Lithium-rich manganese-based composite positive electrode material and preparation method and application thereof

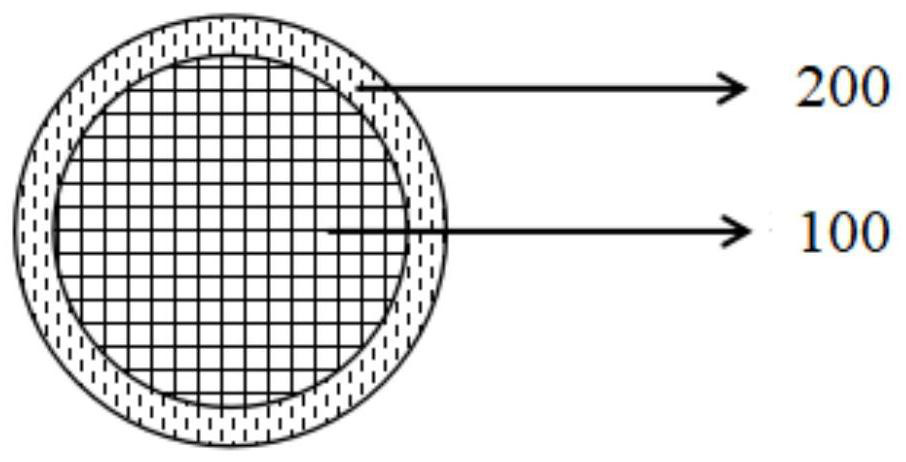

A composite positive electrode material, lithium-rich manganese-based technology, applied in the direction of positive electrodes, electrode manufacturing, battery electrodes, etc., can solve the low coulombic efficiency of lithium-rich manganese-based positive electrode materials for the first time, difficult to withstand cyclic working voltage, and hinder the commercialization process and other problems, to achieve the effect of stable cycle performance, high first-time efficiency, uniform and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

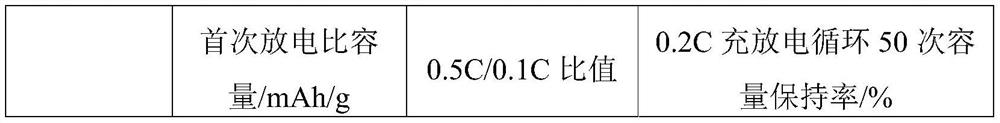

Embodiment 1

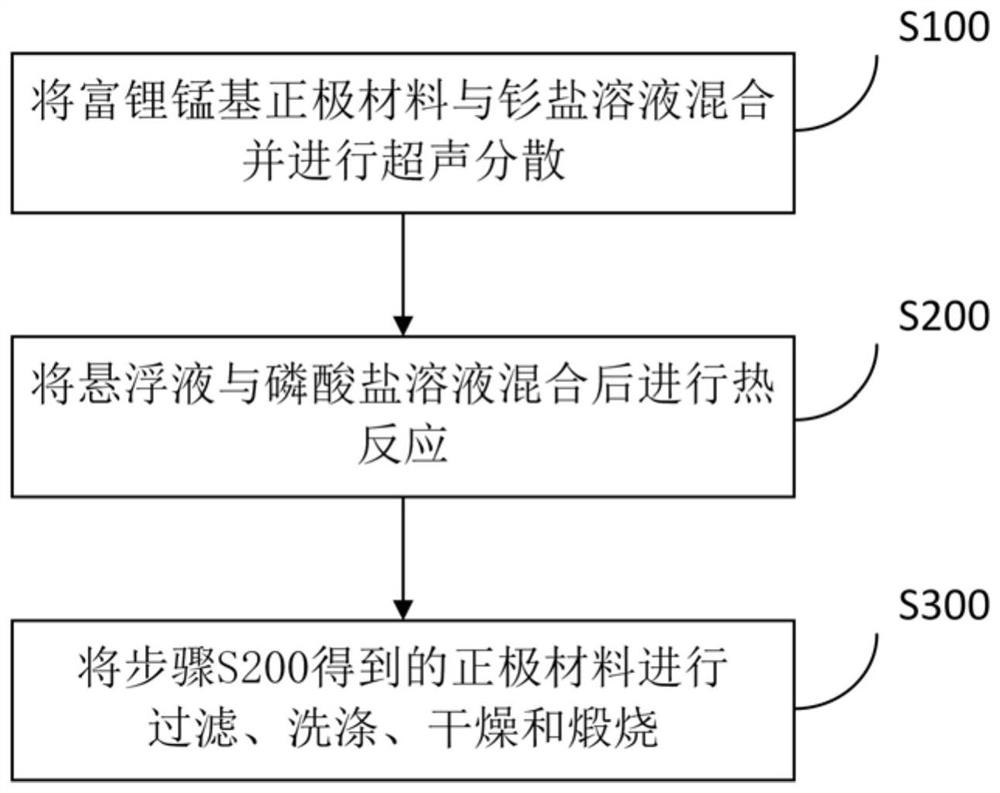

[0057] The method for preparing lithium-rich manganese-based positive electrode materials is as follows:

[0058] (1) The lithium-rich manganese-based cathode material (chemical formula xLi 2 MnO 3 (1-x)LiMO 2 , where M is the same molar ratio of Ni, Co, Mn metal elements, and x is 0.5. ) mixed with samarium nitrate solution (concentration: 0.1mol / L) and ultrasonically dispersed to obtain a suspension, the mass ratio of the lithium-rich manganese-based positive electrode material to the samarium salt solution was 1:30;

[0059] (2) Mix the suspension obtained above with NaH 2 PO 4 After the solution (concentration is 0.1mol / L) is mixed, it is supplied to a hydrothermal tank for thermal reaction (temperature is 140°C, time is 8h), in which NaH 2 PO 4 The molar ratio to samarium nitrate is 1.2:1, forming a preliminary coating layer on the surface of the positive electrode material;

[0060] (3) Filter, wash, dry and calcinate the positive electrode material obtained in st...

Embodiment 2

[0067] The method for preparing lithium-rich manganese-based positive electrode materials is as follows:

[0068] (1) The lithium-rich manganese-based cathode material (chemical formula xLi 2 MnO 3 (1-x)LiMO 2 , wherein M is the same molar ratio of Ni, Co, Mn metal elements, and x is 0.5) mixed with samarium nitrate solution (concentration is 0.05mol / L) and ultrasonically dispersed to obtain a suspension;

[0069] (2) Mix the suspension obtained above with (NH 4 ) 2 HPO 4 The solution (concentration is 0.15mol / L) is mixed and supplied to a hydrothermal tank for thermal reaction (temperature is 120°C, time is 6h), wherein (NH 4 ) 2 HPO 4 The molar ratio with samarium nitrate is 1:1, forming a preliminary coating layer on the surface of the positive electrode material;

[0070] (3) Filtrate, wash, dry and calcinate the positive electrode material obtained in step (2) (calcination temperature is 650 degrees Celsius, time is 8 hours), to obtain lithium-rich manganese-based...

Embodiment 3

[0077] The method for preparing lithium-rich manganese-based positive electrode materials is as follows:

[0078] (1) The lithium-rich manganese-based cathode material (chemical formula xLi 2 MnO 3 (1-x)LiMO 2 , where M is the same molar ratio of Ni, Co, Mn metal elements, and x is 0.5. ) mixed with samarium chloride solution (concentration is 0.1mol / L) and ultrasonically dispersed to obtain a suspension;

[0079] (2) Mix the suspension obtained above with NH 4 h 2 PO 4 The solution (concentration is 0.1mol / L) is mixed and supplied to a hydrothermal tank for thermal reaction (temperature is 120°C, time is 8h), in which NH 4 h 2 PO 4 The molar ratio to samarium chloride is 1:1, forming a preliminary coating layer on the surface of the positive electrode material;

[0080] (3) Filter, wash, dry and calcinate the positive electrode material obtained in step (2) (calcination temperature is 500 degrees Celsius, time is 12 hours), to obtain lithium-rich manganese-based comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com