Polyphenyl ether/high impact polystyrene composition with low linear expansion coefficient and preparation method thereof

A low linear expansion, polystyrene technology, applied in the field of materials, can solve the problems of difficulty in meeting the requirements of assembly of parts, large linear expansion coefficient, difficult molding and processing, etc., and achieves increased spiral flow, high dielectric strength, and reduced linearity. Effect of Expansion Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

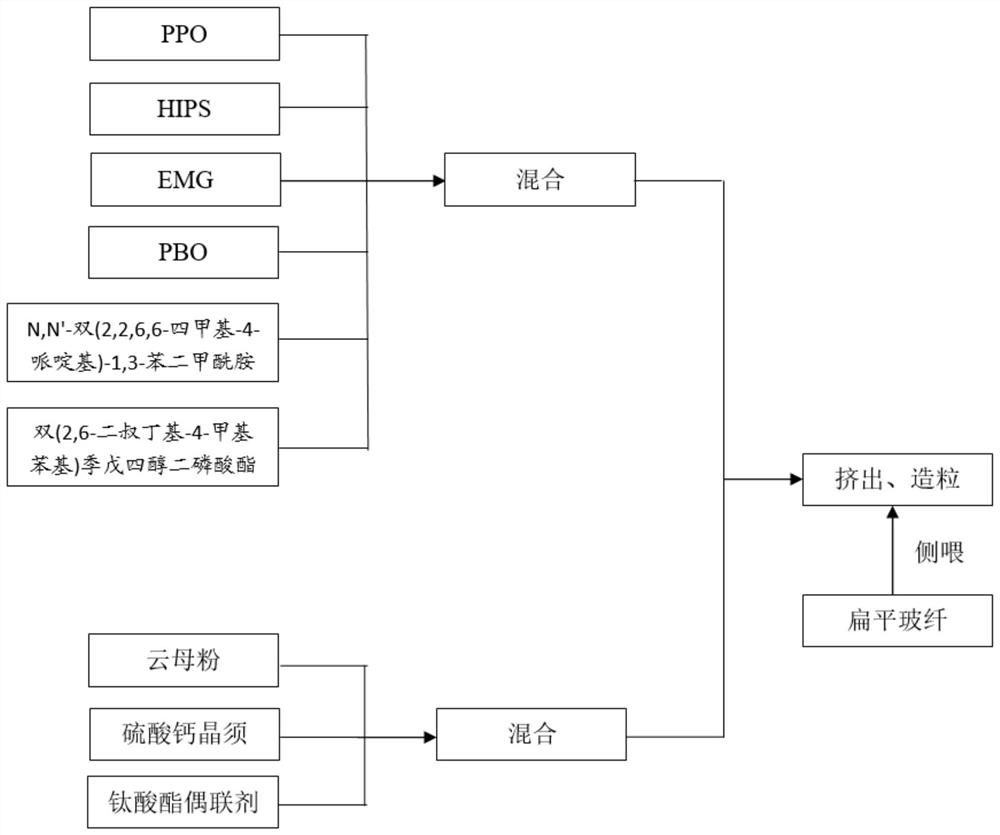

Method used

Image

Examples

Embodiment 1

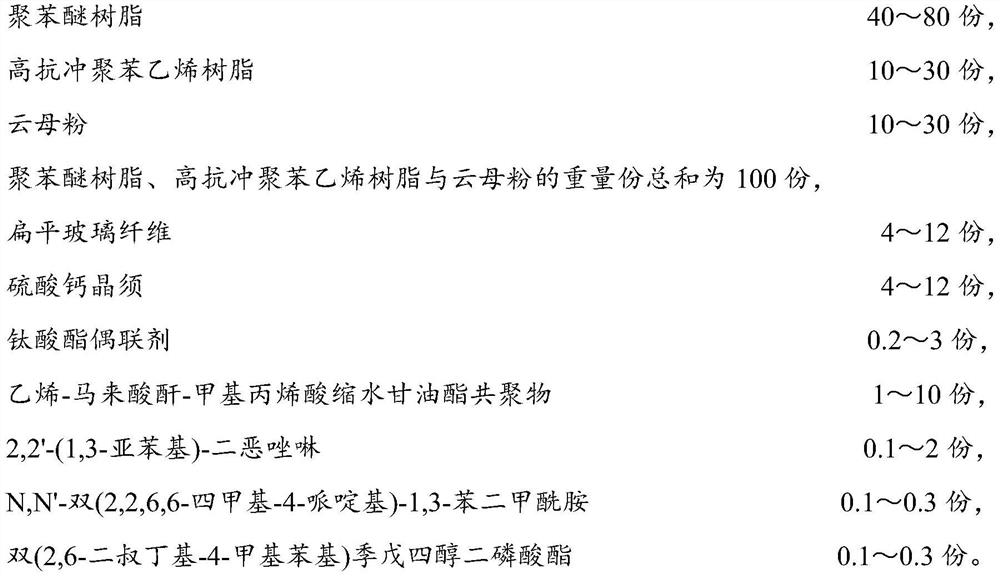

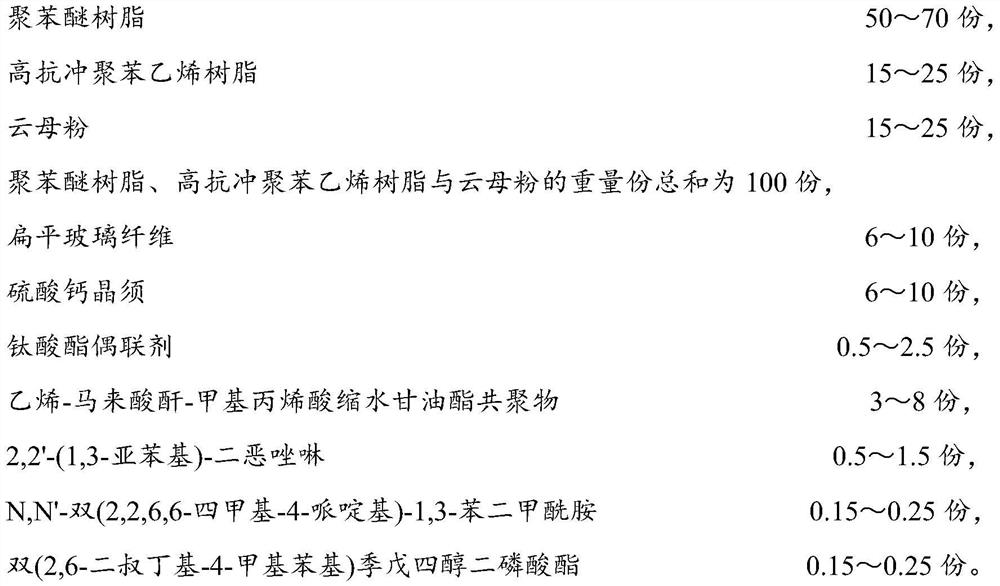

[0088] This embodiment provides a low linear expansion coefficient polyphenylene ether / high impact polystyrene composition, which is prepared from the following raw materials in parts by weight:

[0089] 80 parts of polyphenylene ether resin,

[0090] High impact polystyrene resin 10 parts,

[0092] The sum of the parts by weight of polyphenylene ether resin, high-impact polystyrene resin and mica powder is 100 parts,

[0093]

[0094] The preparation method of the above-mentioned low linear expansion coefficient polyphenylene ether / high-impact polystyrene composition comprises the following steps:

[0095] (1) Dry the polyphenylene ether resin and high-impact polystyrene resin at a temperature of 110° C. for 4 hours, then cool, and place the cooled polyphenylene ether resin, high-impact polystyrene resin and the Ethylene-maleic anhydride-glycidyl methacrylate copolymer, 2,2'-(1,3-phenylene)-bisoxazoline, N,N'-bis(2,2,6,6 -Tetramethyl-4-pi...

Embodiment 2

[0100] This embodiment provides a low linear expansion coefficient polyphenylene ether / high impact polystyrene composition, which is prepared from the following raw materials in parts by weight:

[0101] 40 parts of polyphenylene ether resin,

[0102] High impact polystyrene resin 30 parts,

[0103] 30 parts of mica powder,

[0104] The sum of the parts by weight of polyphenylene ether resin, high-impact polystyrene resin and mica powder is 100 parts,

[0105]

[0106] The preparation method of the above-mentioned low linear expansion coefficient polyphenylene ether / high-impact polystyrene composition comprises the following steps:

[0107] (1) After drying the polyphenylene ether resin and high-impact polystyrene resin at a temperature of 80° C. for 8 hours, cooling, the cooled polyphenylene ether resin, high-impact polystyrene resin and the Ethylene-maleic anhydride-glycidyl methacrylate copolymer, 2,2'-(1,3-phenylene)-bisoxazoline, N,N'-bis(2,2,6,6 -Tetramethyl-4-pip...

Embodiment 3

[0112] This embodiment provides a low linear expansion coefficient polyphenylene ether / high impact polystyrene composition, which is prepared from the following raw materials in parts by weight:

[0113] 70 parts of polyphenylene ether resin,

[0114] High impact polystyrene resin 15 parts,

[0115] 15 parts mica powder,

[0116] The sum of the parts by weight of polyphenylene ether resin, high-impact polystyrene resin and mica powder is 100 parts,

[0117]

[0118] The preparation method of the above-mentioned low linear expansion coefficient polyphenylene ether / high-impact polystyrene composition comprises the following steps:

[0119] (1) After drying the polyphenylene ether resin and the high-impact polystyrene resin at a temperature of 100°C for 4 hours, cooling, the cooled polyphenylene ether resin, high-impact polystyrene resin and the Ethylene-maleic anhydride-glycidyl methacrylate copolymer, 2,2'-(1,3-phenylene)-bisoxazoline, N,N'-bis(2,2,6,6 -Tetramethyl-4-pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com