Preparation for nano-oxide powder

A nano-oxide and oxide technology, which is applied in the preparation of oxide/hydroxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve problems such as agglomeration, and achieve narrow distribution, regular morphology and simple device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

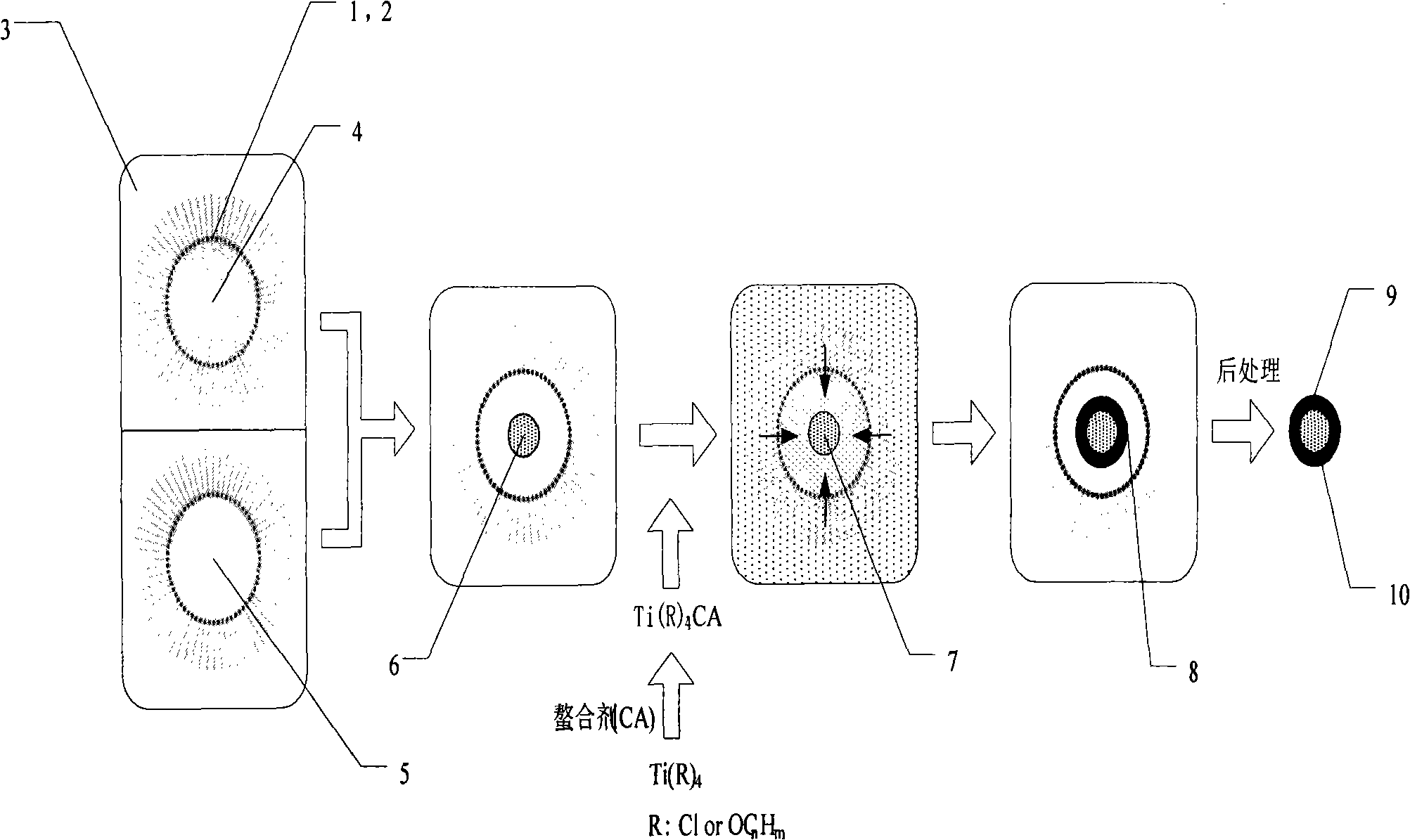

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Nano TiO 2 Powder preparation

[0018] 19.74g n-hexane, 21.20gTX-100, 13.40g n-hexanol, 1.77gH 2 O mixing, ultrasonic dispersion to prepare a transparent and uniform microemulsion system. Mix 13.16g of n-hexane, 0.98g of acetylacetone and 11.15g of tetrabutyl titanate, ultrasonically disperse them and add them into the microemulsion system while stirring rapidly. When the gel appears, continue to react for a period of time, then take it out and centrifuge it. Alternately washed with acetone and ethanol, dried and calcined at 500°C to obtain TiO 2 The particle size of the powder is 10-15nm.

Embodiment 2

[0019] Example 2 Nano-SiO 2 Powder preparation

[0020] 14.81g n-hexane, 15.90gTX-100, 10.05g n-hexanol, 3.10gH 2 O mixing, ultrasonic dispersion to prepare a transparent and uniform microemulsion system. Mix 13.16g of n-hexane, 1.72g of acetylacetone and 11.92g of ethyl orthosilicate, ultrasonically disperse and add to the microemulsion system while stirring rapidly, and continue stirring for a period of time after the addition. Move it into an autoclave at 120°C to continue the reaction until gel appears, then take it out and centrifuge it, wash it alternately with acetone and ethanol, dry it, and calcinate it at 600°C to get SiO 2 The particle size of the powder is 16-25nm.

Embodiment 3

[0021] Example three Nano ZrO 2 Powder preparation

[0022] 29.61g n-hexane, 15.90gTX-100, 5.02g n-hexanol alcohol, 2.65gH 2 O mixing, ultrasonic dispersion to prepare a transparent and uniform microemulsion system. Mix 9.87g of n-hexane, 1.48g of acetylacetone and 8.76g of zirconium oxychloride, ultrasonically disperse them and add them into the microemulsion system while stirring rapidly to fully react. After adding acetone to form a gel, take it out and centrifuge it, wash it alternately with acetone and ethanol, dry it, and calcinate it at 550°C to get ZrO 2 The particle size of the powder is 12-20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com