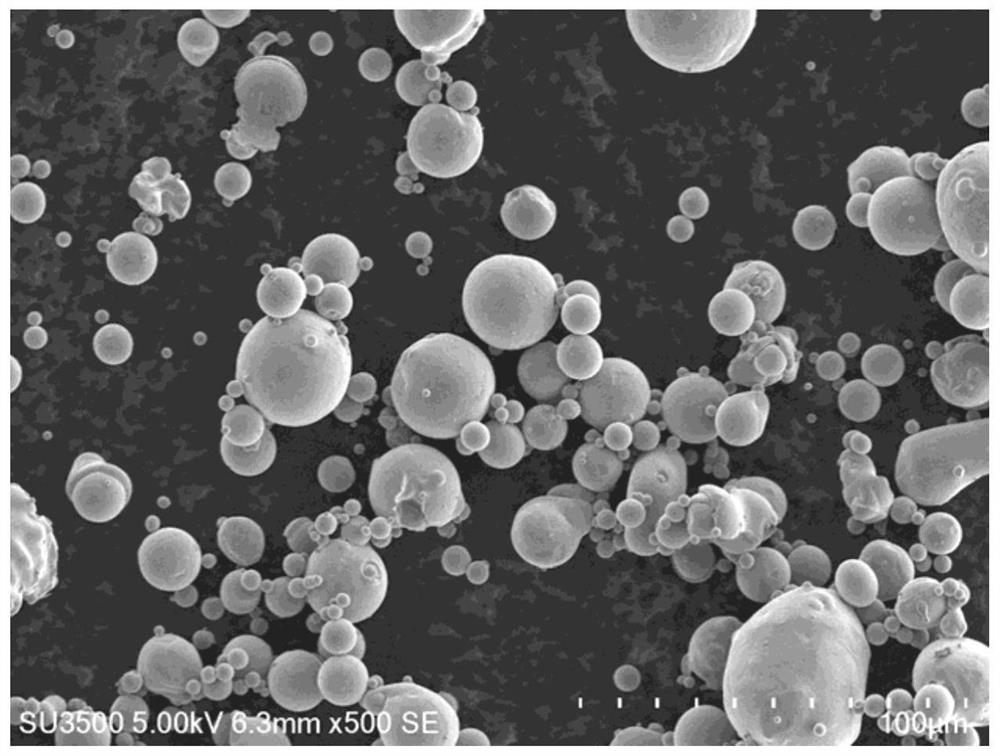

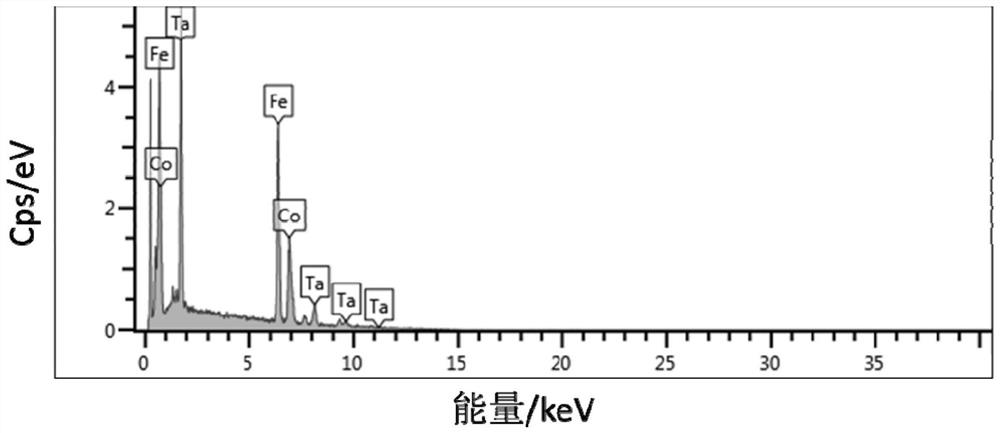

Image

Examples

Embodiment 1

[0071] This embodiment provides a method for preparing iron-cobalt-tantalum alloy powder, the preparation method comprising the following steps:

[0072] (1) degreasing, pickling, drying and vacuum packaging the electrolytic iron material with a purity of ≥99.95%, the electrolytic cobalt material with a purity of ≥99.95%, and the tantalum scrap (purity ≥99.95%) disclosed in CN102517531A The preprocessing of:

[0073] First put the electrolytic iron material, electrolytic cobalt material and tantalum side material into an aqueous solution containing detergent, ultrasonically clean at 60°C for 60 minutes for degreasing treatment, then rinse and wipe clean with pure water; Ultrasonic cleaning in the washing solution for 20 minutes to carry out pickling, in terms of mass percentage, nitric acid in the pickling solution is 38.5%, hydrofluoric acid is 7.1%, then rinse with pure water and wipe clean; The electrolytic iron material, electrolytic cobalt material and tantalum side mate...

Embodiment 2

[0081] This embodiment provides a method for preparing iron-cobalt-tantalum alloy powder, except that "control absolute vacuum degree ≤ 10Pa" in step (2) is replaced by "control absolute vacuum degree fluctuates between 12-15Pa", other conditions Exactly the same as Example 1.

Embodiment 3

[0083] This example provides a method for preparing iron-cobalt-tantalum alloy powder, except that the "pressure is 3.5MPa" in step (3) is replaced with "pressure is 2.5MPa", other conditions are exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com