High-magnification lead storage battery for communication

A lead-acid battery, high-rate technology, applied in lead-acid batteries, lead-acid battery electrodes, battery electrodes, etc., can solve problems such as battery failure, dendrite short-circuit, etc., to reduce self-discharge, delay softening and shedding, and improve high-rate discharge. The effect of the voltage platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

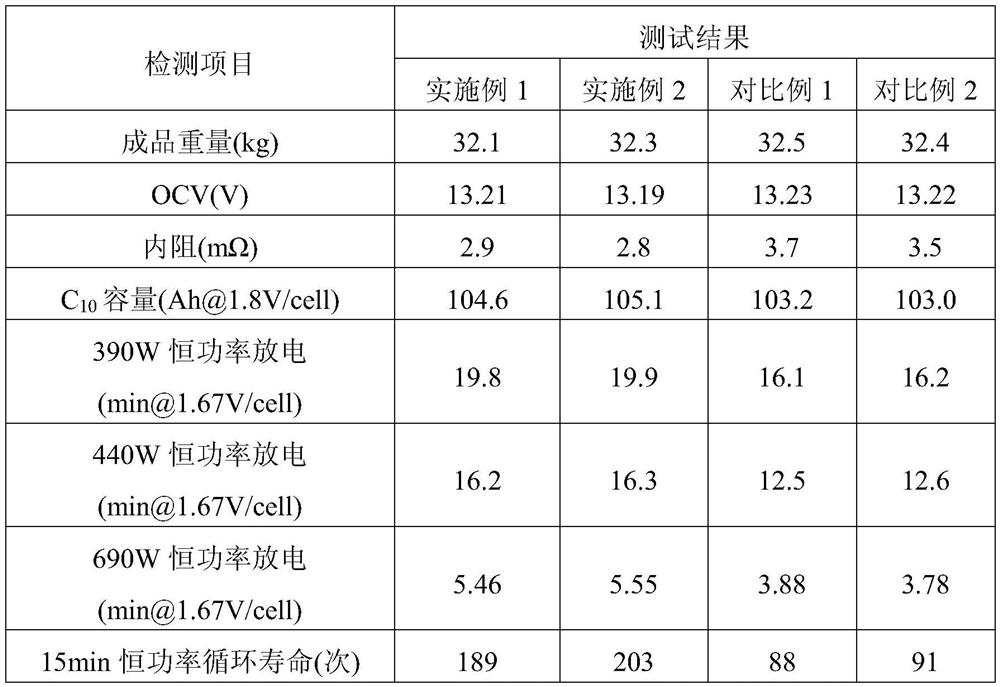

Embodiment 1

[0027] Positive plate lead paste formula: lead powder 1000kg, red lead 50kg, silver-plated carbon fiber 0.5kg, expanded graphite 2kg, sodium bicarbonate 8kg, magnesium silicate 2kg, bismuth oxide 0.5kg, Teflon solution 2kg, density 1.40g / ml 110kg of sulfuric acid, 110kg of deionized water, apparent density of lead paste 4.2g / cm 3 ;

[0028] Negative plate lead paste formula: lead powder 1000kg, silver-plated carbon fiber 1kg, acetylene carbon black 3kg, ultra-fine barium sulfate 12kg, lignin 4kg, humic acid 1kg, carbon nanotube slurry 2.5kg, polyester fiber 0.5kg, density 1.40g / ml sulfuric acid 90kg, deionized water 110kg, lead paste apparent density 4.3g / cm 3 ;

[0029] Electrolyte solution formula: 1.24g / ml sulfuric acid, adding anhydrous sodium sulfate at a ratio of 12g / L to make a sulfuric acid solution; dissolving stannous sulfate in deionized water at a ratio of 10% by weight to make a stannous sulfate aqueous solution; stannous sulfate The aqueous solution is mixed w...

Embodiment 2

[0031] Positive plate lead paste formula: lead powder 1000kg, red lead 30kg, silver-plated carbon fiber 1kg, expanded graphite 3kg, sodium bicarbonate 10kg, magnesium silicate 1.5kg, bismuth oxide 0.3kg, Teflon solution 1.5kg, density 1.40g / ml sulfuric acid 120kg, deionized water 100kg, lead paste apparent density 4.2g / cm 3 ;

[0032] Negative plate lead paste formula: lead powder 1000kg, silver-plated carbon fiber 1.5kg, acetylene carbon black 2.5kg, ultrafine barium sulfate 15kg, lignin 2.5kg, humic acid 2kg, carbon nanotube slurry 5kg, polyester fiber 1kg, 110kg of sulfuric acid with a density of 1.40g / ml, 100kg of deionized water, and the apparent density of the lead paste is 4.3g / cm 3 ;

[0033] Electrolyte solution formula: 1.28g / ml sulfuric acid, adding anhydrous sodium sulfate at a ratio of 16g / L to make a sulfuric acid solution; dissolving stannous sulfate in deionized water at a ratio of 5% by weight to make a stannous sulfate aqueous solution; stannous sulfate T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com