Production process of color-changing pearlescent pigment

A pearlescent pigment and production process technology, applied in the direction of pigment preparation, inorganic pigment processing, fibrous filler, etc., can solve the problems of difficulty in reaching iron blue, limited to the vicinity of gold, and different total surface area of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The present embodiment provides a kind of production technology of color-changing pearlescent pigment, and the steps are as follows:

[0074] (1) Add 40 grams of glass flakes, with a particle size of 10 to 40 microns, into 800 ml of deionized water to form a suspension, and stir and heat to 75°C.

[0075] (2) then adjust the pH value of the suspension to 1.0-1.5 with 18wt% hydrochloric acid, and then meter the 80g / L tin chloride solution at a speed of 20-30mL / h under stirring, the amount of which is finally obtained The mass of tin oxide is based on 0.3% of the mica mass. During this process, the pH value is kept stable by adding 15wt% sodium hydroxide solution dropwise. After the addition is completed, stir at constant temperature for 30 minutes.

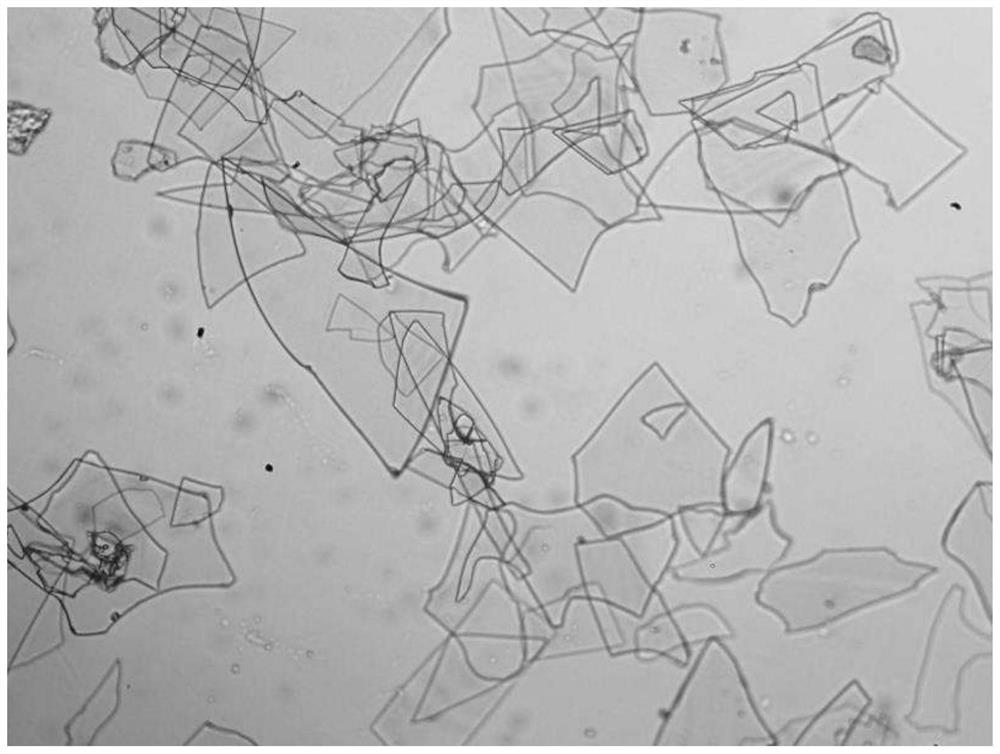

[0076] (3) then use 15wt% sodium hydroxide solution to adjust the pH value of the suspension to 2.0-2.2, and now the color of the suspension is figure 1 silvery white, under the microscope figure 2All the colors shown are...

Embodiment 2

[0083] The present embodiment provides a kind of production technology of color-changing pearlescent pigment, and the steps are as follows:

[0084] (1) Add 60 grams of muscovite powder, with a particle size of 10 to 60 microns, into 1000 ml of deionized water to form a suspension, and stir and heat to 75°C.

[0085] (2) Then use 18wt% hydrochloric acid to adjust the pH value of the suspension to 1.0-1.5, then meter and add 100g / L tin chloride solution at a speed of 20-30mL / h under stirring, and the addition amount is the titanium dioxide obtained finally The mass is 0.5% of the mica mass. During this process, the pH value is kept stable by adding 15 wt% sodium hydroxide solution dropwise. After the addition is completed, stir at constant temperature for 30 minutes.

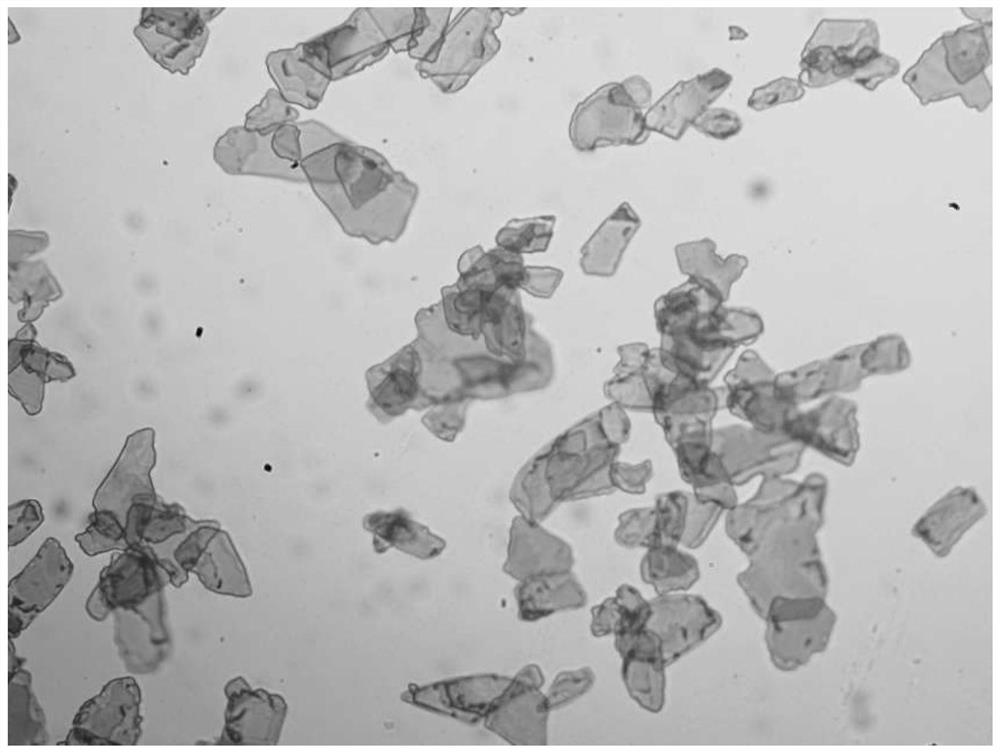

[0086] (3) then use 15wt% sodium hydroxide solution to adjust the pH value of the suspension to 3.1-3.2, and now the color of the suspension is Figure 10 silvery white, under the microscope Figure 11 The seve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com