Wave energy conversion semi-physical simulation test bed

A semi-physical simulation, wave energy technology, applied in the direction of fluid dynamics test, conversion sensor output, machine/structural component testing, etc., can solve the problems of accuracy error, large model test cost, etc. The effect of reducing test cost and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

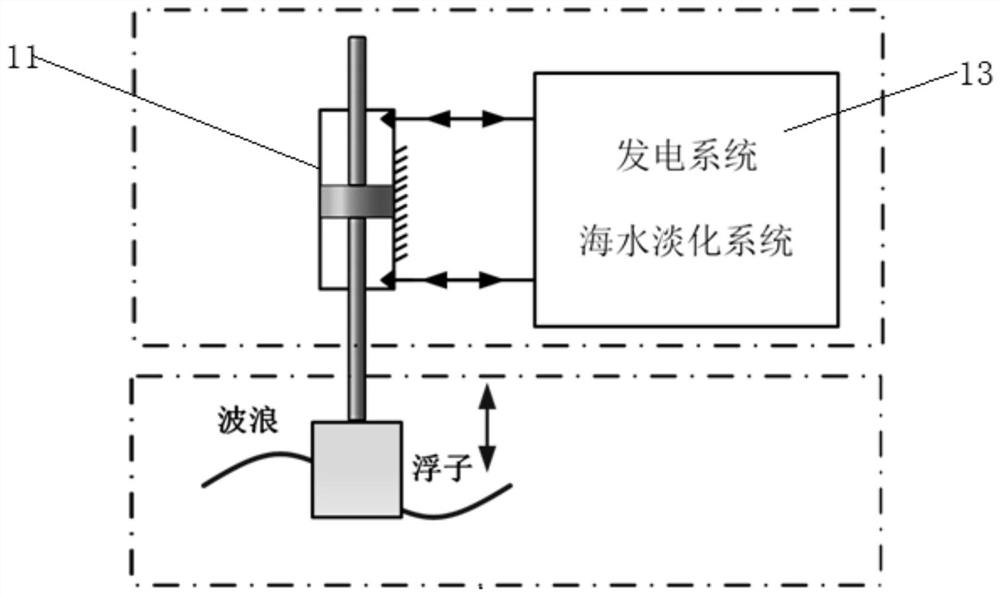

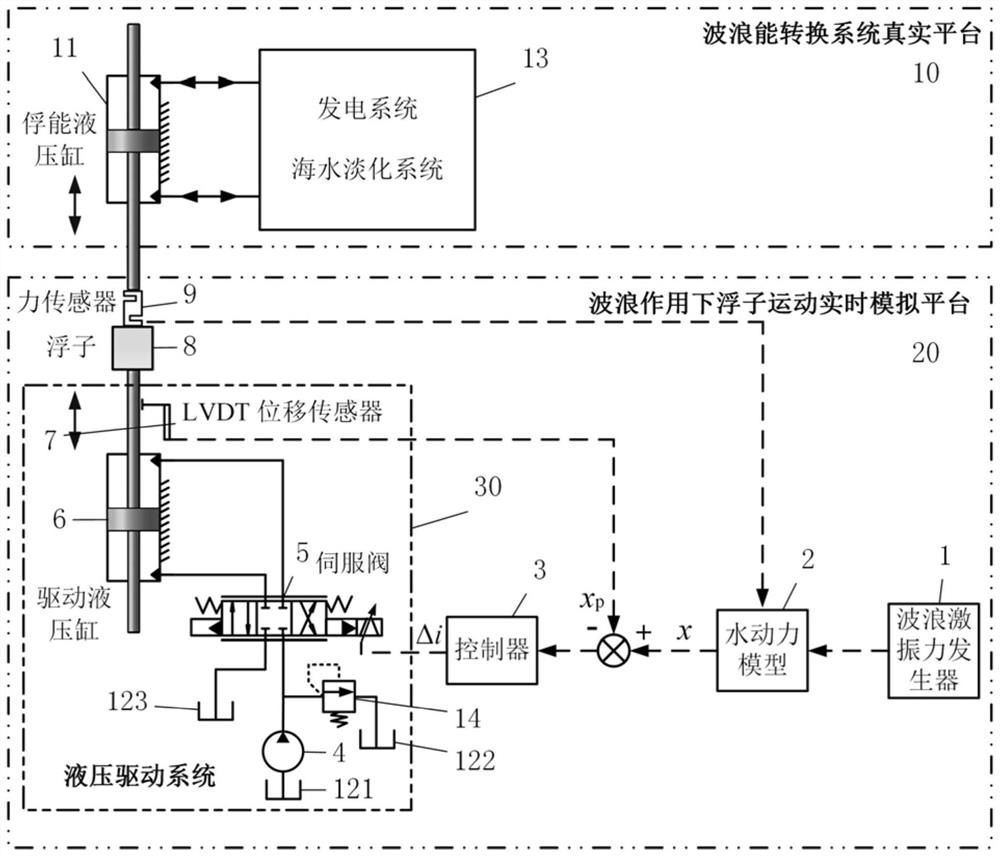

[0031] Such as figure 1 , 2 As shown, a semi-physical simulation test bed for wave energy conversion includes a real platform 10 for the wave energy conversion system and a real-time simulation platform 20 for floater motion under the action of waves. The real platform 10 for the wave energy conversion system includes an energy capture hydraulic cylinder 11, a wave Energy generation system or seawater desalination system 13, the real-time simulation platform 20 of the float movement under the action of waves includes a wave excitation force generator 1, a hydrodynamic model 2, a controller 3, a float 8, a force sensor 9, and a hydraulic drive system 30, The hydraulic drive system 30 includes a hydraulic pump 4 , an overflow valve 14 , an oil tank, an electro-hydraulic servo valve 5 , a driving hydraulic cylinder 6 , and an LVDT displacement sensor 7 .

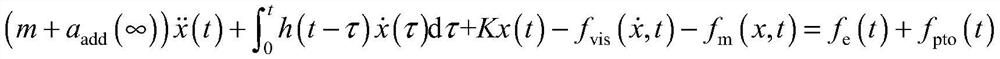

[0032] Hydrodynamic model 2 is a mathematical model that reflects the interaction between the buoy and the waves in the ocea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com