Preparation method of antibacterial, antiviral and flame-retardant fabric

A flame-retardant fabric, anti-virus technology, applied in the direction of flame-retardant fiber, spray/jet textile material treatment, textile, etc., can solve the problems such as the antibacterial and antiviral effects of cotton knitted fabrics that have not been mentioned, and achieve excellent antibacterial and antiviral properties. Virus and flame retardant properties, low cost, easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

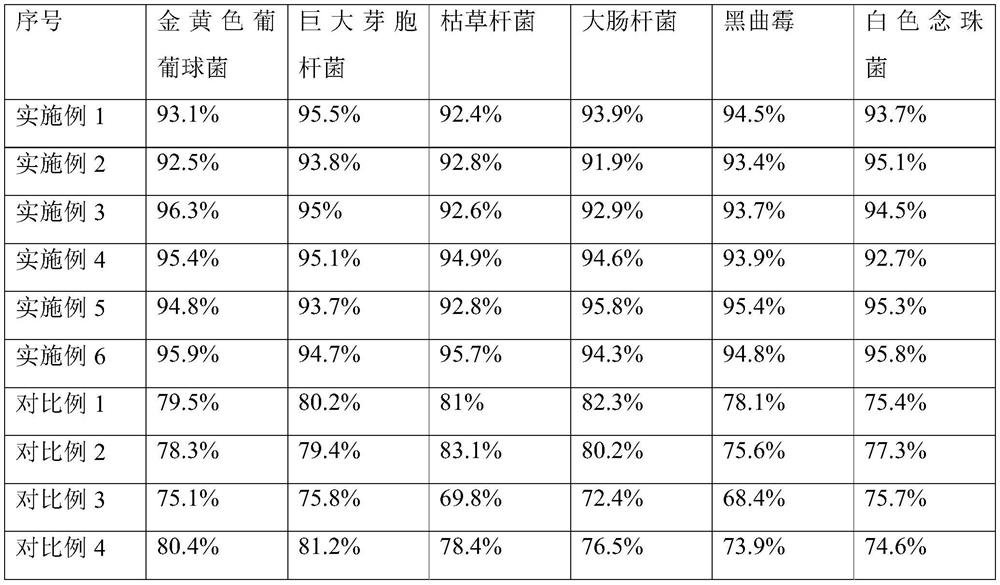

Examples

Embodiment 1

[0030] (1) Pre-treatment: according to the ratio of nano-titanium dioxide, sodium stearate, trisodium phosphate, and water in a ratio of 10:30:1:100 by mass, first disperse nano-titanium dioxide at 30°C for 10 minutes until dissolved After being stirred uniformly in the aqueous solution of trisodium phosphate, sodium stearate is added and mixed uniformly to obtain the antibacterial and antiviral modifier.

[0031] Spray the antibacterial and antiviral modifiers prepared above on the dyed PET fibers and cotton fibers respectively at 30°C, and dry them;

[0032] (2) Weaving: After the dried PET fiber and cotton fiber are mixed evenly, PET / cotton blended yarn is made, and then PET / cotton blended fabric is formed through weaving; the mass ratio of PET and cotton is 35 / 65;

[0033] (3) post-treatment: according to the ratio of nano-titanium dioxide, nano-magnesium hydroxide, sodium stearate, trisodium phosphate, and water, the ratio of mass and number of parts is 10:20:30:5:110, fi...

Embodiment 2

[0036] (1) Pretreatment: According to the ratio of nano-titanium dioxide, sodium stearate, trisodium phosphate, and water in the ratio of mass and number of 20:40:2:100, first disperse nano-titanium dioxide at 30°C for 8 minutes until dissolved After being stirred uniformly in the aqueous solution of trisodium phosphate, sodium stearate is added and mixed uniformly to obtain the antibacterial and antiviral modifier.

[0037] Spray the antibacterial and antiviral modifiers prepared above on the dyed PET fibers and cotton fibers respectively at 25°C, and dry them;

[0038] (2) Weaving: After the dried PET fiber and cotton fiber are mixed evenly, PET / cotton blended yarn is made, and then PET / cotton blended fabric is formed through weaving; the mass ratio of PET and cotton is 35 / 65;

[0039] (3) post-treatment: according to the ratio of nano-titanium dioxide, nano-magnesium hydroxide, sodium stearate, trisodium phosphate, and water, the ratio of mass and number of parts is 20:10:4...

Embodiment 3

[0042](1) Pre-treatment: according to the ratio of nano-titanium dioxide, sodium stearate, trisodium phosphate, and water in a mass-number ratio of 15:35:2:100, first disperse nano-titanium dioxide at 30°C for 7 minutes until dissolved After being stirred uniformly in the aqueous solution of trisodium phosphate, sodium stearate is added and mixed uniformly to obtain the antibacterial and antiviral modifier.

[0043] Spray the antibacterial and antiviral modifiers prepared above on the dyed PET fibers and cotton fibers respectively at 20°C, and dry them;

[0044] (2) Weaving: After the dried PET fiber and cotton fiber are evenly mixed, PET / cotton blended yarn is made, and then PET / cotton blended fabric is formed through weaving; the mass ratio of PET and cotton is 30 / 70;

[0045] (3) post-treatment: according to the ratio of nano-titanium dioxide, nano-magnesium hydroxide, sodium stearate, trisodium phosphate, and water, the ratio of mass and number of parts is 15:15:40:6:120, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com