Low-cost high-fluidity backfill material and preparation method thereof

A high-fluidity, low-cost technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of low resource utilization rate of phosphogypsum, difficult access to compaction equipment, and poor compaction quality of backfill and other issues, to achieve the effect of large promotion and application potential, high mobility, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

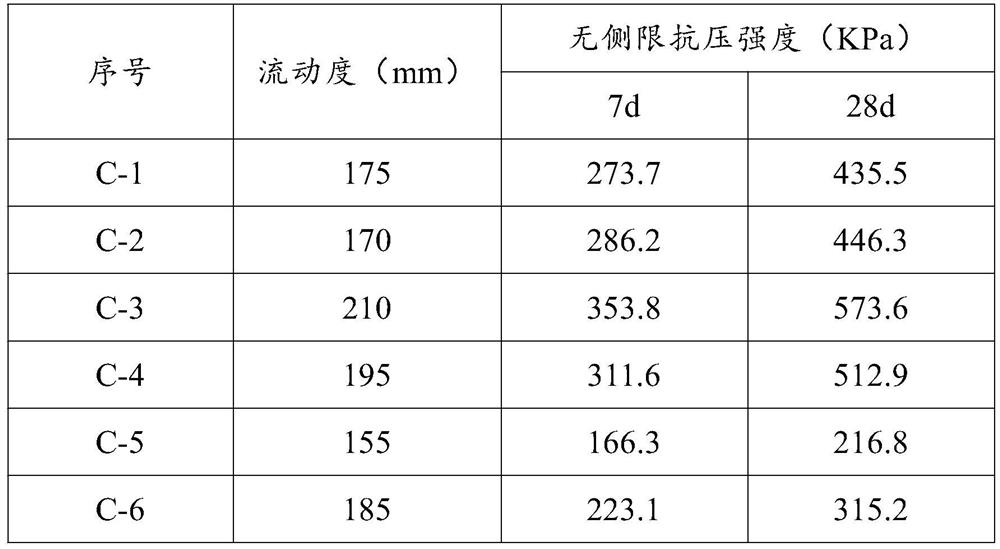

Embodiment 1

[0036] A low-cost high-fluidity backfill material, made of the following raw materials by weight: 100 parts of engineering mud (NJ-1), 5 parts of engineering dregs (ZT-1), 0.5 parts of quicklime, and 10 parts of recycled fine aggregate 1.5 parts of grade II fly ash, 2.5 parts of phosphogypsum, 0.2 parts of sodium sulfate and 3 parts of S95 grade slag powder. The preparation method is as follows: add quicklime to the engineering mud (NJ-1) and stir evenly, drain the supernatant after standing for 6 hours; then add engineering dregs (ZT-1) and continue to stir evenly; finally, add the remaining raw materials and Stir evenly to obtain a mixture with good fluidity, which is the product of the present invention, denoted as C1.

Embodiment 2

[0038] A low-cost and high-fluidity backfill material, made of the following raw materials by weight: 100 parts of engineering mud (NJ-1), 15 parts of engineering dregs (ZT-2), 0.9 parts of quicklime, and 14 parts of recycled fine aggregate 3.0 parts of Class II fly ash, 4.0 parts of phosphogypsum, 0.4 parts of sodium sulfate and 5 parts of S95 grade slag powder. The preparation method is as follows: add quicklime to the engineering mud (NJ-1) and stir evenly, drain the supernatant after standing for 8 hours, then add engineering dregs (ZT-2) and continue to stir evenly, finally, add the remaining raw materials and mix Stir evenly to obtain a mixture with good fluidity, which is the product of the present invention, denoted as C2.

Embodiment 3

[0040] A low-cost and high-fluidity backfill material, made of the following raw materials by weight: 100 parts of engineering mud (NJ-2), 22 parts of engineering dregs (ZT-3), 1.4 parts of quicklime, and 18 parts of recycled fine aggregate 4.0 parts of Class I fly ash, 6.0 parts of phosphogypsum, 0.6 parts of sodium sulfate and 8 parts of S105 grade slag powder. The preparation method is as follows: add quicklime to the engineering mud (NJ-2) and stir evenly, drain the supernatant after standing for 9 hours, then add engineering slag (ZT-3) and continue to stir evenly, finally, add the remaining raw materials and mix Stir evenly to obtain a mixture with good fluidity, which is the product of the present invention, denoted as C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com