N-doped porous carbon-coated MoP nanorod material, and preparation method and application thereof

A technology of nanorods and porous carbon, which is applied in the preparation/purification of carbon, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of reduced catalytic hydrogen evolution reaction activity and reduced material active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

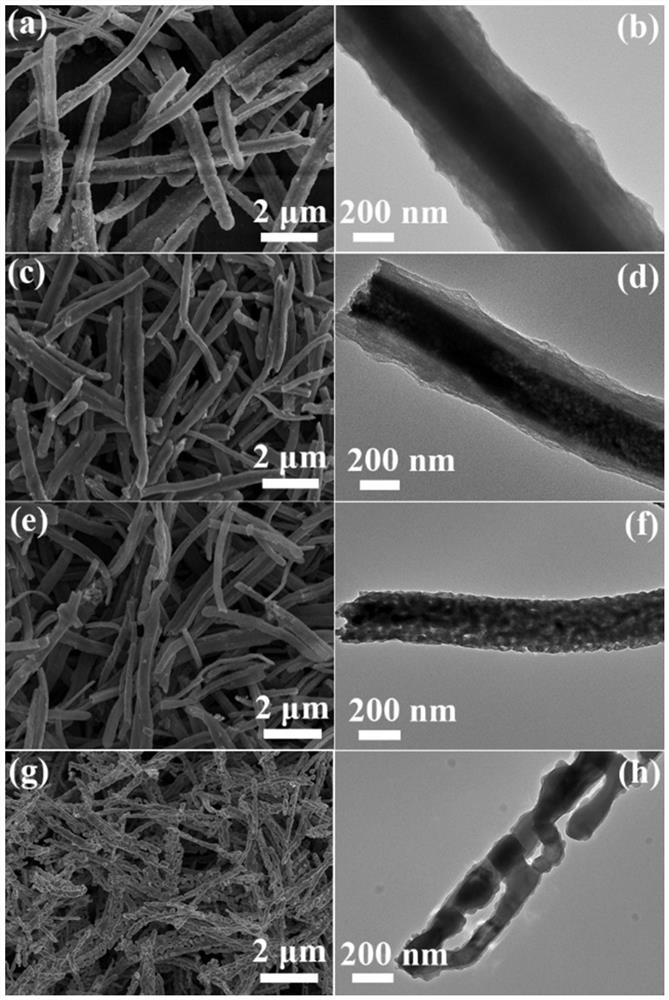

[0022] The invention provides a method for preparing an N-doped porous carbon-coated MoP nanorod material, comprising:

[0023] 1) MoO 3 Nanorods, surfactants, zinc sources, and dimethylimidazole are contacted in a solvent to prepare precursor powders;

[0024] 2) The precursor powder is calcined and carbonized under a protective gas, and then the calcined carbonized product is subjected to phosphating treatment to obtain a MoP nanorod material coated with N-doped porous carbon.

[0025] In step 1), the amount of each material can be selected in a wide range, but in order to improve the catalytic activity of the prepared MoP nanorod material, preferably, in step 1), MoO 3 The dosage ratio of nanorods, surfactant, zinc source and dimethylimidazole is 0.1g: 0.2-0.5g: 1-4mmol: 10-30mmol.

[0026] In step 1), the amount of solvent can be selected in a wide range, but in order to improve the catalytic activity of the prepared MoP nanorod material, preferably, in step 1), MoO 3 T...

preparation example 1

[0049] MoO 3 Preparation of nanorods:

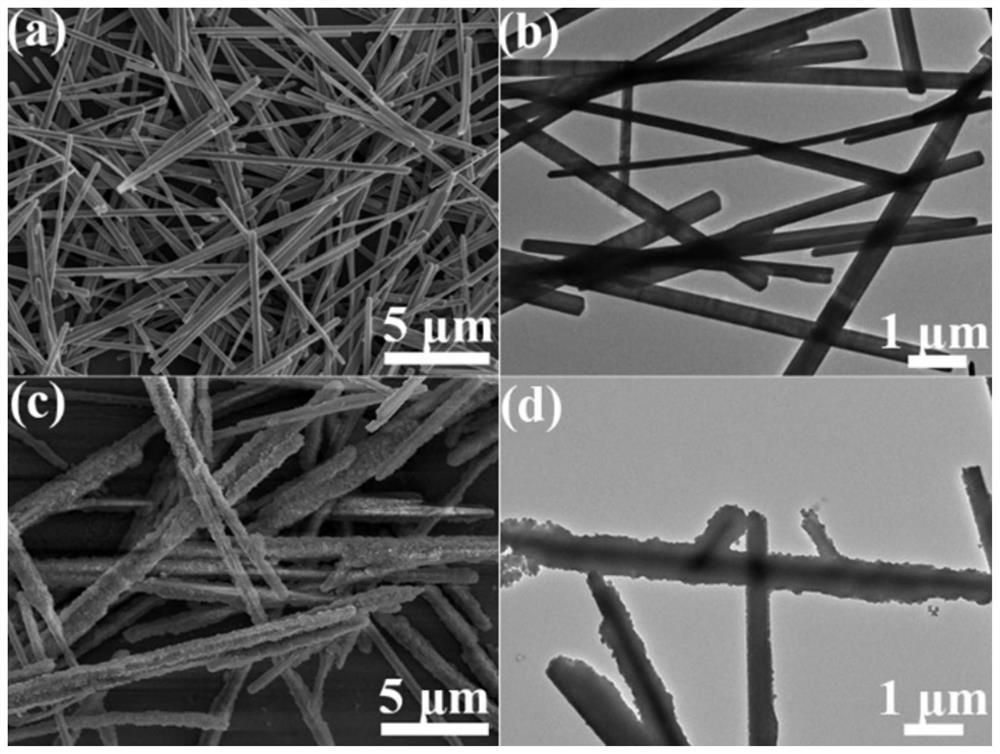

[0050] Weigh 1.05g of ammonium molybdate and dissolve it in a mixed solution of 30ml of concentrated nitric acid and water (composed of 60-70% by weight of concentrated nitric acid and water with a volume ratio of 1:5), stir for 30min and transfer to a 50ml reaction kettle, and then Put it in an oven and react at 200°C for 20h; then wash it three times with deionized water and absolute ethanol, and then dry it in an oven at 60°C for 48h to obtain MoO 3 nanorods, such as figure 1 As shown in a and b, it can be seen that MoO 3 The specifications of the nanorods are: the length is 5-10 μm, and the diameter is 200-500 nm.

preparation example 2

[0052] Preparation of MoPs

[0053] Will MoO 3 The nanorods were heated from 20°C to 800°C at a rate of 3°C / min in an Ar / H2 mixed atmosphere and held for 2 hours, and then cooled to 20°C at a rate of 3°C / min to obtain carbonized products.

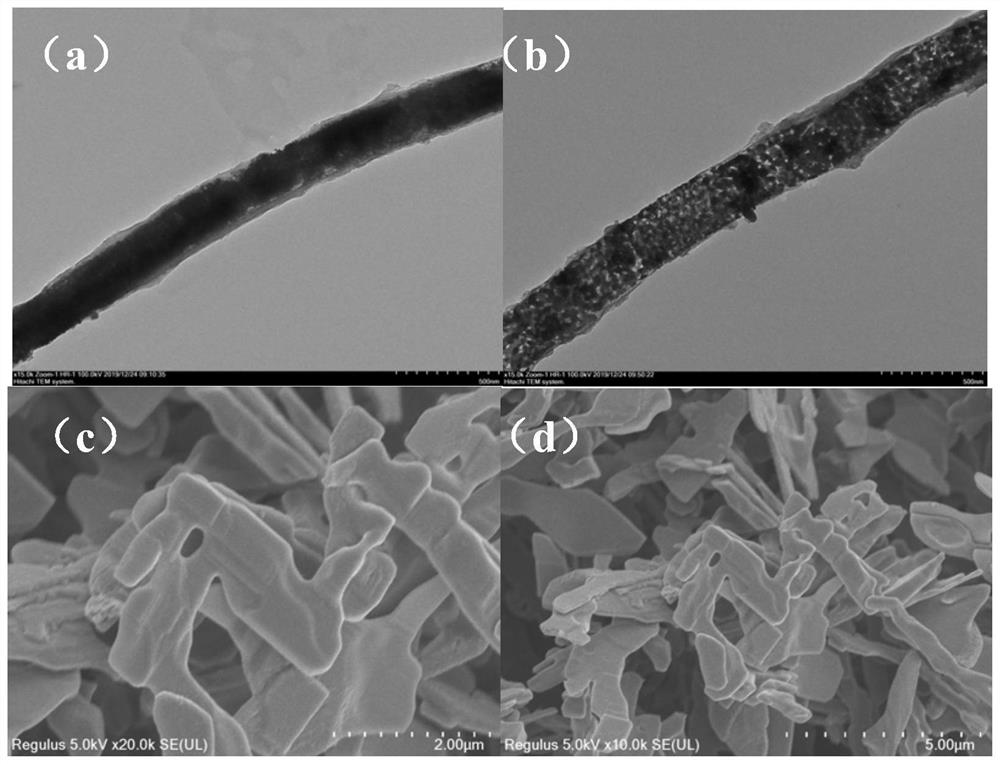

[0054] Then carry out phosphating treatment: under the Ar / H2 mixed atmosphere, the upstream of the quartz boat is 50 mg of diammonium hydrogen phosphate, and the downstream is 10 mg of carbonized products; the temperature is raised from 20 ° C to 800 ° C at a rate of 5 ° C / min and kept for 2 hours, and then Cool down to 20°C at a rate of 5°C / min to obtain MoP, such as figure 2 Shown in c and d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com