Composite photocatalyst film as well as preparation method and application thereof

A catalyst and composite light technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low sunlight utilization rate, reduced catalytic activity, unfavorable reuse, etc. Catalytic efficiency, increasing the illuminated area, and reducing the effect of electron-hole recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

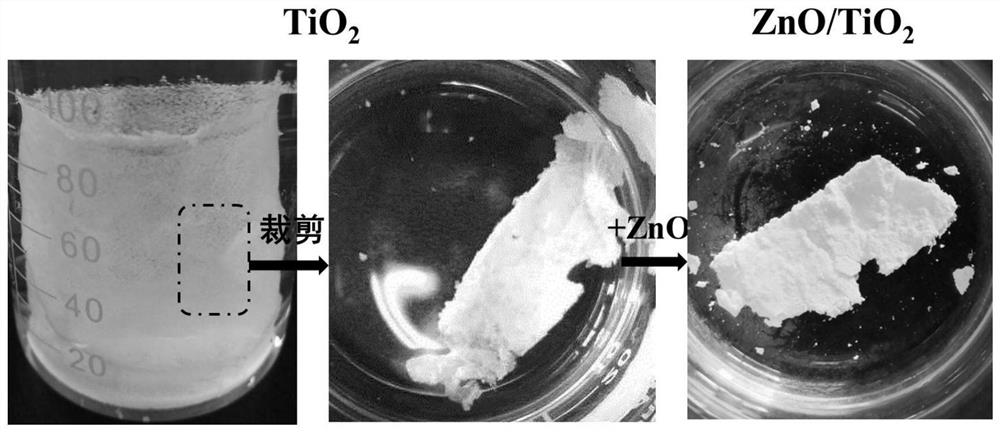

[0036] The present invention also provides a method for preparing the composite photocatalyst film described in the above technical solution, comprising the following steps:

[0037] A titanium dioxide film is provided, the titanium dioxide film is formed by interweaving titanium dioxide nanowires;

[0038] adding the zinc salt solution to the alkali solution to obtain a zinc oxide precursor solution;

[0039] immersing the titanium dioxide film in a zinc oxide precursor solution, and self-assembling to obtain the composite photocatalyst film;

[0040] The molar ratio of the titanium element in the titanium dioxide nanowire to the zinc element in the zinc oxide precursor solution is 4-12:1.

[0041] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0042] In the present invention, the preparation method of the titanium dioxide film comprises the following steps:

[0043] Afte...

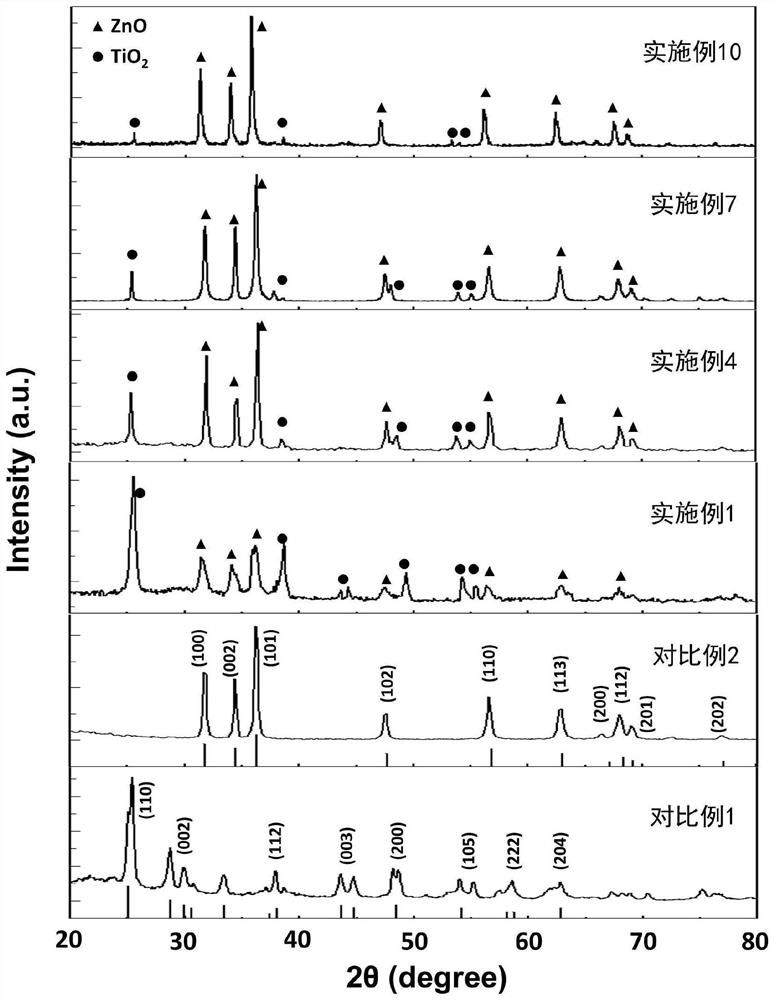

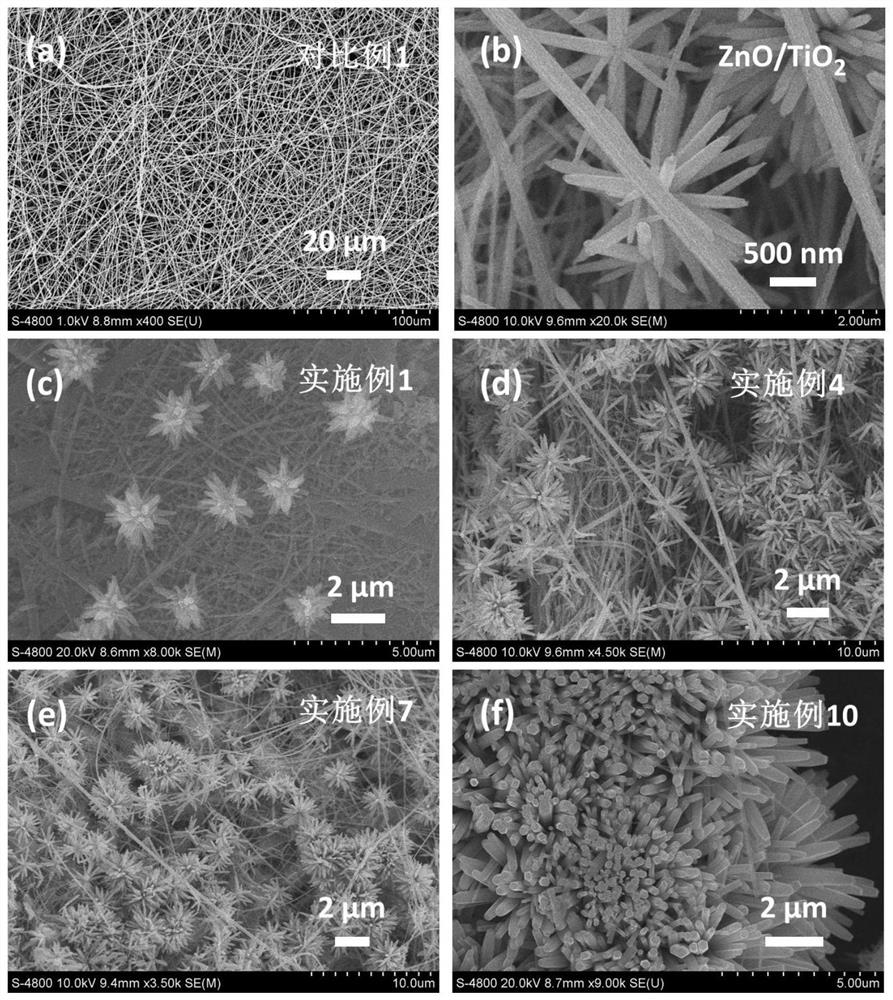

Embodiment 1

[0073] Ultrasonicate 0.14g tetra-n-butyl titanate and 15mL deionized water at a power of 100W for 15min to obtain Ti(OH) 4 colloid;

[0074] The Ti(OH) 4 The colloid and 20mL10mol / L sodium hydroxide solution were sonicated for 15min at a power of 100W to obtain 35mL sodium titanate film precursor solution;

[0075] Transfer the sodium titanate film precursor solution to a 50mL autoclave with a polytetrafluoroethylene liner, and react at 200°C for 48h to obtain a sodium titanate film; the linear titanium in the sodium titanate film The diameter of sodium bicarbonate is 70-80nm, and the aspect ratio is 500-600:1;

[0076] Rinse the sodium titanate film from the surface of the polytetrafluoroethylene liner with deionized water and soak it in a hydrochloric acid solution with a concentration of 0.1 mol / L for 24 hours to obtain a titanate film;

[0077] Soak and wash the phthalic acid film in deionized water for 40 minutes, and repeat the soaking and washing 4 times; use a dropp...

Embodiment 2

[0085] Composite photocatalyst film is prepared according to the preparation method of embodiment 1, the difference is that Zn(NO 3 ) 2 The solution was replaced by Zn(CH 3 COO) 2 solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com