Preparation method of flexible battery pack and prepared flexible battery pack

A flexible battery pack and battery pack technology, which is applied in the manufacture of alkaline batteries, small flat batteries/batteries, alkaline batteries, etc., can solve the problems of battery performance attenuation, low effective efficiency, and increased battery internal resistance, and prevent Effect of contact short circuit, reduction of manufacturing cost, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

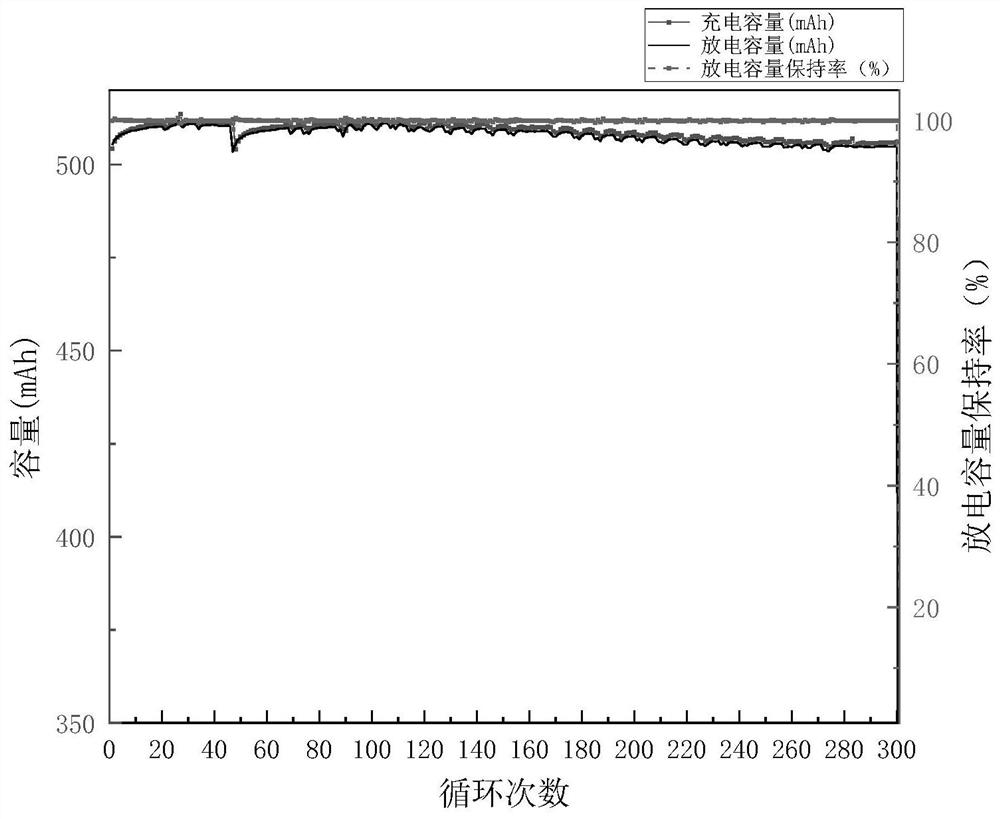

Embodiment 1

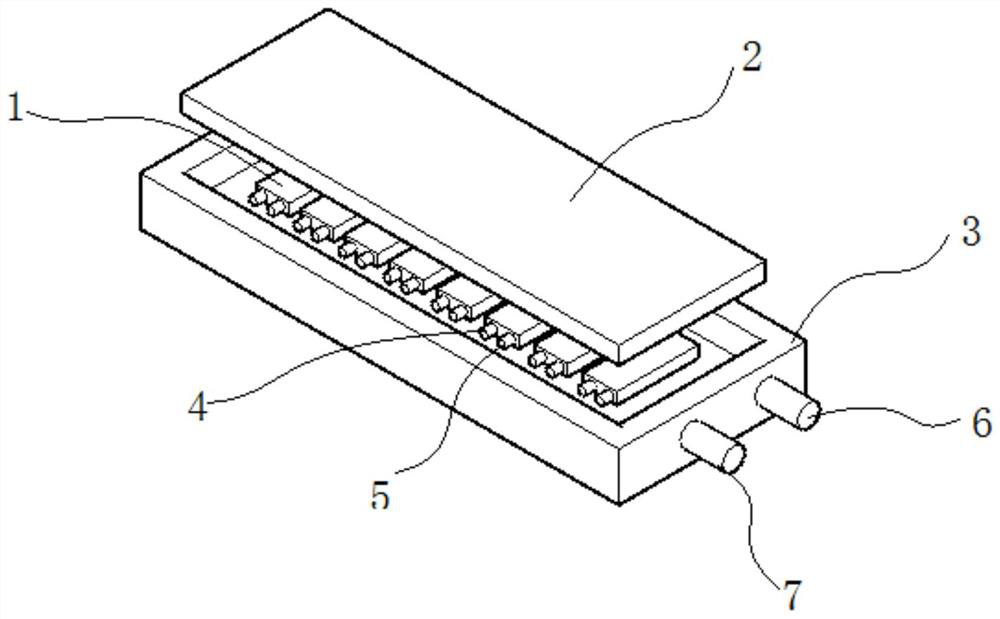

[0061] Preparation method of flexible battery pack

[0062] (1) Preparation of single cell 1: in an argon-protected glove box, lithium cobaltate was used as the positive electrode active material, and the positive electrode sheet was coated on aluminum foil by a coating machine, and artificial graphite was used as the negative electrode active material. Use a coating machine to coat the copper foil to make the negative electrode sheet, and prepare the core by winding the positive electrode sheet, diaphragm and negative electrode sheet. When winding and forming, the positive electrode sheet, separator and negative electrode sheet are stacked in sequence and then wound. , the positive electrode is in the inner layer, the diaphragm is located between the positive and negative electrodes, the negative electrode is in the outer layer, and then the core is packaged for the first time with aluminum-plastic film;

[0063] Inject a lithium salt of 1mol / L lithium hexafluorophosphate (Li...

Embodiment 2

[0071] Preparation method of flexible battery pack

[0072] (1) Preparation of single cell 1: This step is the same as in Example 1;

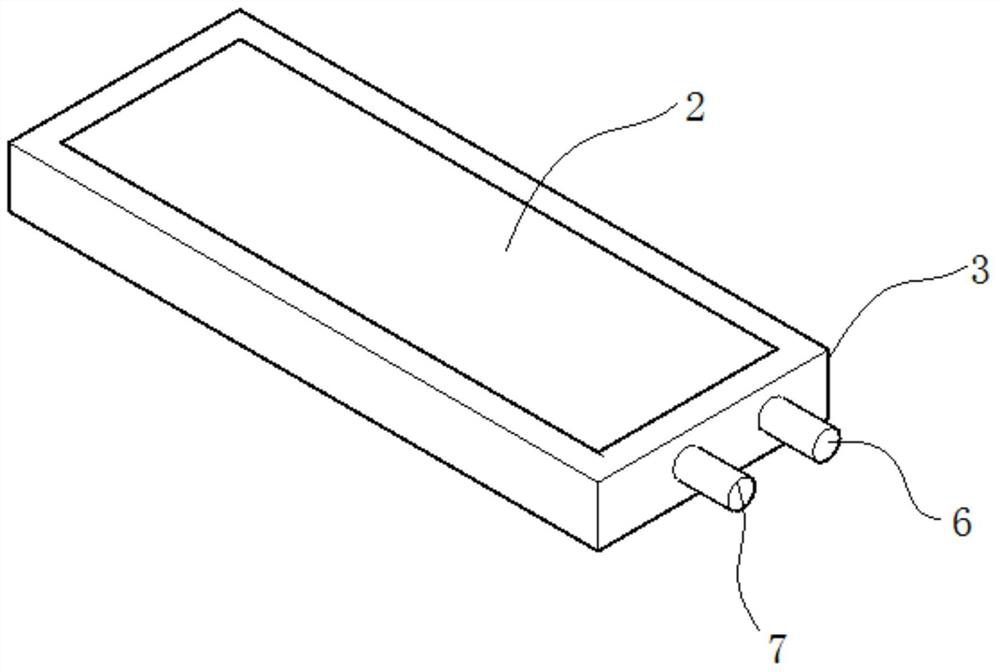

[0073] (2) Preparation of a battery pack: the eight single cells 1 prepared in step (1) are connected in parallel to form a battery pack, and the positive pole tab and the negative pole tab of the battery are installed on the ends of the single cell 1 respectively, and the Wires (not shown in the figure) connect 8 single cells 1 in parallel, the distance between adjacent single cells 1 is 0mm, and the positive pole lugs 2 of adjacent single cells 1 are connected by wires. Negative pole tabs 3 of adjacent single cells 1 are connected by wires; in this embodiment, the positive pole tab 2 and the negative pole tab 3 are prior art;

[0074] (3) Preparation of mold: Weigh 100g of black silica gel, vulcanize and mold at 180 degrees, and prepare flexible carrier 3 and flexible cover plate 2. The preparation method of the precursor material in this em...

Embodiment 3

[0080] Preparation method of flexible battery pack

[0081] (1) Preparation of single cell 1: This step is the same as in Example 1;

[0082] (2) Preparation of a battery pack: the eight single cells 1 prepared in step (1) are connected in series to form a battery pack, and the positive pole tab and the negative pole tab of the battery are installed on the ends of the single cell 1 respectively. Wires (not shown in the figure) connect 8 single cells 1 in series, the distance between adjacent single cells 1 is 1mm, and the distance between the positive tab 2 and the negative tab 3 of adjacent single cells 1 Connected by wires (not shown); in the present embodiment, the positive pole tab 2 and the negative pole tab 3 are prior art;

[0083] (3) Prepare the mold: Weigh 20g of soft polyvinyl chloride (PVC) and 0.1g of black colorant to prepare the precursor material, pour the precursor material into the mold to prepare a flexible carrier 3 and a flexible cover 2, this The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com