Preparation method of protective coating material for marine surrounding buildings

A protective coating, marine technology, applied in the field of preparation of protective coating materials for buildings around the ocean, to achieve the effects of strong applicability, prolonging service life and reducing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method for building protective coating materials around the ocean, comprising the following steps:

[0045] (1) prepare chitosan, sodium alginate solution;

[0046] (2) add surfactant and organic solvent respectively in chitosan, sodium alginate solution, form chitosan microemulsion and sodium alginate microemulsion respectively after mixing;

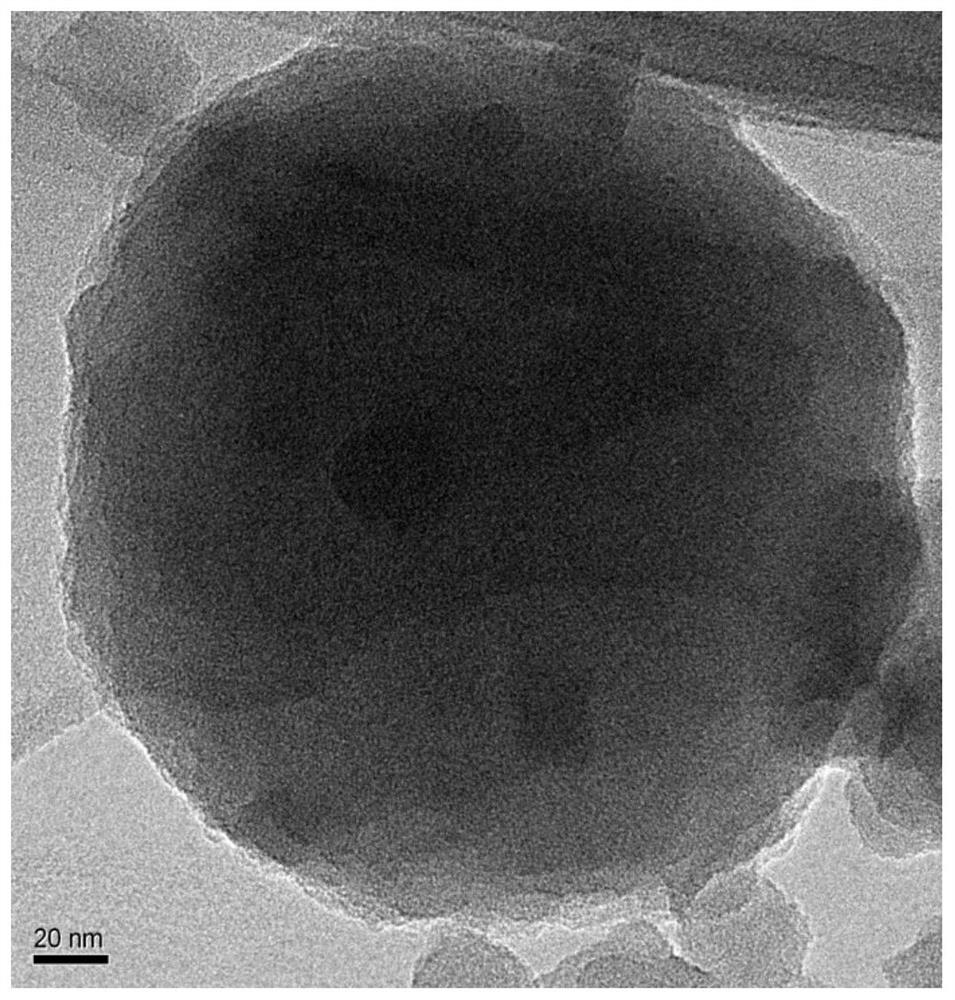

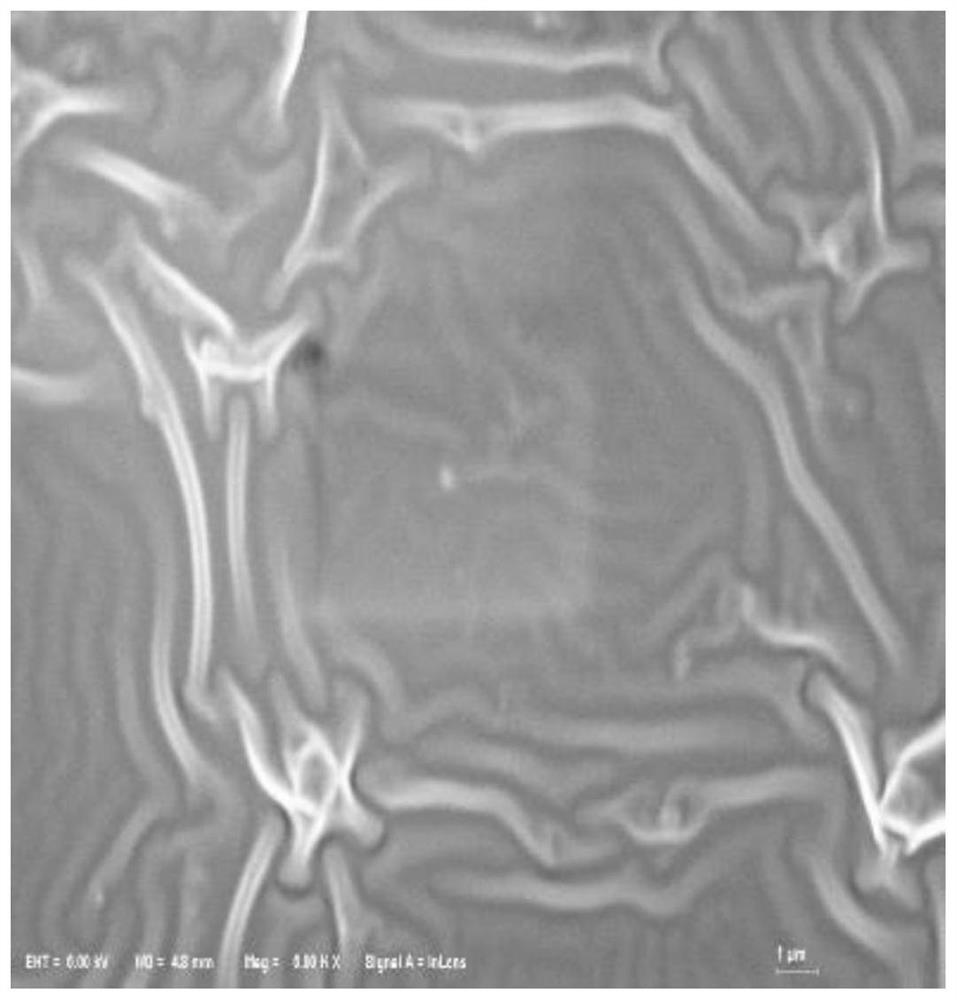

[0047] (3) sodium alginate microemulsion is added dropwise in chitosan microemulsion, after reaction is sufficient, centrifugation, washing, freeze-drying obtain chitosan-sodium alginate nano microsphere; Preferably, sodium alginate microemulsion The mass ratio of emulsion to chitosan microemulsion is 50-100:100;

[0048] (4) Add chitosan-sodium alginate nano-microspheres to the ethanol solution of monocyclohexyl maleate, then add aldehyde solution, after the reaction is complete, centrifuge, wash and dry to obtain chitosan-sodium alginate particles ;

[0049] (5) Chitosan-sodium alginate particles are added to t...

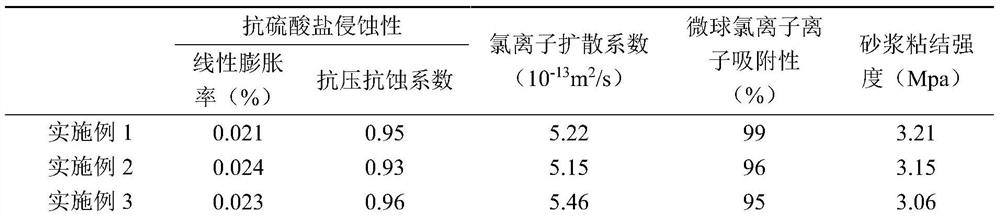

Embodiment 1

[0065] (1) Take by weighing 0.5 part of chitosan and be dissolved in 100 parts of water, and add 1.75 parts of glacial acetic acid, remove insoluble matter by centrifugation after dissolving, obtain chitosan solution;

[0066] Weigh 0.5 parts of sodium alginate and dissolve it in 100 parts of water, remove insoluble matter by centrifugation after dissolution, and adjust the pH to 5-6 with acetic acid to obtain a sodium alginate solution.

[0067] (2) Mix 100 parts of chitosan solution, 2 parts of phospholipids, and 30 parts of n-hexane, and stir at room temperature to form chitosan microemulsion. Similarly, sodium alginate microemulsion was prepared.

[0068] (3) 50 parts of sodium alginate microemulsion was gradually added dropwise to 100 parts of chitosan microemulsion, reacted for 4 hours, centrifuged, washed with deionized water, and freeze-dried to obtain chitosan-sodium alginate nanospheres.

[0069] (4) 50 parts of chitosan-sodium alginate nano-microspheres are added i...

Embodiment 2

[0075] (1) Take by weighing 0.6 part of chitosan and be dissolved in 100 parts of water, and add 1.75 parts by weight of glacial acetic acid, remove insolubles by centrifugation after dissolving, obtain chitosan solution;

[0076] Weigh 0.6 parts of sodium alginate and dissolve it in 100 parts of water, remove insoluble matter by centrifugation after dissolution, and adjust the pH to 5-6 with acetic acid to obtain a sodium alginate solution.

[0077] (2) Mix 100 parts of chitosan solution, 3 parts of choline, and 35 parts of cyclohexane, and stir at room temperature to form a chitosan microemulsion. Similarly, sodium alginate microemulsion was prepared.

[0078] (3) 60 parts of sodium alginate microemulsion was gradually added dropwise to 100 parts of chitosan microemulsion, reacted for 4 hours, centrifuged, washed with deionized water, and freeze-dried to obtain chitosan-sodium alginate nanospheres.

[0079] (4) 60 parts of chitosan-sodium alginate nanomicrospheres are added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com