Bimetal alloy-halloysite composite catalyst and preparation method and application thereof

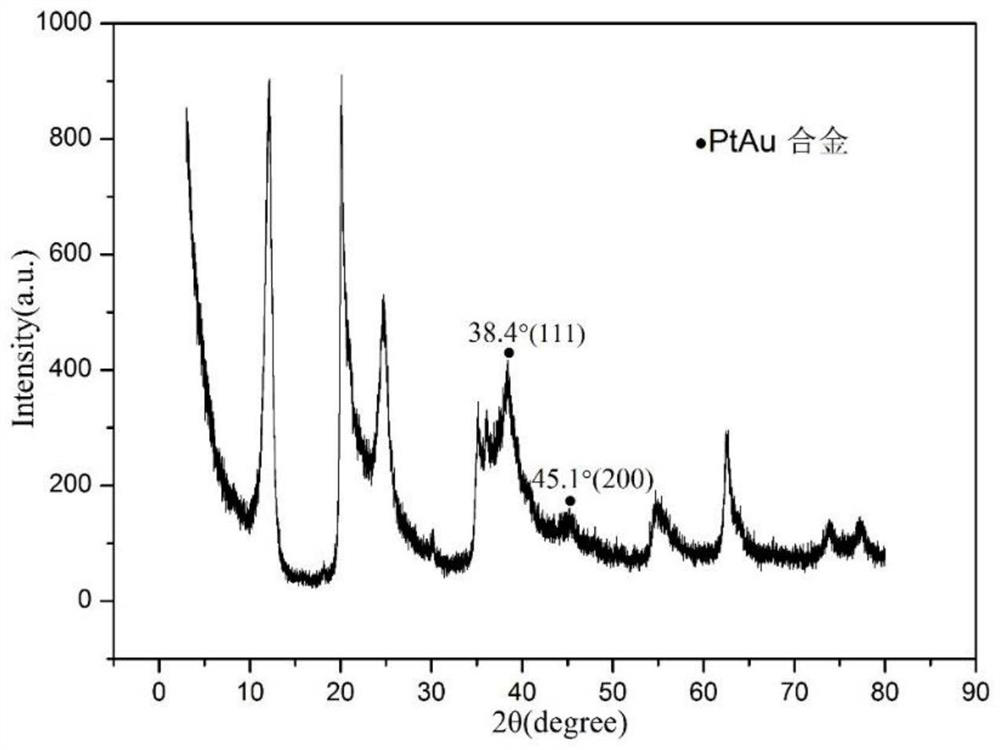

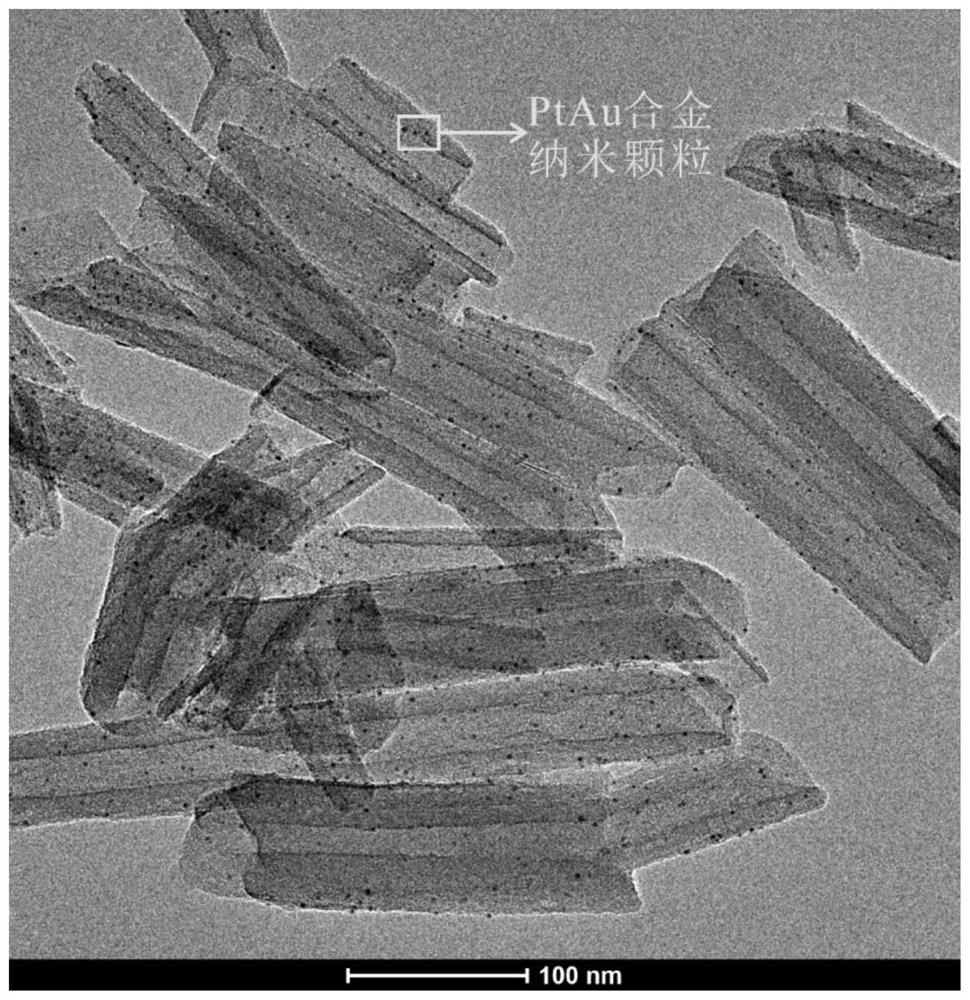

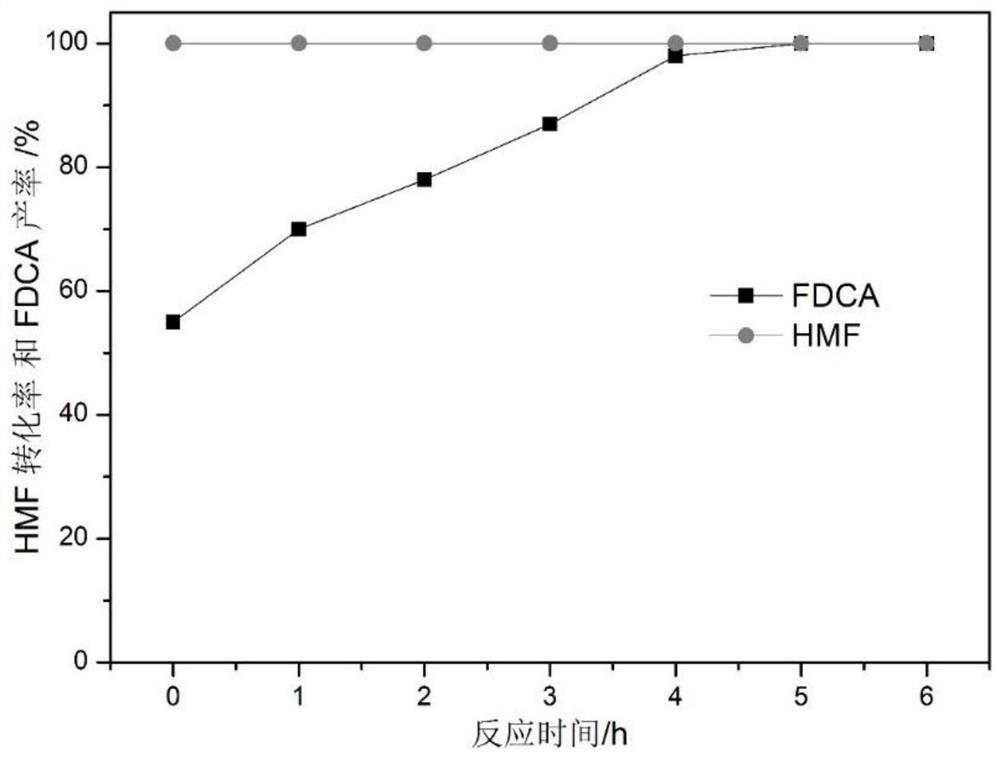

A composite catalyst and bimetallic technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem of unfavorable exposure of metal surface catalytic active centers and catalyst preparation process Complexity and other issues, to achieve the effect of easy recycling and reuse, simple preparation method and application process, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix 40mL of 3-aminopropyltrimethoxysilane and 360mL of ethanol uniformly to obtain a mixed solution, then add 40g of halloysite to the above mixed solution, and 100W ultrasonic 2h to obtain a uniform suspension of halloysite;

[0031] (2) Stir and reflux the halloysite suspension obtained in step (1) for 24h at 80°C, then centrifuge at 4000rpm for 10min to separate, keep the solid, then dry at 50°C for 12h, manually grind and pass through a 100-mesh sieve Net, get modified halloysite;

[0032] (3) Add 20g of the modified halloysite obtained in step (2) to 2000mL of water, 100W ultrasonic 2h to make it uniformly dispersed, then add 242mL of sodium chloroplatinate aqueous solution with a concentration of 10mg / mL and 43mL of 10mg / mL Aqueous sodium chloroaurate solution, and stirred at room temperature for 24h, obtained the suspension of double metal ion-halloysite complex;

[0033] (4) Finally, add 10 g of gallic acid to the suspension of the double metal ion-halloysi...

Embodiment 2

[0037] (1) Mix 100mL of 3-aminopropyltriethoxysilane and 500mL of ethanol uniformly to obtain a mixed solution, then add 12g of halloysite to the above mixed solution, and 100W ultrasonic for 0.5h to obtain a uniform suspension of halloysite;

[0038] (2) Stir and reflux the halloysite suspension obtained in step (1) for 18 hours at 100°C, then centrifuge at 4000rpm for 10 minutes to separate, retain the solid, then dry at 150°C for 4 hours, manually grind and pass through a 100-mesh sieve Net, get modified halloysite;

[0039] (3) Add 10g of the modified halloysite obtained in step (2) to 500mL of water, 100W ultrasonic 0.5h to make it uniformly dispersed, then add 26mL of chloroplatinic acid aqueous solution with a concentration of 5mg / mL and 26mL with a concentration of 5mg / mL Chlorauric acid aqueous solution, and stirred at room temperature 12h, obtains the suspension of double metal ion-halloysite complex;

[0040] (4) Finally, 6 g of sodium borohydride was added to the ...

Embodiment 3

[0044] (1) Mix 10mL of 3-aminopropyltriethoxysilane and 1000mL of toluene uniformly to obtain a mixed solution, then add 25g of halloysite to the above mixed solution, and 100W ultrasonic for 2h to obtain a uniform suspension of halloysite;

[0045] (2) Stir and reflux the halloysite suspension obtained in step (1) for 12 hours at 120°C, then centrifuge at 4000rpm for 10 minutes to separate, retain the solid, then dry at 100°C for 10 hours, manually grind and pass through a 100-mesh sieve Net, get modified halloysite;

[0046] (3) Add 15g of the modified halloysite obtained in step (2) to 3000mL of water, 100W ultrasonic 2h to make it evenly dispersed, then add 38mL of potassium chloroplatinate aqueous solution with a concentration of 1mg / mL and 116mL with a concentration of 1mg / mL Potassium chloroaurate aqueous solution, and stirred at room temperature 18h, obtains the suspension of double metal ion-halloysite complex;

[0047] (4) Finally, 7g of ascorbic acid was added to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com