A matt coating with a soft, smooth touch

A smooth and coating technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of high hardness, poor transparency, etc., to meet the requirements of temperature resistance and scratch resistance, good transparency, good adhesion and The effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

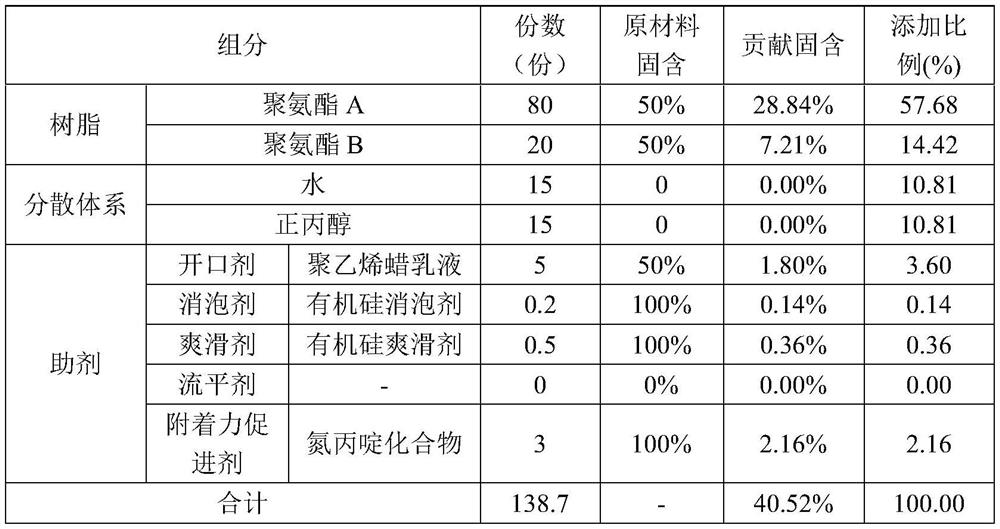

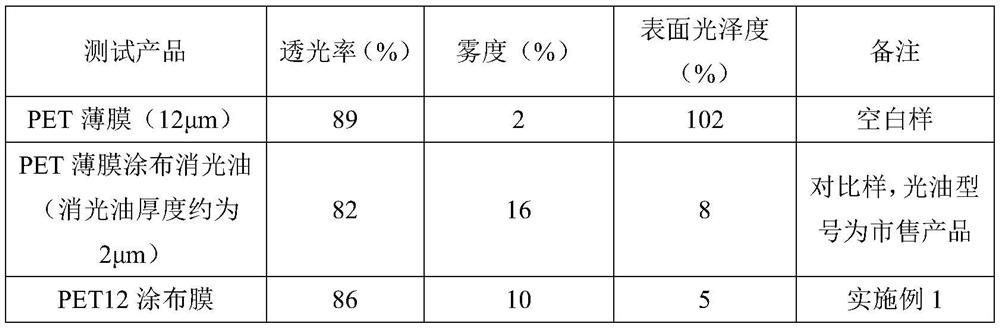

[0054] A matte coating with a soft and smooth touch, which is obtained by coating the coating solution on a film and drying it. The added parts by weight, raw material information and addition ratio are as shown in Table 1. The amount of components in Example 1

[0055] The component consumption of the coating liquid of table 1 embodiment 1

[0056]

[0057] Among the above components, polyurethane A is a white aqueous dispersion with a glass transition temperature of 10°C and 36°C, a primary particle size of 0.6-1 μm, and a solid content of 50%;

[0058] Polyurethane resin B is a translucent white aqueous dispersion with a glass transition temperature of 18° C., a primary particle size of 0.3 μm, and a solid content of 50%.

[0059] The dispersion system is composed of water and n-propanol.

[0060] Among the additives, the anti-blocking agent polyethylene wax emulsion is a white water dispersion, its D50 particle size is 1.2 μm, and its solid content is 50%.

[0061] Mi...

Embodiment 2

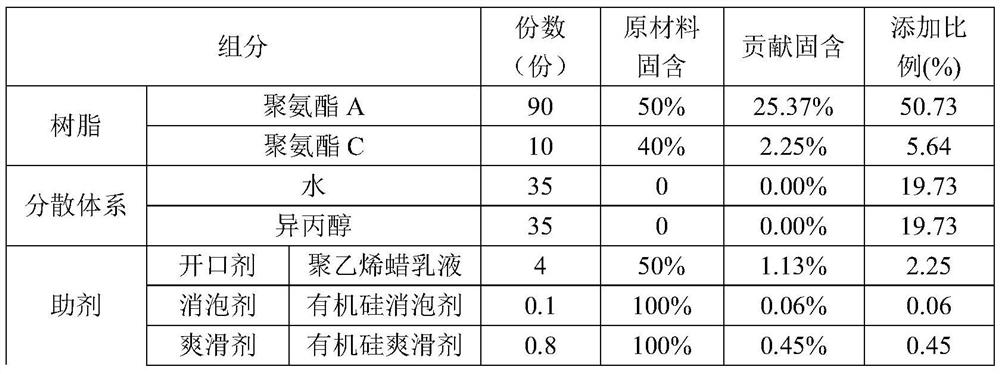

[0071] A matte coating with a soft and smooth touch, which is obtained by rolling the coating solution onto the film and drying it. The added parts by weight, raw material information and addition ratio are as shown in the component dosage of Example 2 in Table 3

[0072] The component consumption of the coating liquid of table 3 embodiment 2

[0073]

[0074]

[0075] Among the above components, polyurethane A is a white aqueous dispersion with a glass transition temperature of 10°C and 36°C, a primary particle size of 0.6-1 μm, and a solid content of 50%;

[0076] Polyurethane resin B is a translucent white aqueous dispersion with a glass transition temperature of 12°C, a primary particle size of 0.4 μm, and a solid content of 40%.

[0077] The dispersion system is composed of water and isopropanol.

[0078] Among the additives, the anti-blocking agent polyethylene wax emulsion is a white water dispersion, its D50 particle size is 1.2 μm, and its solid content is 50%....

Embodiment 3

[0089] A kind of matt coating with soft and smooth touch, which is obtained by coating the coating solution on a film and drying it. The added parts by weight, raw material information and addition ratio are as shown in the component dosage of Example 3 in Table 5

[0090] The component consumption of the coating liquid of table 5 embodiment 3

[0091]

[0092] Among the above components, polyurethane E is a white aqueous dispersion with a glass transition temperature of 16°C and 40°C, a primary particle size of 1.0-1.4μm, and a solid content of 40%;

[0093] Acrylic resin D is a translucent white aqueous dispersion with a glass transition temperature of 16°C, a primary particle size of 0.3 μm, and a solid content of 35%.

[0094] The dispersion system is composed of water and ethanol.

[0095] Among the additives, the anti-blocking agent polyethylene wax emulsion is a white water dispersion with a D50 particle size of 2.2 μm and a solid content of 40%; the mineral oil def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com