Silver/bismuth vanadate/carbon nitride heterojunction photocatalyst as well as preparation method and application thereof

A photocatalyst and carbon nitride technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of poor carrier separation efficiency and photogenerated electron-hole recombination rate Advanced problems, to achieve the effect of high degradation rate and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

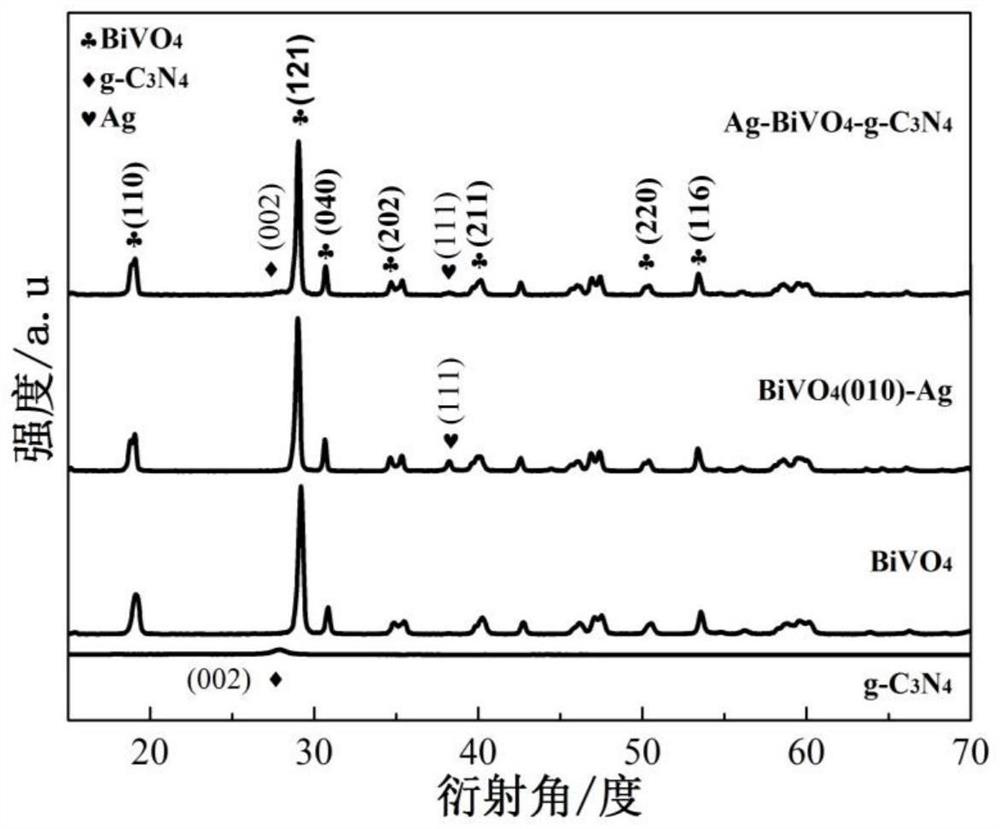

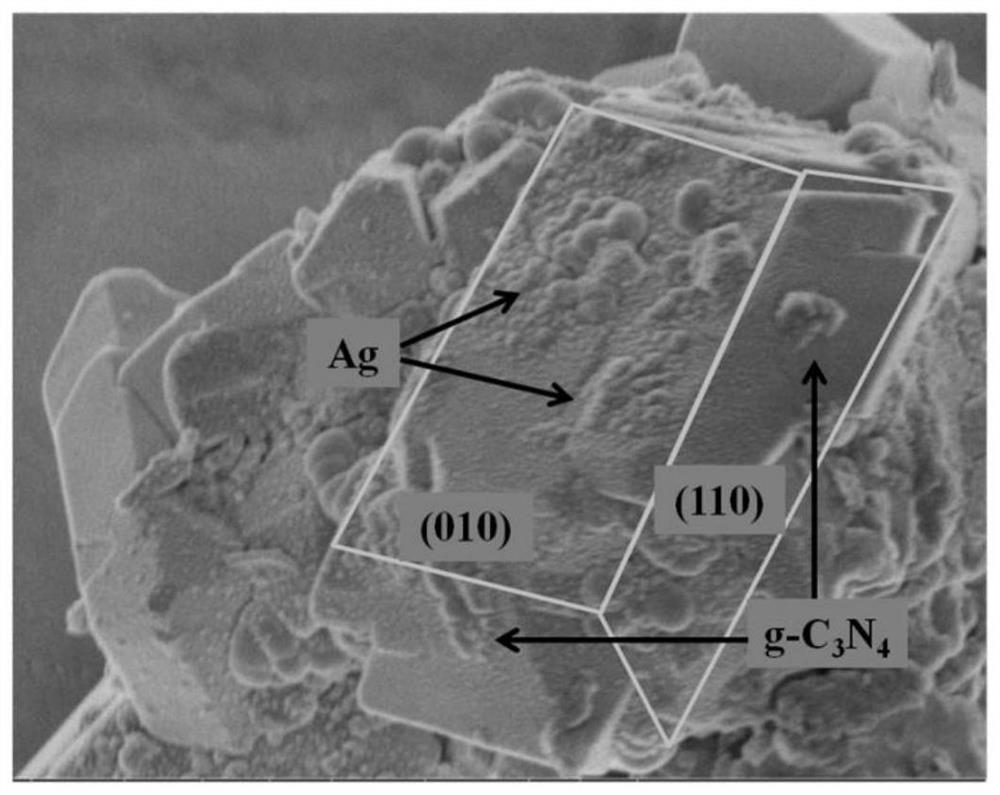

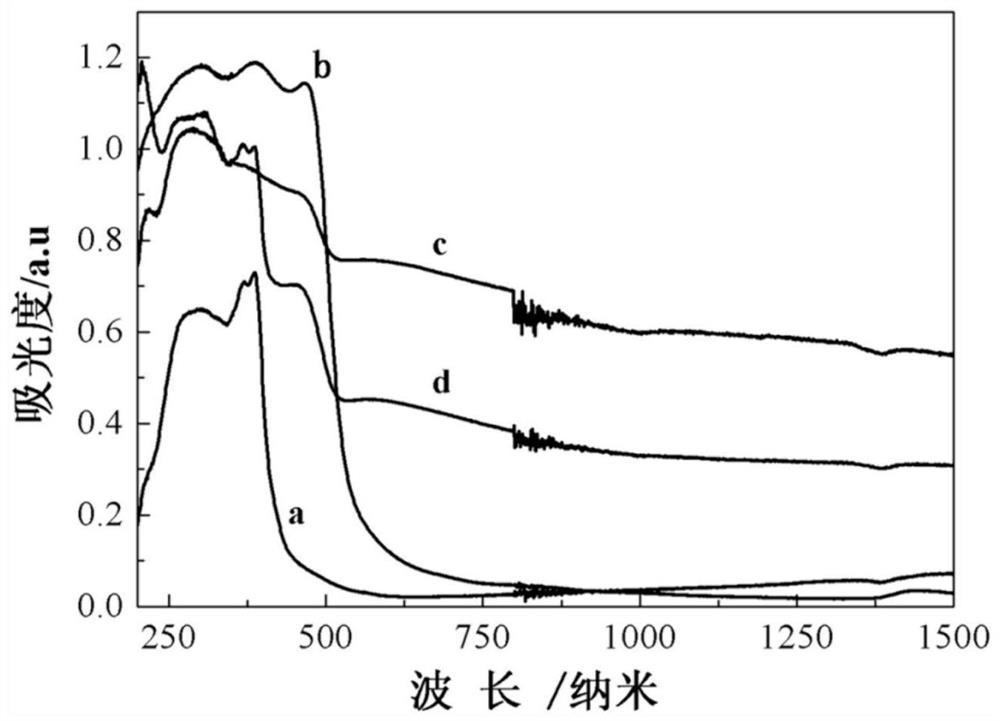

[0034] The preparation method of silver / bismuth vanadate / carbon nitride heterojunction photocatalyst of the present invention can solve BiVO by metal deposition and electrostatic adsorption method 4 The problem of poor carrier separation efficiency and high recombination rate of photogenerated electron-hole pairs involves the following steps:

[0035] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolved in 40 mL of HNO with a concentration of 1 mol / L 3 solution, after stirring evenly, directly add 6mmoL ammonium metavanadate NH 4 VO 3 , stirred for 120min to form precursor solution A;

[0036] Step 2. Precursor solution A can generally undergo a hydrothermal reaction at 70-80°C for 14-16 hours to prepare monoclinic BiVO with exposed (010) crystal plane. 4 Powder, the powder is washed with ethanol and water in turn, and then dried for later use;

[0037] Step 3, the exposed (010) crystal plane BiVO 4 Add the powder to 40mL deionized water and mix evenly, irradiate with ultraviol...

Embodiment 1

[0045] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolved in 40 mL of HNO with a concentration of 1 mol / L 3 solution, after stirring for 40min, directly add 6mmoL NH 4 VO 3 , stirred for 120min to form precursor solution A;

[0046] Step 2, Precursor solution A is hydrothermally reacted at 70°C for 16 hours to prepare BiVO with exposed (010) crystal plane 4 Powder, the powder is washed with ethanol and water in turn, and then dried for later use;

[0047] Step 3, the exposed (010) crystal plane BiVO 4 Add the powder to 40mL deionized water and mix evenly, irradiate with ultraviolet light for 0.5h, add AgNO 3 , continued ultrasonic stirring for 4h under UV light, AgNO 3 : BiVO 4 The mass ratio of Ag was 2.5:10, followed by washing with water, washing with ethanol, and drying to prepare Ag loaded on BiVO 4 (010) Ag / (010) BiVO 4 Powder.

[0048] Step 4, 10g of melamine C 3 N 3 (NH 2 ) 3 Put it into a beaker, and add 95mL1mol / L HNO prepared in advance at the same time 3 ...

Embodiment 2

[0052] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolved in 40 mL of HNO with a concentration of 1 mol / L 3 solution, after stirring for 40min, directly add 6mmoL NH 4 VO 3 , stirred for 120min to form precursor solution A;

[0053] Step 2, Precursor solution A is hydrothermally reacted at 75°C for 16 hours to prepare BiVO with exposed (010) crystal plane 4 Powder, the powder is washed with ethanol and water in turn, and then dried for later use;

[0054] Step 3, the exposed (010) crystal plane BiVO 4 Add the powder to 40mL of deionized water and mix evenly, irradiate with ultraviolet light for 1h, add AgNO 3 , continued ultrasonic stirring for 5 h under UV light, AgNO 3 : BiVO 4 The mass ratio of Ag was 2.5:10, followed by washing with water, washing with ethanol, and drying to prepare Ag loaded on BiVO 4 (010) Ag / (010) BiVO 4 Powder.

[0055] Step 4, 10g of melamine C 3 N 3 (NH 2 ) 3 Put it into a beaker, and add 95mL of 1.3mol / L HNO prepared in advance at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com