Method for manufacturing passenger dedicated line railway turnout sliding platen with high-speed laser cladding surface

A technology for laser cladding and passenger dedicated lines, which is applied in the direction of rails, roads, coatings, etc., can solve the problems of low cladding work efficiency, large waste of substrate materials and welding materials, rough coating surface, etc., to meet large-scale The effect of production needs, high cladding work efficiency, and small coating dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for manufacturing a general-purpose sliding bed and a roller sliding bed for high-speed laser cladding of a passenger-dedicated line railway turnout, the specific steps are as follows:

[0042] 1. The preparation and surface treatment of the base of the universal sliding bed and roller sliding bed:

[0043] The base body of the universal sliding table and the roller sliding table is prepared by casting or forging,

[0044] Use the sandblasting method to derust and degrease the base surface of the universal sliding bed and roller sliding bed,

[0045] 2. Requirements for chemical composition and appearance quality of Fe-based alloy powder:

[0046] Chemical composition mass percentage: Cr 13, Ni 20, Mo 1.0, Mn0.5, Si<3.5, B<2.5, C0.1-0.25, P≤0.045, S≤0.035, Fe balance.

[0047] Appearance quality: particle size 15μm, sphericity > 90%, fluidity < 20s / 50g.

[0048] 3. The cladding process is as follows:

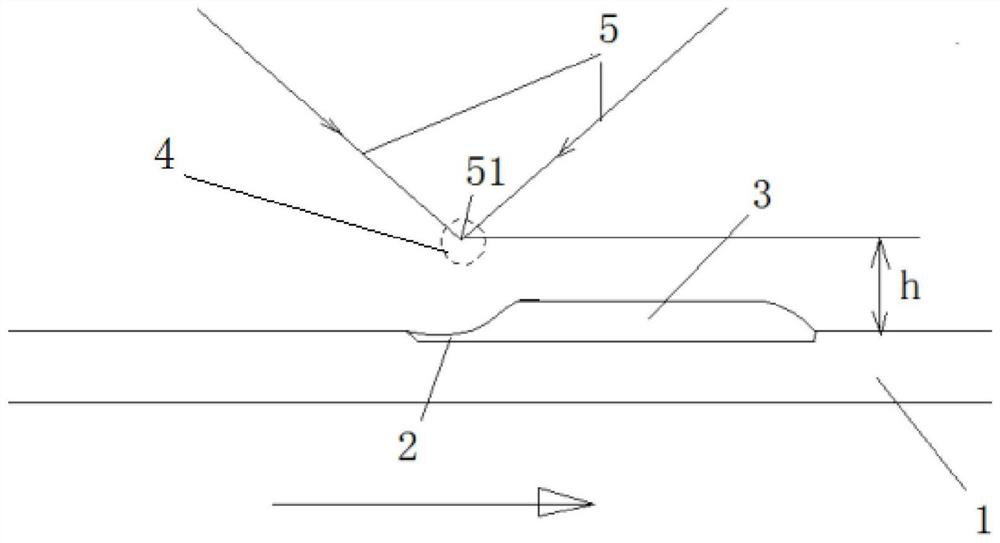

[0049] Such as figure 1 As shown, the position of the ...

Embodiment 2

[0073] The difference between embodiment 2 and embodiment 1 only lies in the following:

[0074] Requirements for chemical composition and appearance quality of Fe-based alloy powder:

[0075] Chemical composition mass percentage: Cr 20, Ni 10, Mo 0.75, Mn1.0, Si<3.5, B<2.5, C0.1-0.25, P≤0.045, S≤0.035, Fe balance.

[0076] Appearance quality: particle size 50μm, sphericity > 90%, fluidity < 20s / 50g.

[0077] Final product performance: coating thickness: ≥1.21mm, surface hardness: HB≥350,

[0078] Surface corrosion resistance: NSS≥60h;

Embodiment 3

[0080] The difference between embodiment 3 and embodiment 1 only lies in the following:

[0081] Requirements for chemical composition and appearance quality of Fe-based alloy powder:

[0082] Chemical composition mass percentage: Cr 16, Ni 30, Mo 0.5, Mn0.75, Si<3.5, B<2.5, C0.1-0.25, P≤0.045, S≤0.035, Fe balance.

[0083] Appearance quality: particle size 30μm, sphericity > 90%, fluidity < 20s / 50g.

[0084] Final product performance: coating thickness is 1.2mm, surface hardness: 350-356HB,

[0085] Surface corrosion resistance: NSS≥60h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com