Method for preparing PZT ferroelectric ceramic with periodic pore structure through 3D printing

A ferroelectric ceramic, 3D printing technology, applied in the direction of additive processing, etc., to achieve the effect of simple preparation process, controllable uniform distribution, and controllable porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

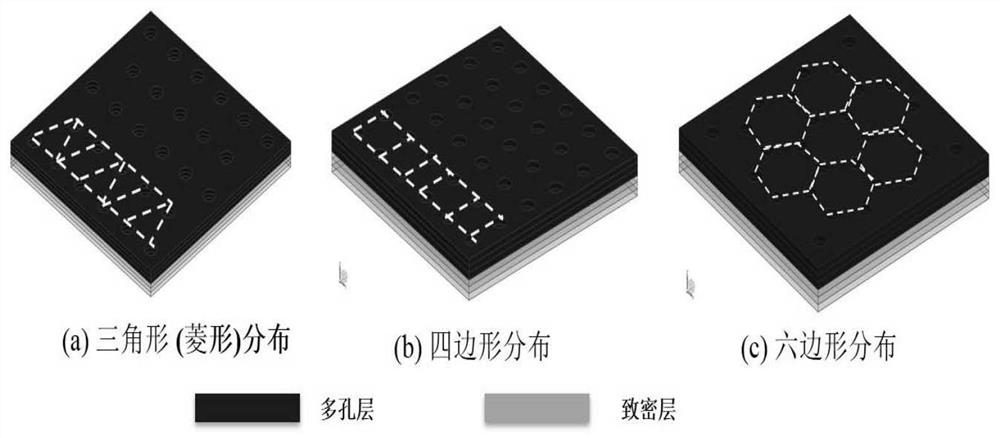

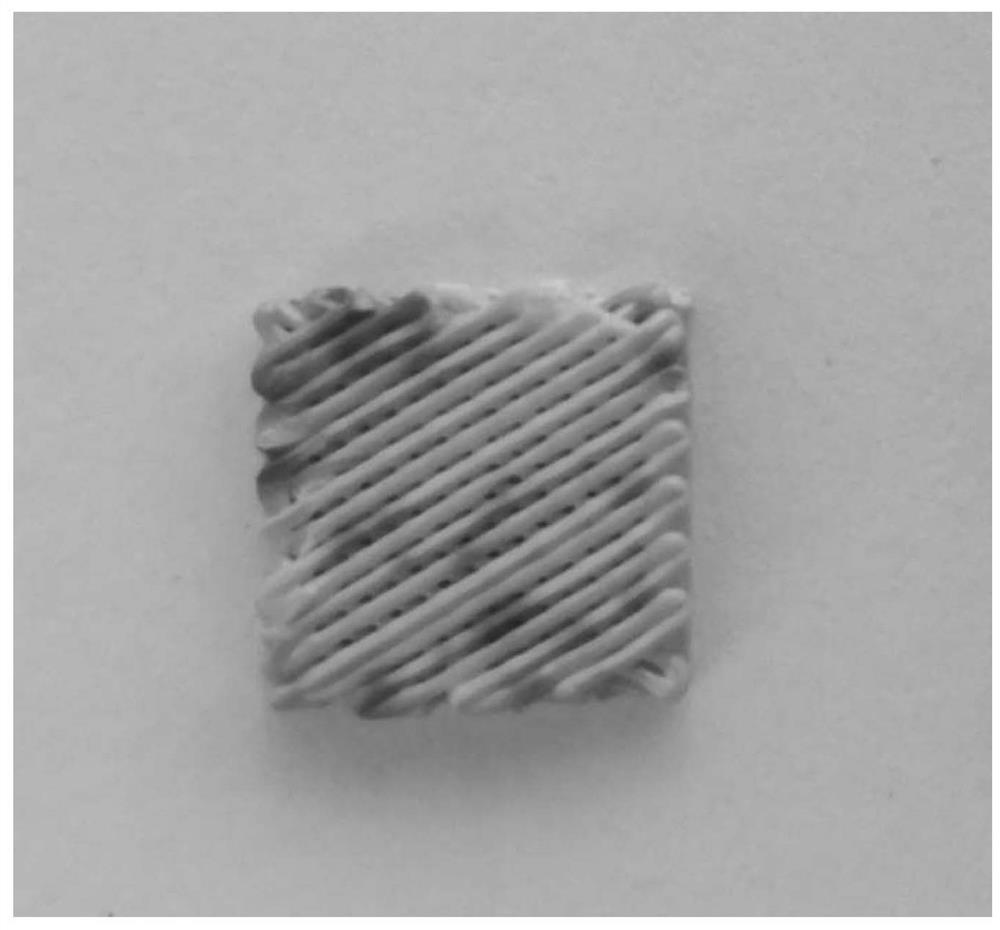

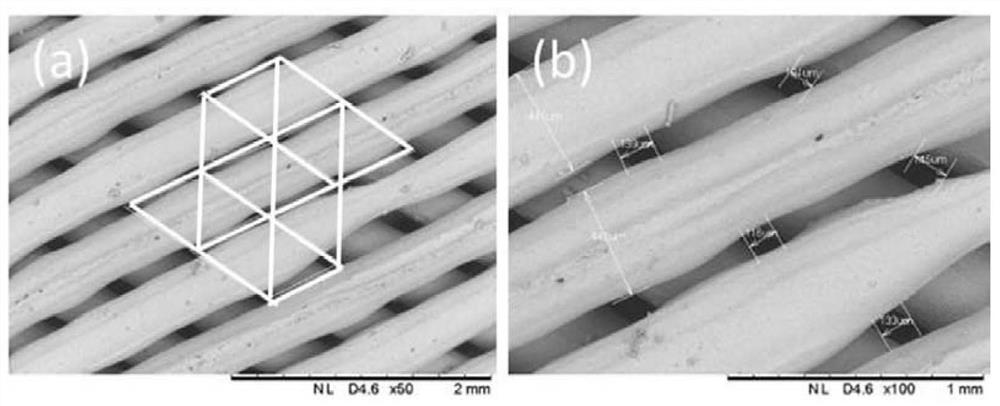

[0043] Example 1 3D printing of PZT ferroelectric ceramics with periodic pore structure in triangular (rhombic) distribution According to the designed periodic triangular (rhombic) micropore distribution structure: first print a dense layer, and build a triangular (rhombic) distribution on the dense layer The porous layer is then constructed into a dense layer to form a periodic porous ceramic unit; then different units are stacked layer by layer, or different units are combined to obtain a 3D scaffold of porous PZT ferroelectric ceramics with the target periodic pore structure.

[0044] Specifically, use drawing software such as 3dMax to design a cube model with a height of 4.48 cm and a length and width of 1 cm, write corresponding programs, and export it as an stl file. Utilizes the fourth generation 3D Bioplotter TM The software that comes with the equipment slices it. The thickness of the slice is 0.32mm, and there are 14 layers in total, of which the first and second lay...

Embodiment 2

[0050] Example 2 3D printing of PZT ferroelectric ceramics with periodic pore structure in quadrilateral distribution According to the designed periodic quadrilateral microporous distribution structure: first print a dense layer, build a porous layer with periodic quadrilateral distribution on the dense layer, and then build a dense layer to form a periodic porous ceramic unit; then different units are stacked layer by layer, or different units are combined to obtain a 3D scaffold of porous PZT ferroelectric ceramics with the target periodic pore structure.

[0051] Specifically, use drawing software such as 3dMax to design a cube model with a height of 4.48 cm and a length and width of 1 cm, write corresponding programs, and export it as an stl file. Utilizes the fourth generation 3D Bioplotter TM The software that comes with the equipment slices it. The thickness of the slice is 0.32mm, and there are 14 layers in total. Among them, the 1st-5th layer and the 9th-14th layer ar...

Embodiment 3

[0056] Example 3 3D printing PZT ferroelectric ceramics with hexagonal distribution of periodic pores According to the designed periodic hexagonal micropore distribution structure: first print the dense layer, and build periodic hexagonal distribution of pores on the dense layer layer, and then build a dense layer to form a periodic porous ceramic unit; then different units are superimposed layer by layer, or different unit combinations, to obtain a 3D scaffold of porous PZT ferroelectric ceramics with the target periodic pore structure.

[0057] Specifically, use drawing software such as 3dMax to design a cube model with a height of 4.48 cm and a length and width of 1 cm, write corresponding programs, and export it as an stl file. Utilizes the fourth generation 3D Bioplotter TM The software that comes with the equipment slices it, the thickness of the slice is 0.32mm, a total of 1 layer, of which the 1st-3rd layer and the 8th-10th layer are dense layers, and the middle 4 laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com