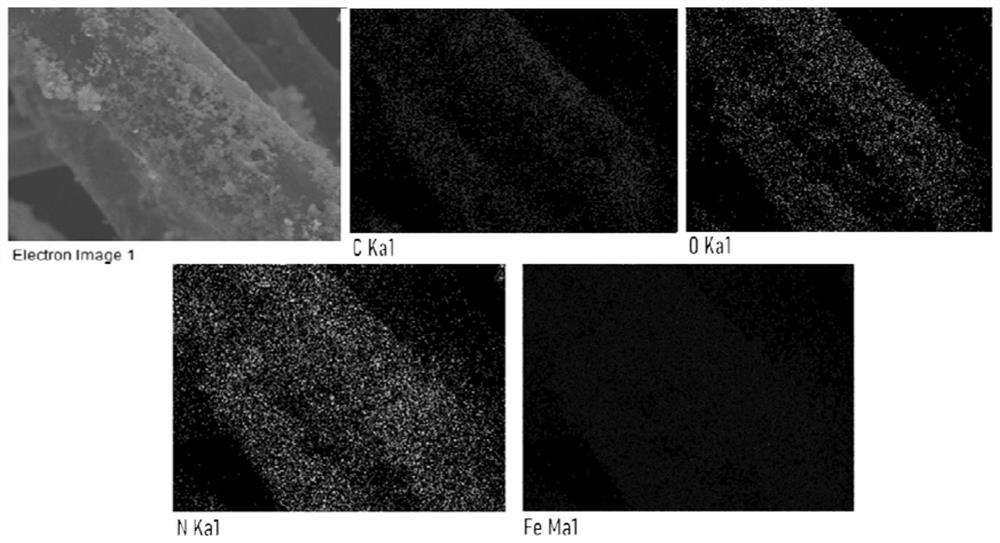

Preparation method and application of biomass carbon-based Fe single atom-N doped porous carbon material

A technology of porous carbon material and nitrogen-doped porous carbon, which is applied in the fields of carbon preparation/purification, botanical equipment and method, application, etc., can solve the problems of polluted environment, poor degradation effect and high preparation cost, and achieves a simple preparation method , cost reduction, the effect of improving the light and heat absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Embodiment 1: This embodiment is a method for preparing a biomass carbon-based Fe single atom-N doped porous carbon material, which is completed according to the following steps:

[0028] 1. Preparation of walnut shell-based nitrogen-doped porous carbon materials:

[0029] ①. Mix walnut shell charcoal powder, urea, o-phenylenediamine and potassium hydroxide, and then ball mill to obtain mixture I;

[0030] ② Put the mixture Ⅰ into the alumina porcelain boat, then put the alumina porcelain boat into the tube furnace, pass inert gas into the tube furnace at room temperature, and then inert gas atmosphere at 3°C / min~ Raise the temperature to 250℃~350℃ at a heating rate of 5℃ / min, keep it for 1h~2h, then raise the temperature to 750℃~800℃ at a heating rate of 3℃ / min~5℃ / min, keep it for 1.5h~2.5h, and finally Cool to room temperature to obtain reaction product I;

[0031] ③, first use hydrochloric acid to wash the reaction product I, then use distilled water to wash the re...

specific Embodiment approach 2

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the walnut shell charcoal powder described in step one 1. is to be finished according to the following steps:

[0046] (1) Wash the walnut shells with distilled water until the distilled water is free of turbidity, then dry them at 60°C to 70°C to constant weight, crush them with a grinder, and sieve them with a 200-mesh stainless steel screen to obtain a particle size of less than 200 mesh walnut shell powder;

[0047] (2), firstly put the walnut shell powder into the reaction kettle, then add deionized water, hydrogen peroxide solution and acetic acid, then conduct a hydrothermal reaction at a temperature of 80°C to 200°C for 2h to 24h, cool to room temperature, and obtain the reaction Product: Suction filtration is carried out using a vacuum filtration device, and the obtained solid matter is dried at a constant temperature at 50°C to 70°C for 10h to 12h to obtain walnut s...

specific Embodiment approach 3

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ball milling speed described in step one ① is 500r / min~1000r / min, and the ball milling time is 0.5h~1.5h; step one The mass ratio of walnut shell charcoal powder, urea, o-phenylenediamine and potassium hydroxide described in ① is 1:1.5:0.5:2. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com