ZrO2-based conductive ceramic and preparation method thereof

A technology of conductive ceramics and conductive materials, which is applied in the field of preparation of conductive ceramic materials, can solve the problems of difficult sintering and densification, high sintering temperature, and high sintering cost, and achieve the goals of reducing sintering temperature, improving stability, and improving compactness and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

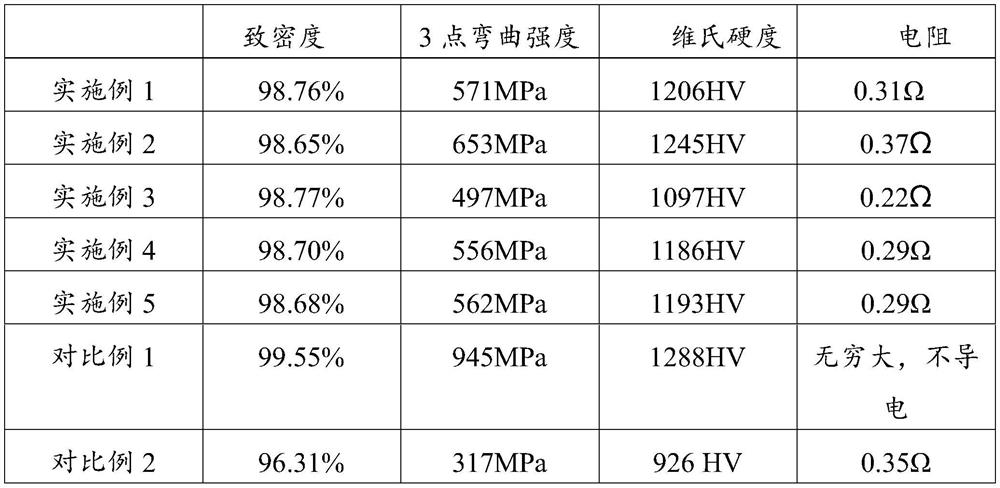

Examples

Embodiment 1

[0028] a ZrO 2 The preparation method of base conductive ceramics, its step comprises:

[0029] (1) Put 65 copies of Y 2 o 3 Stabilized ZrO 2 Powder, 40 parts of TiN, 5 parts of Si powder, 0.5 parts of polyethylene glycol, 1 part of ammonium polyacrylate, 1 part of polyvinyl alcohol and 100 parts of water were added to the ball mill jar for ball milling, ZrO 2 The ball was used as the ball milling medium, and the ball was milled for 6 hours to obtain the slurry;

[0030] (2) The slurry is sprayed and granulated in a spray dryer, the inlet temperature is 250°C, the outlet temperature is 140°C, the feed frequency is 18HZ, and the atomization frequency is 24HZ to obtain powder A;

[0031] (3) Pass powder A through a 80-mesh sieve, take the powder under the sieve and pass through a 240-mesh sieve, and take the powder on the sieve to obtain powder B of 80-240 mesh;

[0032] (4) Carry out dry pressing molding to the powder material B that step (3) makes under the condition of 5...

Embodiment 2

[0035] a ZrO 2 The preparation method of base conductive ceramics, its step comprises:

[0036] (1) Put 70 copies of Y 2 o 3 Stabilized ZrO 2 Powder, 30 parts of TiC, 4 parts of Co powder, 2 parts of polyethylene glycol, 1.5 parts of ammonium polyacrylate, 0.8 parts of polyvinyl alcohol and 120 parts of water were added to the ball mill jar for ball milling, ZrO 2 The ball was used as the ball milling medium, and the ball was milled for 8 hours to obtain the slurry;

[0037] (2) The slurry is sprayed and granulated in a spray dryer, the inlet temperature is 280°C, the outlet temperature is 120°C, the feed frequency is 20HZ, and the atomization frequency is 22HZ to obtain powder A;

[0038] (3) Pass powder A through a 80-mesh sieve, take the powder under the sieve and pass through a 240-mesh sieve, and take the powder on the sieve to obtain powder B of 80-240 mesh;

[0039] (4) Carry out dry pressing molding to the powder material B that step (3) makes under the condition ...

Embodiment 3

[0042] a ZrO 2 The preparation method of base conductive ceramics, its step comprises:

[0043](1) Put 80 copies of Y 2 o 3 Stabilized ZrO 2 Powder, 10 parts of TiN, 30 parts of TiB 2 , 20 parts of TiC, 8 parts of Al powder, 1.6 parts of polyethylene glycol, 1.2 parts of ammonium polyacrylate, 0.6 parts of polyvinyl alcohol and 90 parts of water are added to the ball mill jar for ball milling, ZrO 2 The ball was used as the ball milling medium, and the ball was milled for 10 hours to obtain the slurry;

[0044] (2) The slurry is sprayed and granulated in a spray dryer, the inlet temperature is 300°C, the outlet temperature is 110°C, the feed frequency is 18HZ, and the atomization frequency is 20HZ to obtain powder A;

[0045] (3) Pass powder A through a 80-mesh sieve, take the powder under the sieve and pass through a 240-mesh sieve, and take the powder on the sieve to obtain powder B of 80-240 mesh;

[0046] (4) Carry out dry pressing molding to the powder material B th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com