Production process of degradable packaging paper and production equipment

A production process and production equipment technology, applied in the field of degradable packaging paper production process and production equipment, can solve problems such as inability to convey downwards, and achieve the effects of good melting effect, improved mechanical strength, improved air permeability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

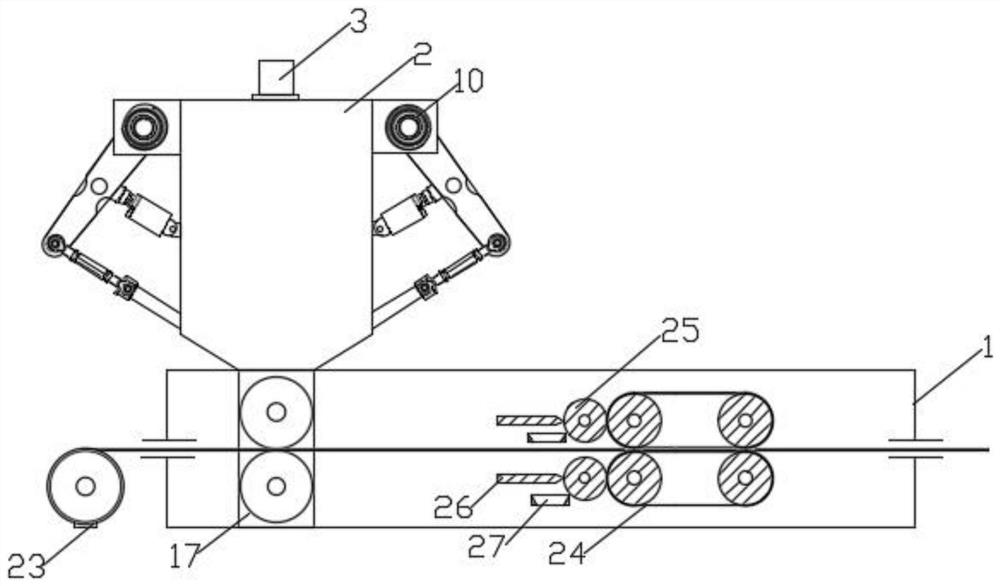

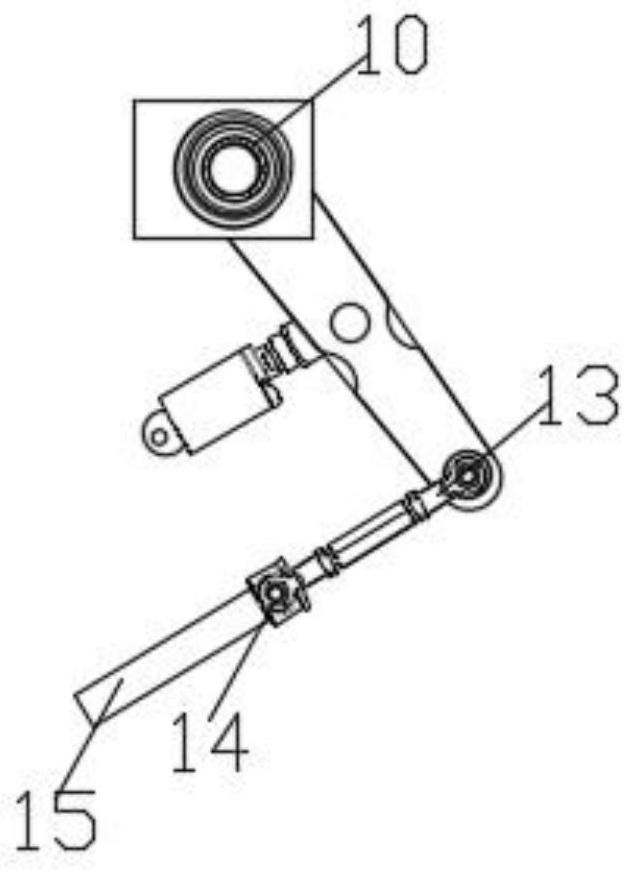

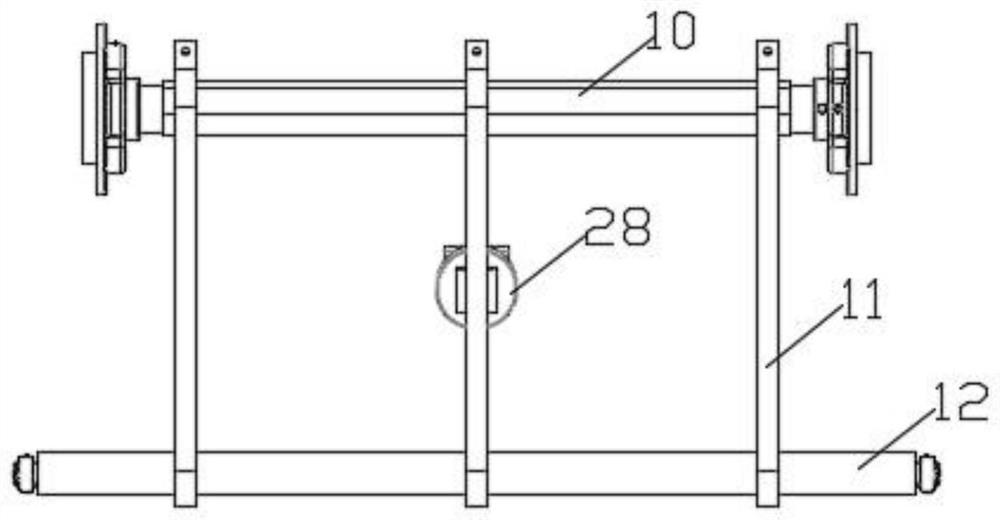

Method used

Image

Examples

Embodiment 1

[0034] A production process of degradable wrapping paper, comprising the steps of:

[0035] Step 1: In parts by weight, weigh 4 parts of konjac glucomannan, 8 parts of carrageenan, and 8 parts of soybean protein isolate, and dissolve the konjac glucomannan, carrageenan, and soybean protein isolate in 1L of water, and stir evenly And let stand to swell for 2h, then get konjac sol;

[0036] Step 2: take food-grade raw wood pulp and water for melting, and use 0.1mol / L sodium hydroxide to adjust the pH to 7.5, and prepare food-grade wood pulp;

[0037] Step 3: In the konjac sol of step 1, add glycerin accounting for 0.3% of the konjac sol weight as a plasticizer, and add the food-grade wood pulp prepared by step 2 by 2.5 times the weight of the konjac sol, and utilize a mixer under a 70°C water bath Stir, adjust the viscosity of the sol with 5% modified starch solution to make the viscosity not less than 600Pa·s, adjust the pH of the sol to 8.0 with 0.1mol / L sodium hydroxide or s...

Embodiment 2

[0042] A production process of degradable wrapping paper, comprising the steps of:

[0043] Step 1: In parts by weight, weigh 8 parts of konjac glucomannan, 10 parts of carrageenan, and 10 parts of soybean protein isolate, and dissolve konjac glucomannan, carrageenan, and soybean protein isolate in 1L of water, and stir evenly And let stand to swell for 3h, then get konjac sol;

[0044] Step 2: Take food-grade raw wood pulp and water for melting, and use 0.1mol / L sodium hydroxide to adjust the pH to 8.5, and prepare food-grade wood pulp;

[0045] Step 3: In the konjac sol of step 1, add glycerin accounting for 0.5% of the konjac sol weight as a plasticizer, and add the food-grade wood pulp prepared by step 2 by 3.5 times the weight of the konjac sol, and use a mixer under 85 ° C water bath Stir, adjust the viscosity of the sol with 20% modified starch solution to make the viscosity not less than 600Pa·s, adjust the pH of the sol to 9.5 with 0.1mol / L sodium hydroxide or sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com