A kind of negative electrode of lead-carbon battery

A lead-carbon battery and negative electrode technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of uneven size, decreased hydrogen suppression effect, poor consistency, etc., and achieve increased utilization, increased hydrogen evolution resistance, high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

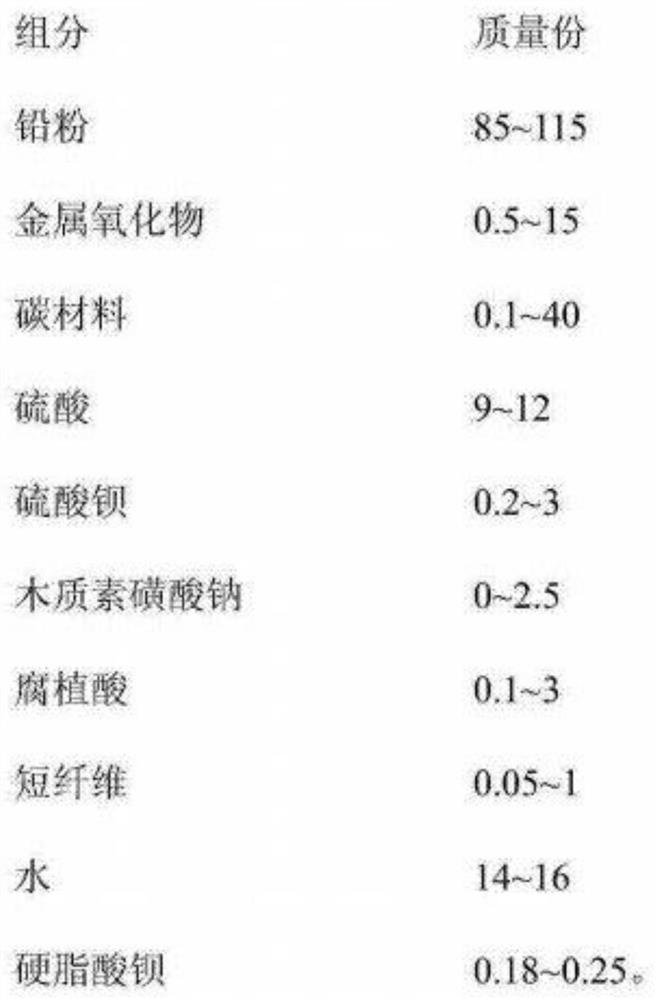

[0043] A lead-carbon battery negative pole, the negative pole comprises the following components in parts by mass:

[0044]

[0045]

[0046] The heteroatom-doped carbon material is a mixture of carbon black and carbon nanotubes, the mass ratio of carbon black and carbon nanotubes is 3:1, and the mass fraction of heteroatom P in the composite of carbon black and carbon nanotubes is 2.25%. , the metal oxide is indium oxide, and the metal oxide is coated on the surface of the mixture of carbon black and carbon nanotubes. The specific surface area of activated carbon is 1250m 2 / g.

Embodiment 2

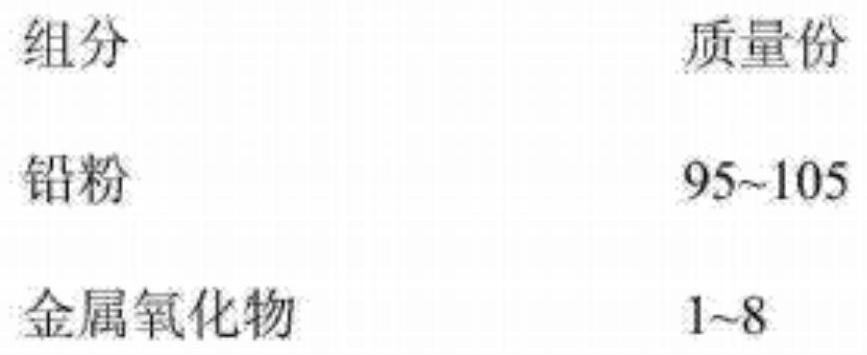

[0048] A lead-carbon battery negative pole, the negative pole comprises the following components in parts by mass:

[0049]

[0050] 0.25 parts of barium stearate.

[0051] The heteroatom-doped carbon material is a mixture of expanded graphite and carbon nanofibers, the mass ratio of expanded graphite to carbon nanofibers is 2:1, and the mass percentage of heteroatom N in the composite of expanded graphite and carbon nanofibers is 4.68 %, the metal oxide is a mixture of zinc oxide and bismuth oxide, the mass ratio of zinc oxide and bismuth oxide is 1:1, the metal oxide is coated on the surface of the mixture of expanded graphite and carbon nanofibers, and the specific surface area of activated carbon is 1600m 2 / g.

Embodiment 3

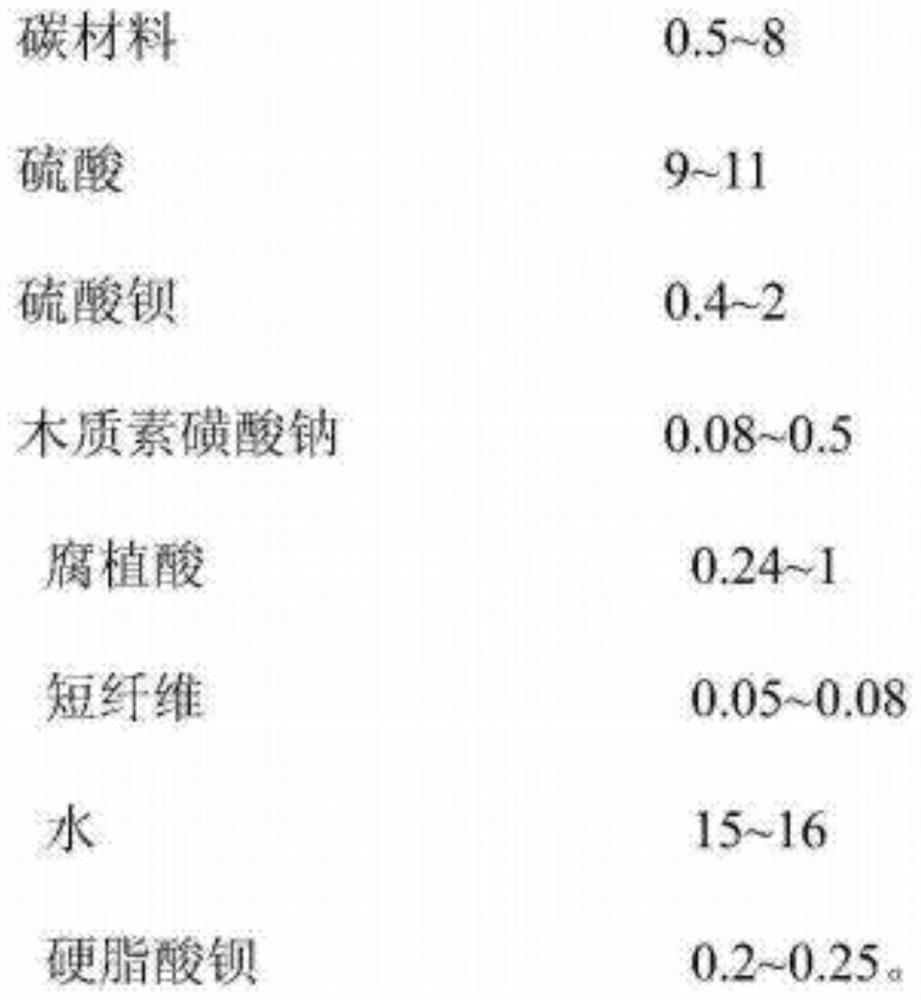

[0053] A lead-carbon battery negative pole, the negative pole comprises the following components in parts by mass:

[0054]

[0055] The heteroatom-doped carbon material is a mixture of acetylene black and carbon nanobelts, the mass ratio of acetylene black and carbon nanobelts is 1:1, and the mass fraction of heteroatoms N and B in the doped composite of acetylene black and carbon nanobelts The metal oxide is a mixture of gallium oxide and germanium oxide, the mass ratio of gallium oxide and germanium oxide is 1:2, the metal oxide is coated on the surface of the mixture of acetylene black and carbon nanobelts, and the specific surface area of the activated carbon is 1460m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com