A kind of preparation method of high flux low pressure reverse osmosis membrane

A low-pressure reverse osmosis, high-flux technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of high driving pressure, and achieve the effect of low driving pressure, high porosity and high flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

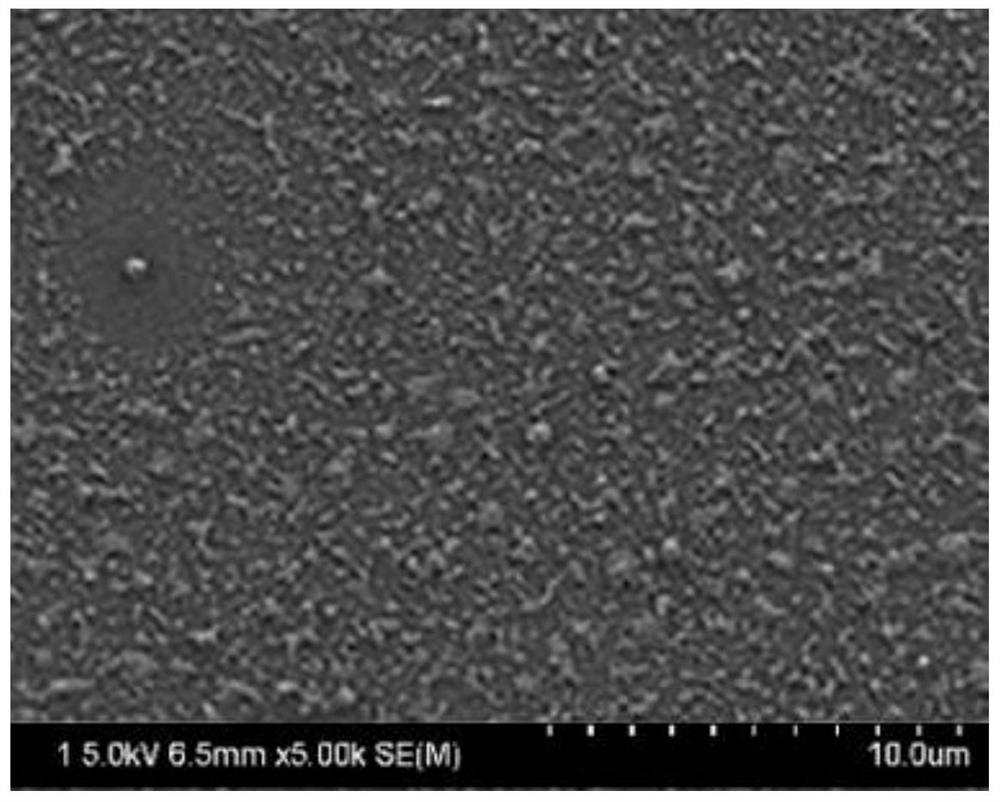

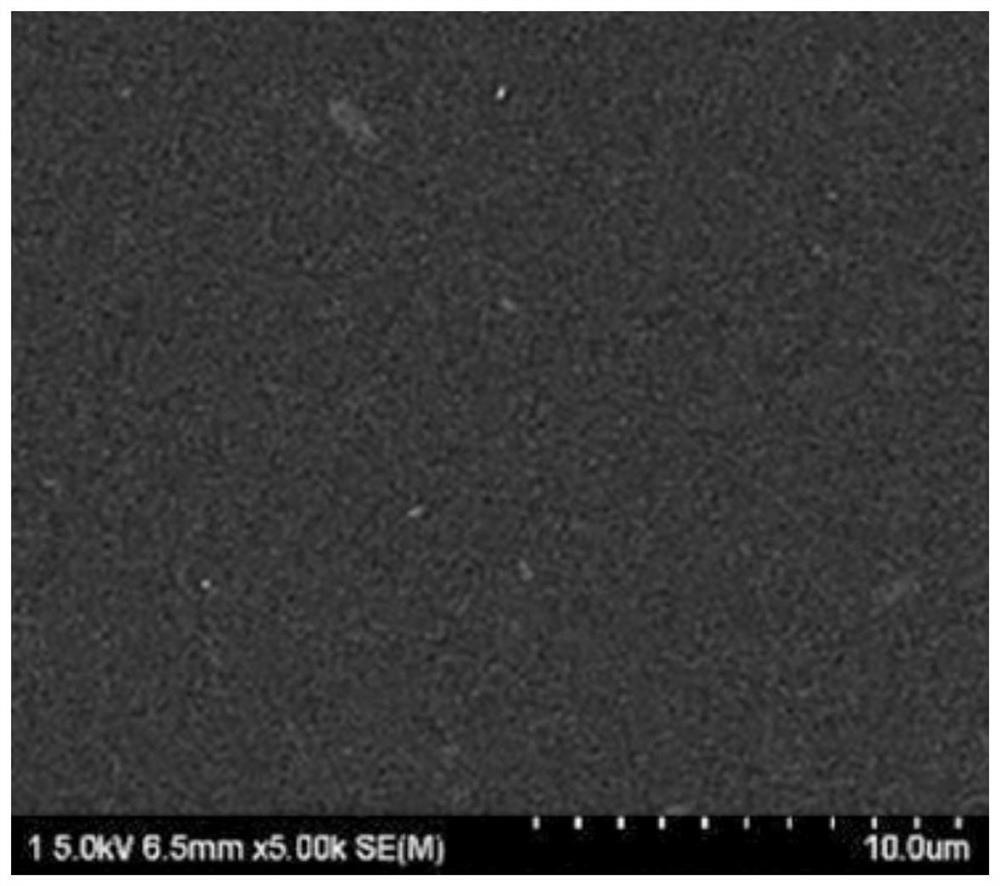

Image

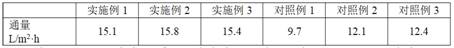

Examples

Embodiment 1

[0028] The first step, preparation of modified base membrane: in parts by weight, take polysulfone (weight average molecular weight is 1 × 10 5 ~1×10 6 ) 15 parts, 2 parts of polyhydroxypropyl dimethyl ammonium chloride, and 20 parts of N-methylpyrrolidone were mixed, and the temperature was raised to 50 ° C and mixed evenly, and then defoamed to obtain a casting solution; On a flat plate with a thickness of 200 μm, it was then immersed in deionized water of a coagulation bath at 40°C for phase separation to obtain a modified polysulfone membrane;

[0029] The second step, the preparation of the intermediate layer: in parts by weight, disperse 2 parts of nano-silica in 80 parts of ethanol, then dropwise add 1 part of p-hydroxybenzoic acid under nitrogen protection, react at 25 ° C for 6 hours, and then add the solid Centrifugal separation, washing with ethanol and deionized water, and freeze-drying to obtain modified silica nanoparticles; mixing modified silica nanoparticles,...

Embodiment 2

[0032] The first step, preparation of modified base membrane: in parts by weight, take polysulfone (weight average molecular weight is 1 × 10 5 ~1×10 6 ) 18 parts, 4 parts of polyhydroxypropyl dimethyl ammonium chloride, and 70 parts of N-methylpyrrolidone were mixed, and the temperature was raised to 80 ° C and mixed evenly, and then defoamed to obtain a casting liquid; On a flat plate, the thickness is 200 μm, and then immersed in deionized water in a coagulation bath at 80 °C for phase separation to obtain a modified polysulfone membrane;

[0033] The second step, the preparation of the intermediate layer: in parts by weight, disperse 5 parts of nano-silica in 90 parts of ethanol, then dropwise add 3 parts of p-hydroxybenzoic acid under nitrogen protection, react at 40 ° C for 10 hours, and then add the solid Centrifugal separation, washing with ethanol and deionized water, and freeze-drying to obtain modified silica nanoparticles; mixing modified silica nanoparticles, dis...

Embodiment 3

[0036] The first step, preparation of modified base membrane: in parts by weight, take polysulfone (weight average molecular weight is 1 × 10 5 ~1×10 6 ) 16 parts, 3 parts of polyhydroxypropyl dimethyl ammonium chloride, and 40 parts of N-methylpyrrolidone were mixed, the temperature was raised to 60 ° C and mixed evenly, and then defoamed to obtain a casting liquid; On a flat plate with a thickness of 200 μm, it was then immersed in deionized water of a coagulation bath at 65°C for phase separation to obtain a modified polysulfone membrane;

[0037] The second step, the preparation of the intermediate layer: in parts by weight, disperse 4 parts of nano-silica in 85 parts of ethanol, then add 2 parts of p-hydroxybenzoic acid dropwise under nitrogen protection, react at 35 ° C for 8 hours, and then add the solid Centrifugal separation, washing with ethanol and deionized water, and freeze-drying to obtain modified silica nanoparticles; mixing modified silica nanoparticles, disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com